Method of preparing tea extract and tea flavor

A technology of tea extracts and tea leaves, which is applied in the field of enzyme treatment of tea extracts and tea spices, and can solve problems such as insufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

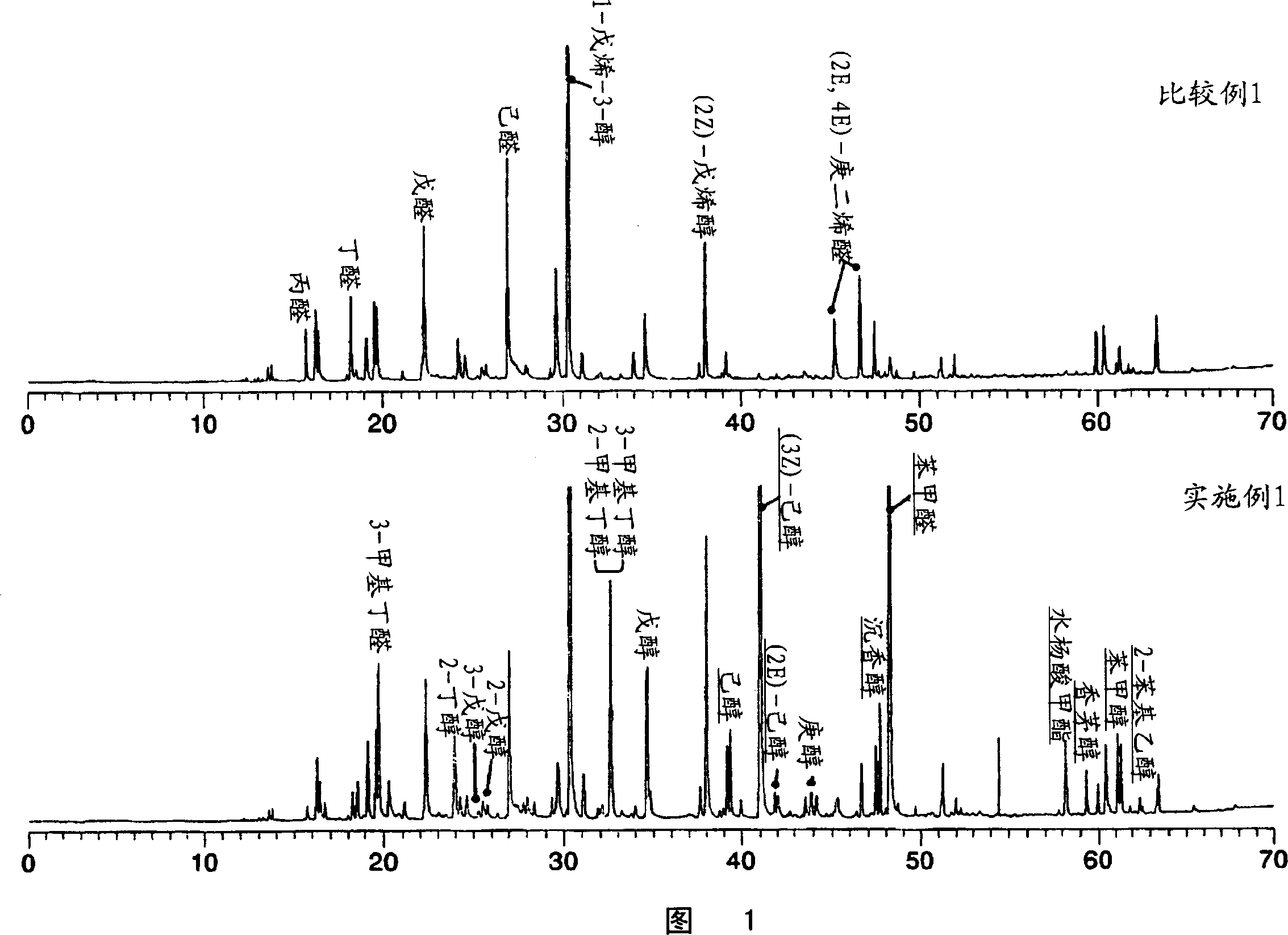

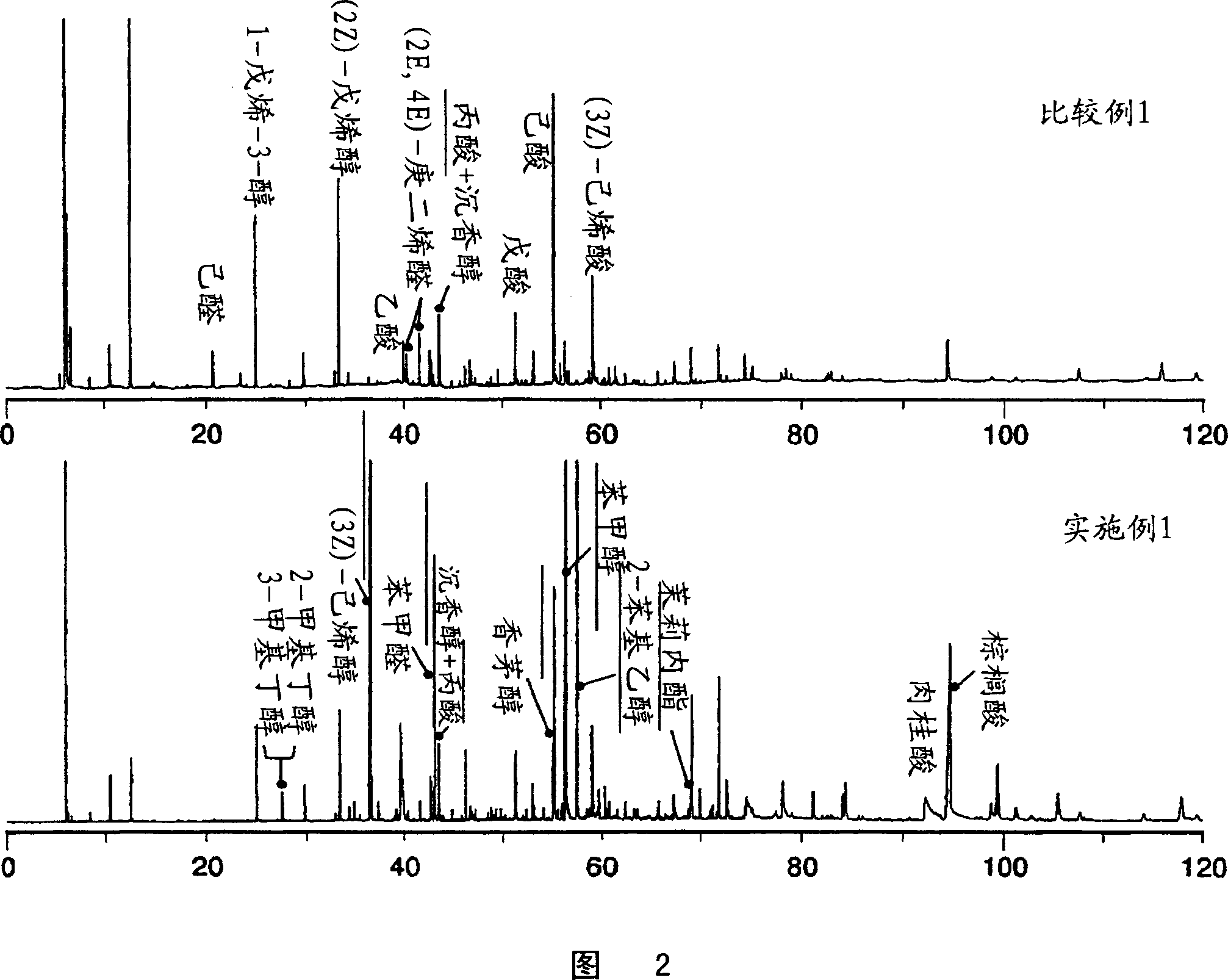

Image

Examples

Embodiment 1

[0037] Add 378g of soft water (60°C) and 0.09g of sodium ascorbate to 30g of green tea leaves, heat up to 80°C for sterilization, and cool to 40°C. Add 0.04g tannase (manufactured by KIKKOMAN company), 0.1g protease A (manufactured by Amano Enzyme company), 5U laetriase (manufactured by Sigma Aldrich company) and 5U β-xylosidase (manufactured by Sigma Aldrich company) to which, at 40 Stand at ℃ for 4 hours to react, filter and separate the tea leaves and the extract, and obtain 340 g of green tea extract.

Embodiment 2

[0060] With the same treatment as in Example 1, but the enzyme uses 0.04g tannase (manufactured by KIKKOMAN company), 5U amygdalin (manufactured by Sigma Aldrich company) and 5U β-xylosidase (manufactured by Sigma Aldrich company), to obtain 338g green tea extract things.

Embodiment 3

[0072] 50 g of Darjeeling tea leaves were mixed with 750 g of soft water under stirring, and after being heated to 80° C., cooled to 40° C. To this was added 0.01 g of tannase (manufactured by KIKKOMAN), 0.1 g of protease A (manufactured by Amano Enzyme) and 0.1 g of AROMAZYME (β-glucosidase, made by SHALIGAL), and the reaction was stirred at 40° C. for 6 hours. It was filtered through kapok cloth to obtain 690 g of filtrate. Then sterilize at 90° C. for 10 minutes, cool to 40° C., centrifuge (centrifugal acceleration 800 G×5 minutes), and filter the supernatant with filter aid diatomaceous earth to obtain 660 g of clarified filtrate (B×3.6°).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com