Drum washing machine

A drum-type washing machine and drum technology, which can be applied to other washing machines, washing machines with containers, washing devices, etc., can solve problems such as failures, temperature rise of electronic components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

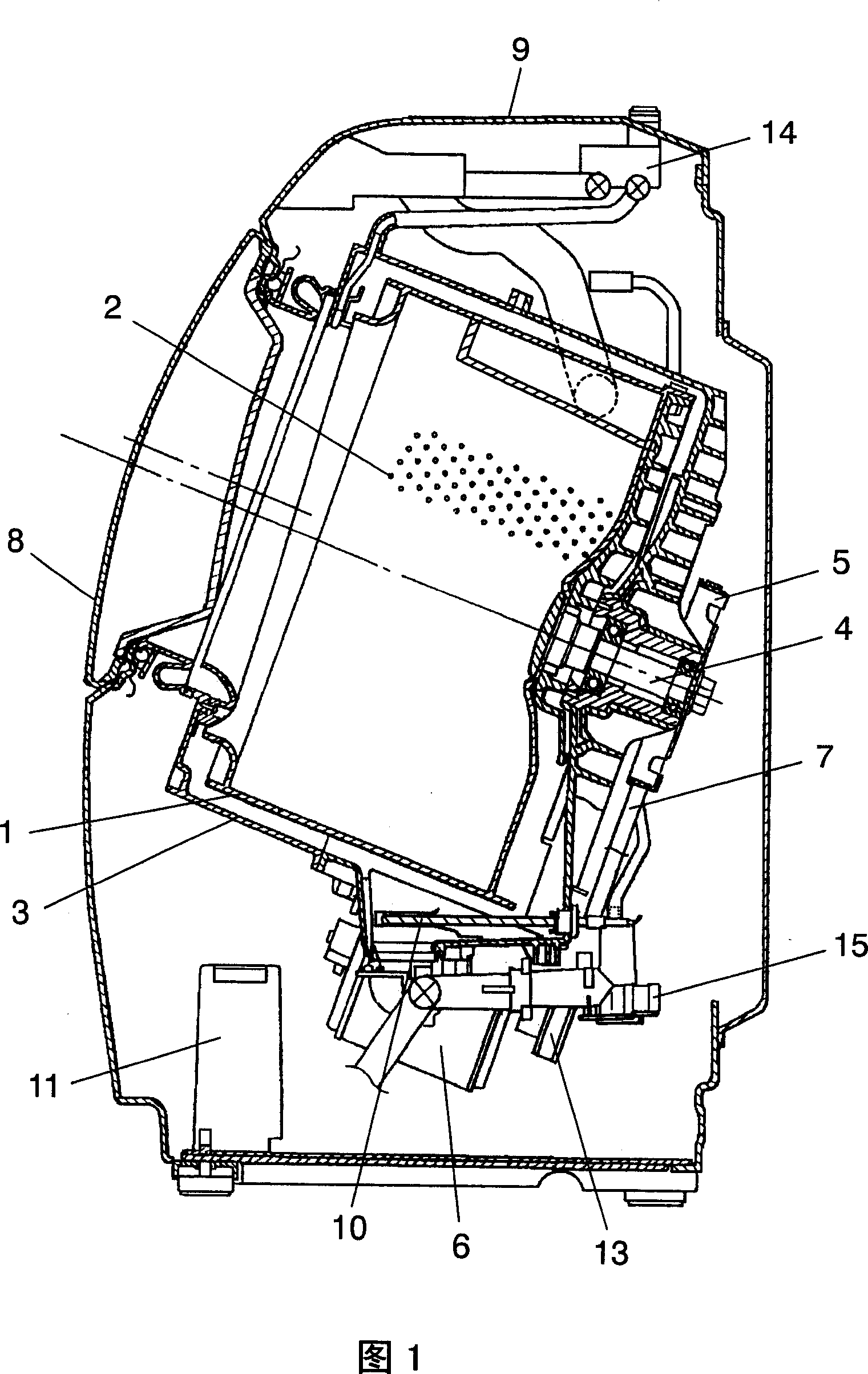

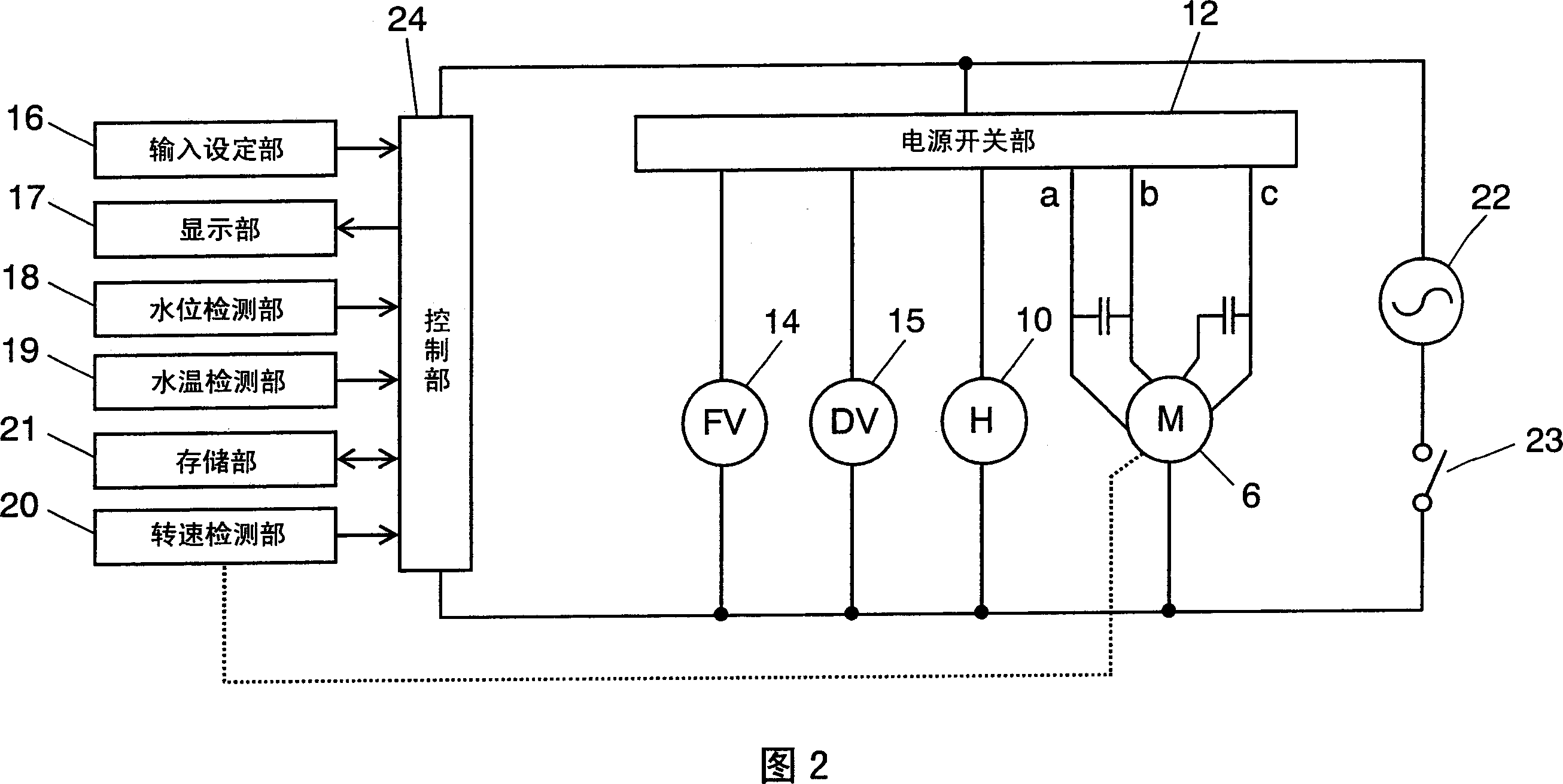

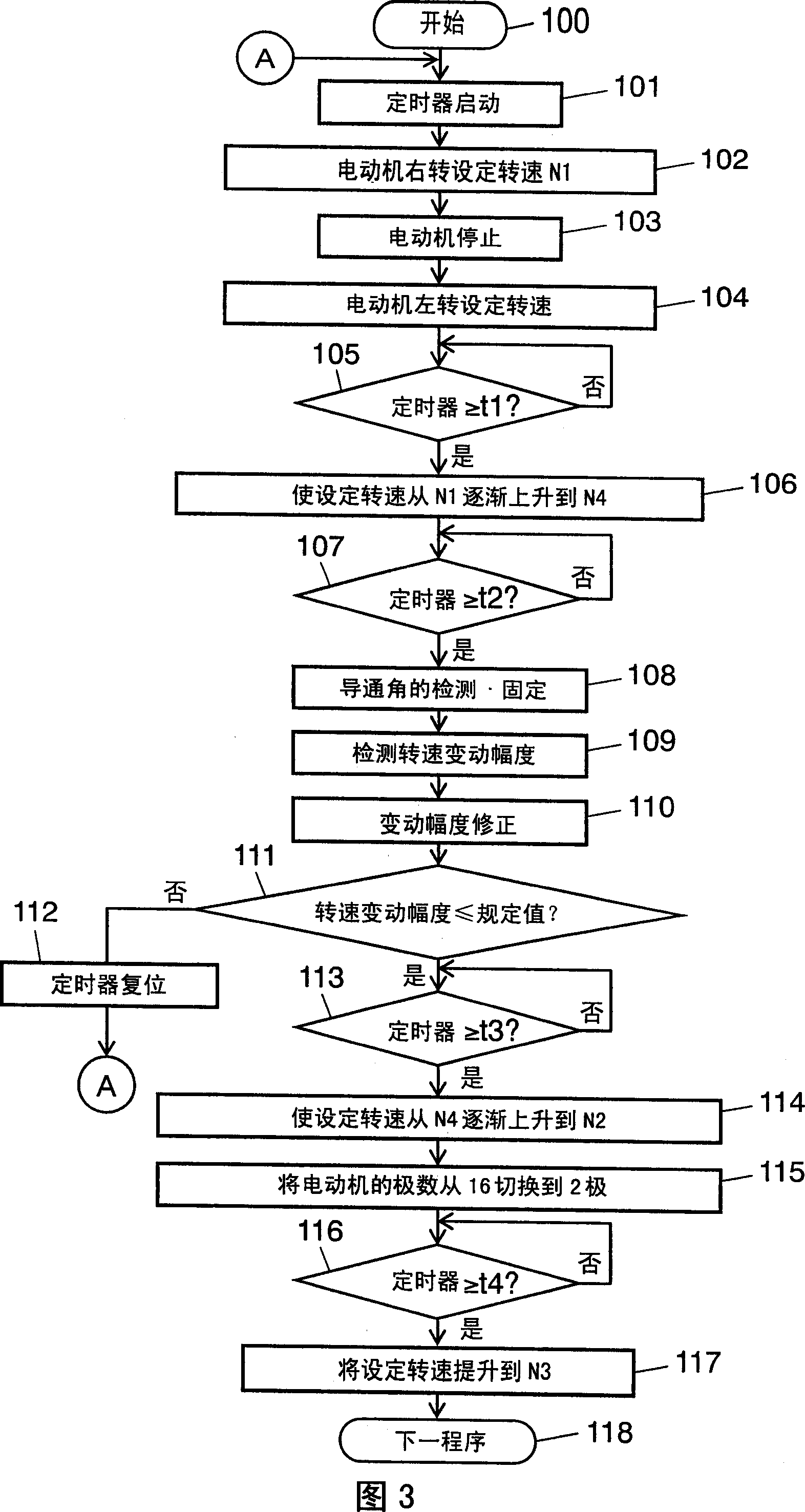

Embodiment Construction

[0011] The present invention provides a drum-type washing machine, comprising: a drum that receives laundry and is driven to rotate with the horizontal or inclined direction as the rotation axis, a motor that drives the drum with more than two poles, and a device that controls the motor. Speed control unit. The control unit is configured to apply from the smallest conduction angle at which the motor can be driven when changing the number of poles of the motor to change the rotational speed. According to this configuration, by reducing the overcurrent generated when the drum is raised from a low speed to a high speed during the dehydration process, temperature rise of electronic components such as the motor and the power switch unit for driving the motor can be suppressed. In addition, since the current is reduced, low-cost products can also be used for motors and electronic components.

[0012] Hereinafter, embodiments of the present invention will be described with referen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com