Purified polyoxypropylene/polyoxyethylene copolymers and method of preparing the same

A polyoxyethylene and polyoxypropylene technology, which is applied in the field of refined polyoxypropylene/polyoxyethylene copolymers to achieve better control of the biological activity range and lower risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

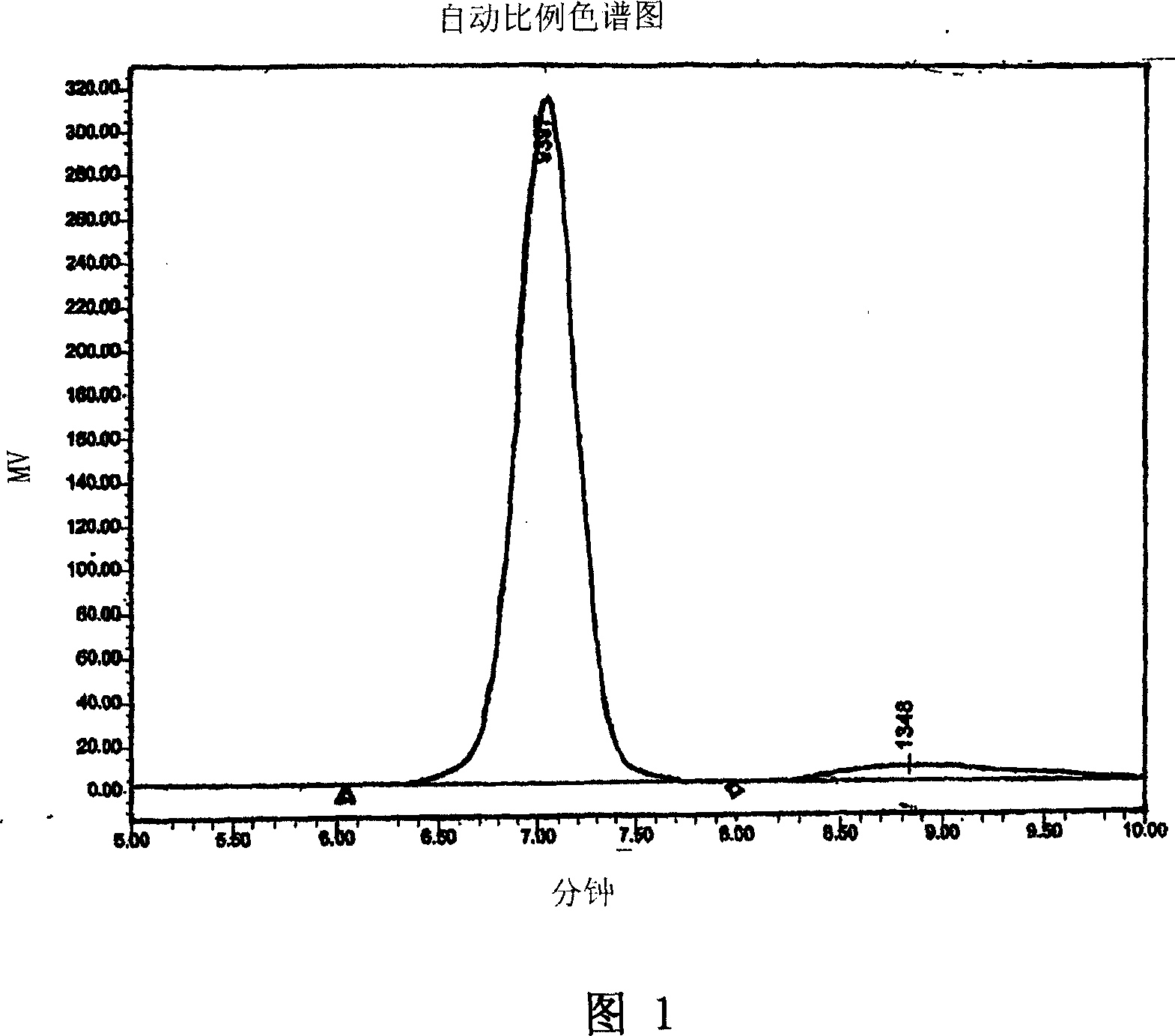

[0057] The chemical properties of an octa-unit copolymer sold by BASF Corporation under the brand name CRL-8761 were determined by first blending the copolymer in a steel drum shipping container. This was achieved by rolling the drum horizontally on the mill at 30 rpm for two hours. A small portion of the homopolymer is then siphoned and delivered into glass vials. Two samples were removed from the vials and the samples were tested using the following high performance liquid chromatography (HPLC) equipment: Waters 510, 717Plus autosampler, Styragel columns at 500A and 1000A, and 410RI detector. The mobile phase THF was 1.0 ml per minute. Each sample was injected twice, and each sample was injected repeatedly on the following day. The main high molecular weight peak and the low molecular weight peak of the two samples were calculated using PEG standards. The average peak molecular weight of the main peak for both samples was 9283 Daltons. The low molecular weight average pe...

example 2

[0060] The relative permeability or water absorption of the low molecular weight component and the high molecular weight component in the copolymer was studied using the commercially available CRL-8761 mentioned above. In this study, cell culture experiments were performed with the Caco2 cell line, which is commonly used to study passive drug uptake. Specifically, the Caco2 cell line was used to identify how and at what rate CRL-8761 crosses the intestinal epithelium. After an initial equilibration period, 6-7×10 4 The Caco2 cell line was seeded on the polyester membrane cell culture insert, that is, the polycarbonate membrane (Costar Transwell-Clear) 3470 had a hole size of 0.4um and a growth area of 0.33cm 2 . The inner and outer lumens of the insert were filled with 0.4 ml and 0.5 ml of cell culture medium (Vitacell Minimum Essential Medium alpha-Sigma Corporation-M0894-3H172), 10% fetal calf serum and 1% antibiotic solution, respectively. The well plates with the inse...

example 3

[0062] Dissolve CRL-8761 directly in the cell culture medium with a stirrer at a concentration of about 10wt%. The TEER test was performed before adding the CRL-8761-impregnated medium to the cell layer of the above well plate. CRL-8761 impregnated culture medium is placed inside the inner chamber, and some purified cell culture medium is added to the outer chamber. The cells are then grown. After a preset time interval, samples of the inner and outer lumens were collected, placed in separate tubes, and dried under vacuum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com