Transmitting screen-use light diffusing member

A light-diffusing and transmissive technology, applied in the direction of diffusing elements, optical elements, optics, etc., can solve problems such as the disappearance of concave-convex shapes on the surface of light-diffusing plates, the inability to obtain surface protection effects, and inability to obtain anti-reflection effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Hereinafter, the present invention is further described in detail by using examples, but the present invention is not limited to these

[0042] Example.

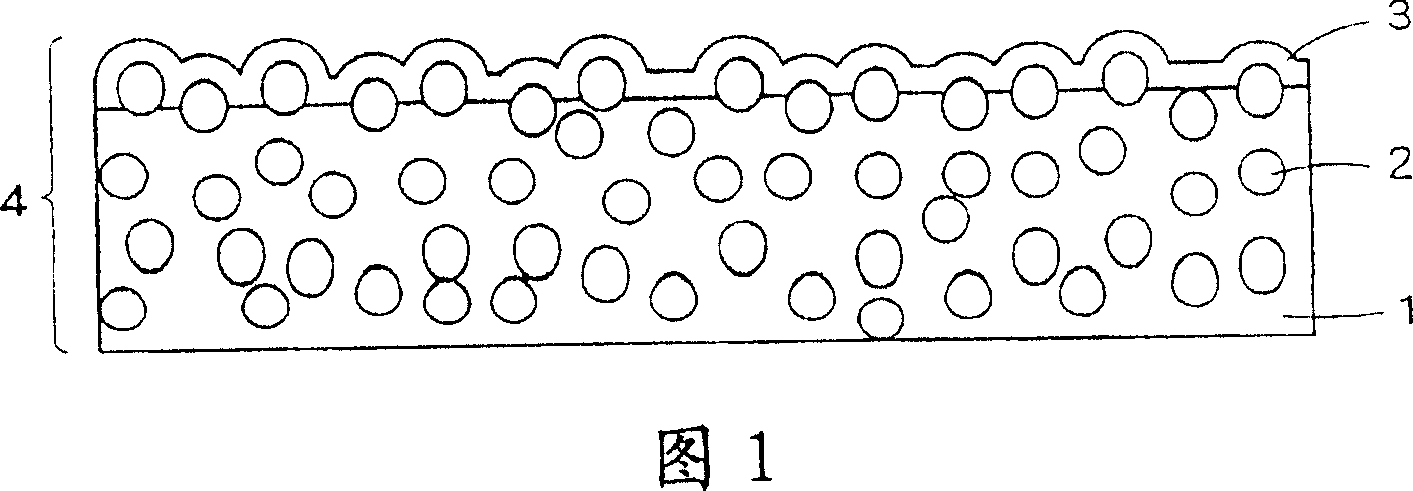

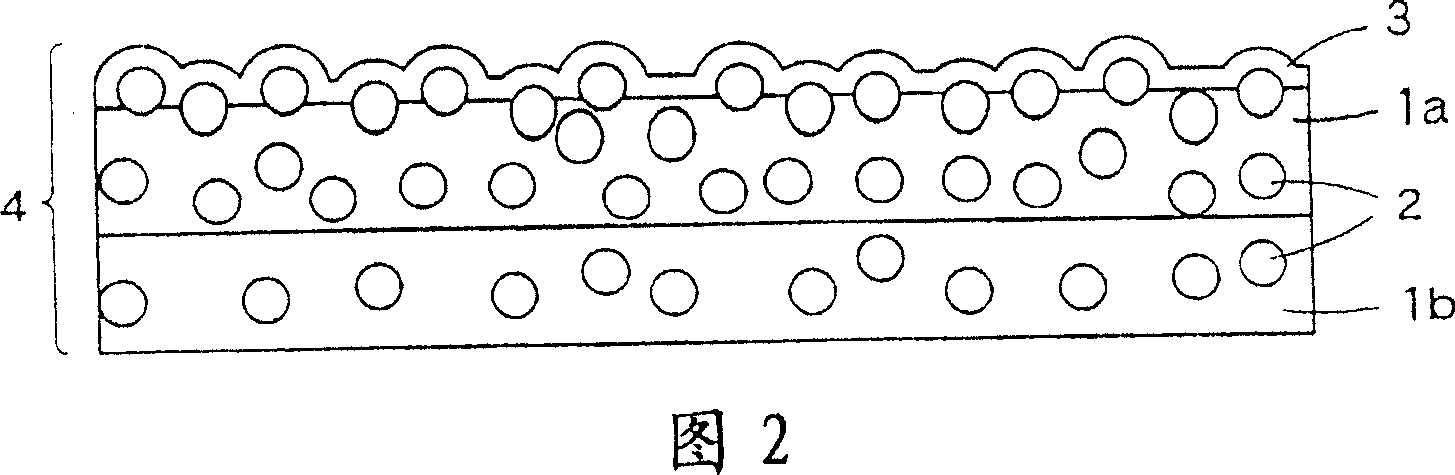

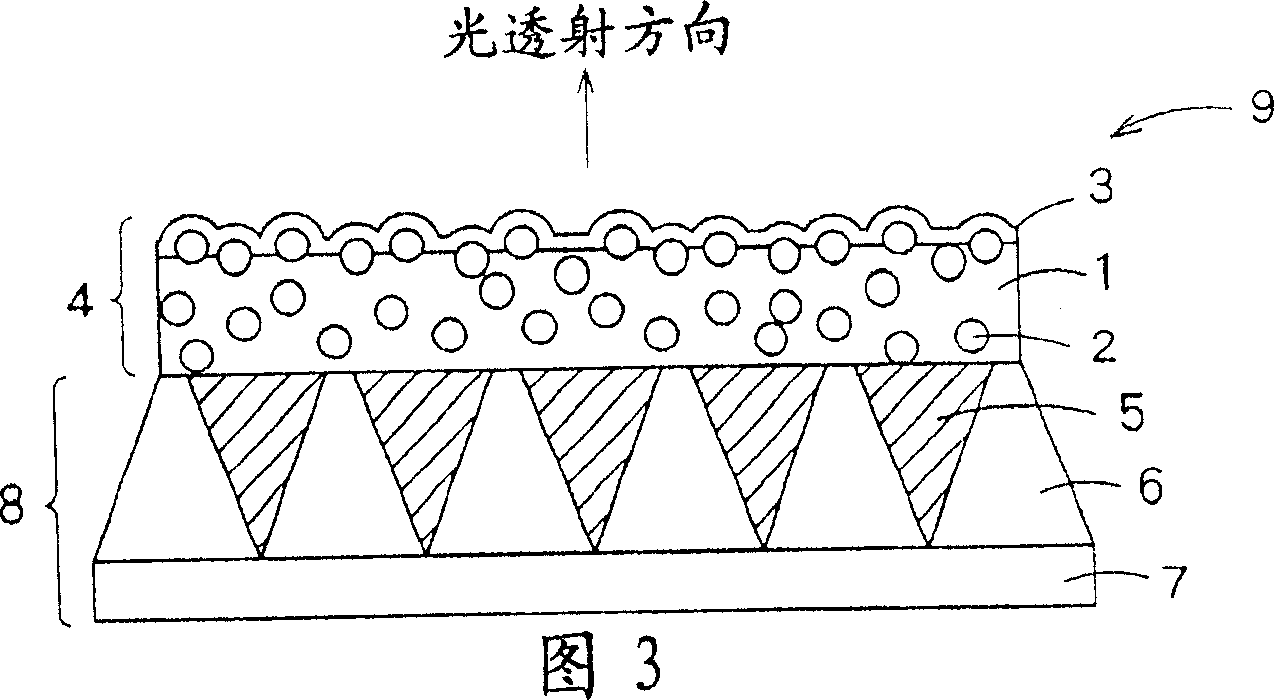

[0043] As the resin used for the base material of the light-diffusing member, MS (methacrylic acid-styrene copolymer) resin (refractive index: 1.53) was used. MS beads (refractive index: 1.49, average particle diameter: 10 μm) were used as microparticles used in the base material, and the addition amount of the microparticles to the base material was 15% by weight. These mixtures were extruded with a melt extruder to prepare a base material for a light-diffusing member.

[0044] Then, on the surface of the base material, an ultraviolet curable resin composition mainly composed of urethane acrylate is coated by dip coating, and ultraviolet rays are irradiated to cure the resin composition to form a hard coat layer on the base material to obtain light diffusing parts. The thickness of the hard coat layer is adjusted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com