Noise reducer for air conditioner, filter and filter drying

A technology for air conditioners and filter screens, which is applied in the fields of three types of pipeline connectors: filters, mufflers, and dry filters. It can solve the problems of rising air conditioner manufacturing costs and economic burdens on consumers, and achieve weight reduction and manufacturing costs. Reduced, ease-of-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

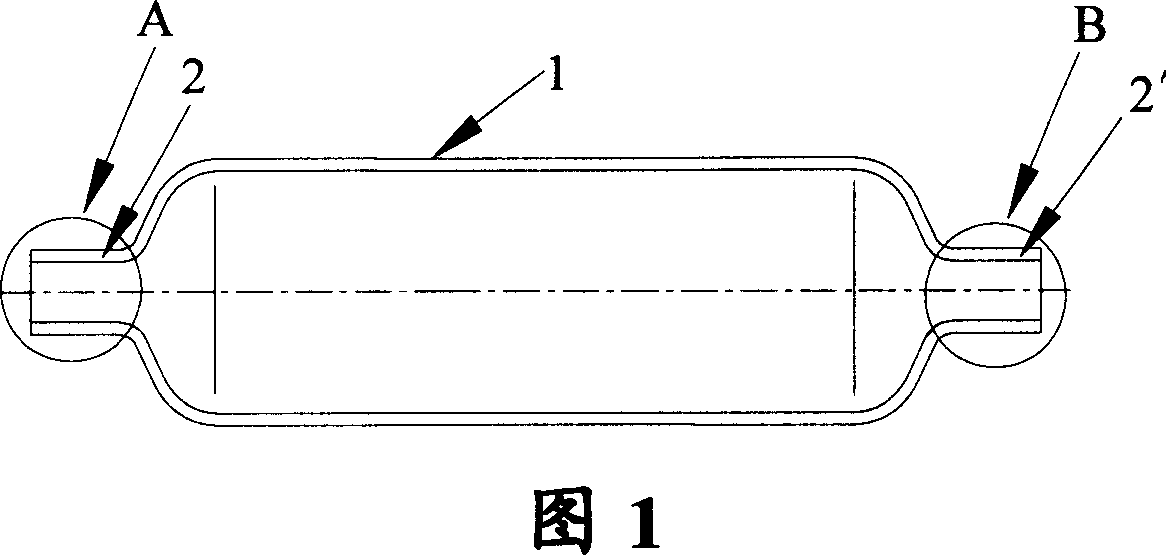

[0020] Referring to Fig. 1, what is shown in the figure is the muffler in the prior art, the difference of this embodiment is that its whole body (including cylinder 1 and necking 2, 2') is made of magnesium alloy material, but in Copper plating is applied to the straight sections at the two ends of the shrinkage 2 and 2'.

Embodiment 2

[0022] Referring to Fig. 4, the muffler is shown in the figure, and its difference from Fig. 1 is that the copper connection parts at both ends of the cylinder are copper sleeves 3, 3' welded on the outer surfaces of the shrinkages 2, 2'.

[0023] As an alternative to Embodiment 2, one or all of the copper sleeves 3, 3' in FIG. 4 are replaced by aluminum alloy sleeves.

Embodiment 3

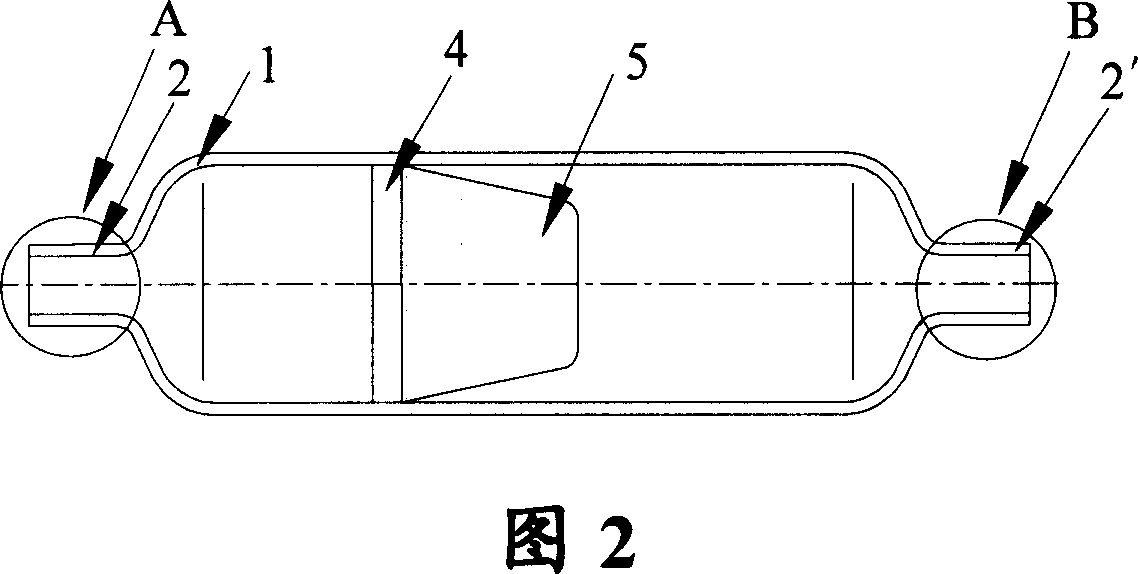

[0025] Referring to Fig. 2, what is shown in the figure is the filter in the prior art, the difference of this embodiment is that the cylinder body 1 and the filter screen frame 4 in this embodiment are made of magnesium alloy material, and the filter screen The wire 5 is made of stainless steel, and a copper layer (not shown in the figure) is added to the straight section of the shrinkage part 2 at both ends of the cylinder body 1 by copper plating. In this embodiment, as an alternative, the screen frame 4 can be replaced by magnesium material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com