Yihesu candy making process

A crispy and temperature-controlled technology, applied in confectionary, confectionary industry, food science, etc., can solve problems such as easy crushing, sticky teeth, lack of temperature and operation process index control, etc., to achieve crispy taste and sweet mouthfeel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preparation method of the Yihe crisp of the present invention will be described in further detail below in conjunction with specific examples.

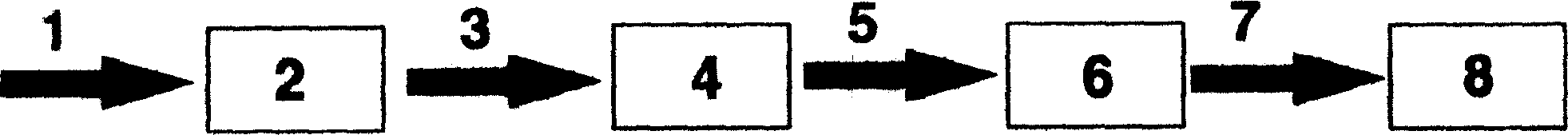

[0012] As shown in the figure, white sugar, maltose, maltose, soft white sugar and glucose are mixed in a certain proportion to form raw material (1). The raw material (1) is put into the container (2) and heated to make candy embryo. When heated to 140°C At -180°C, the candied carcass has turned into a yellow-brown material (3); the material (3) is fed into the container (4), and when the temperature drops to 70°C-90°C, the whitening is carried out in the container (4), and Always keep the temperature of the material at about 70°C-90°C until the yellow-brown material (3) is whitened into a white sugar tire (5); the white sugar tire (5) is input into the container (6), when the temperature Lower it to 70°C-90°C, and keep this temperature for wire drawing. The wire drawing method is carried out by two people back and forth i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com