No-deceleration obstacle acrossing mechanism

A climbing platform and transmission mechanism technology, applied in the field of non-deceleration climbing platform obstacle-crossing mechanism, can solve the problems of troublesome assembly, no deceleration, poor adjustability, etc., and achieve the effect of good effect, fast speed and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

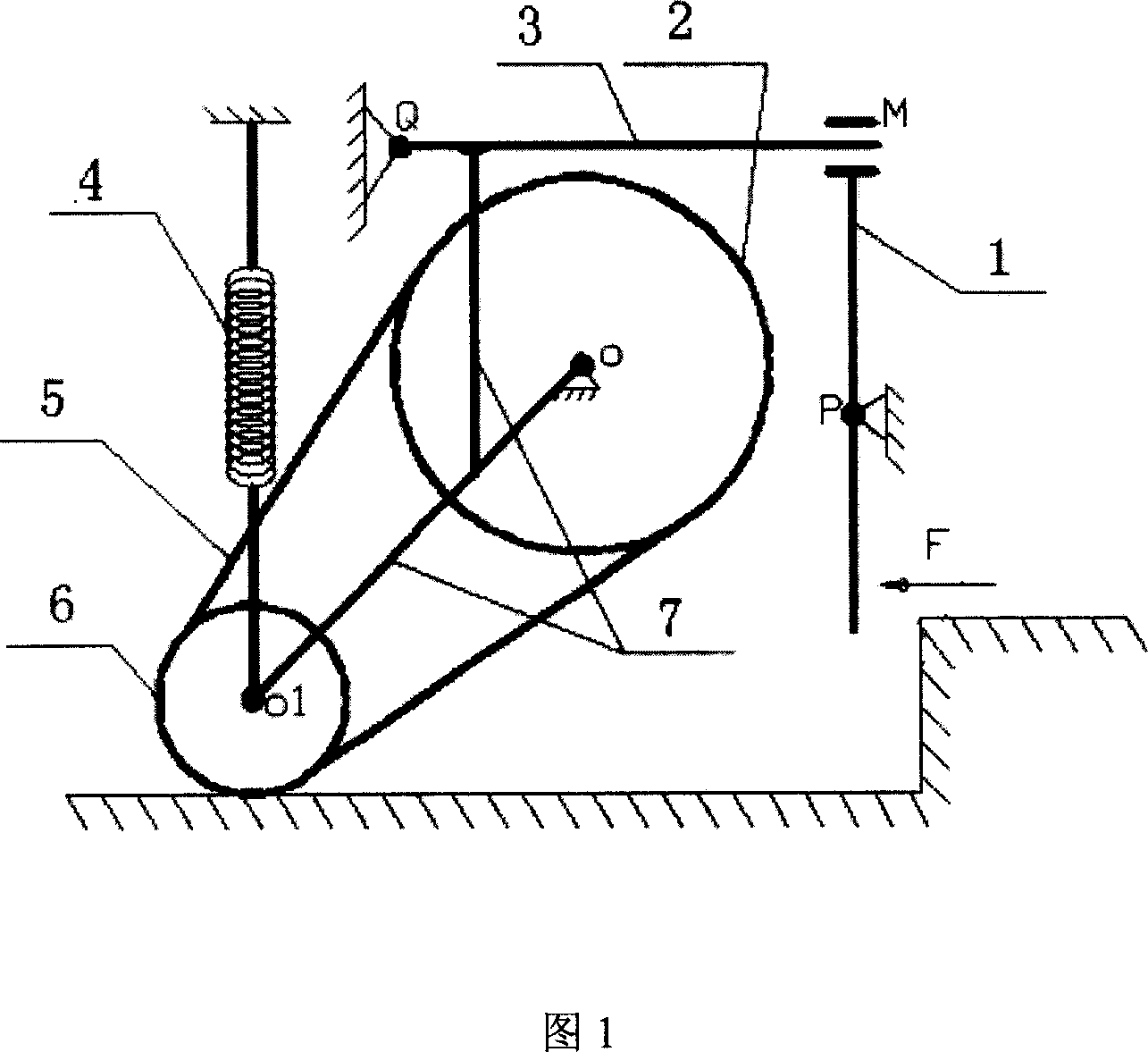

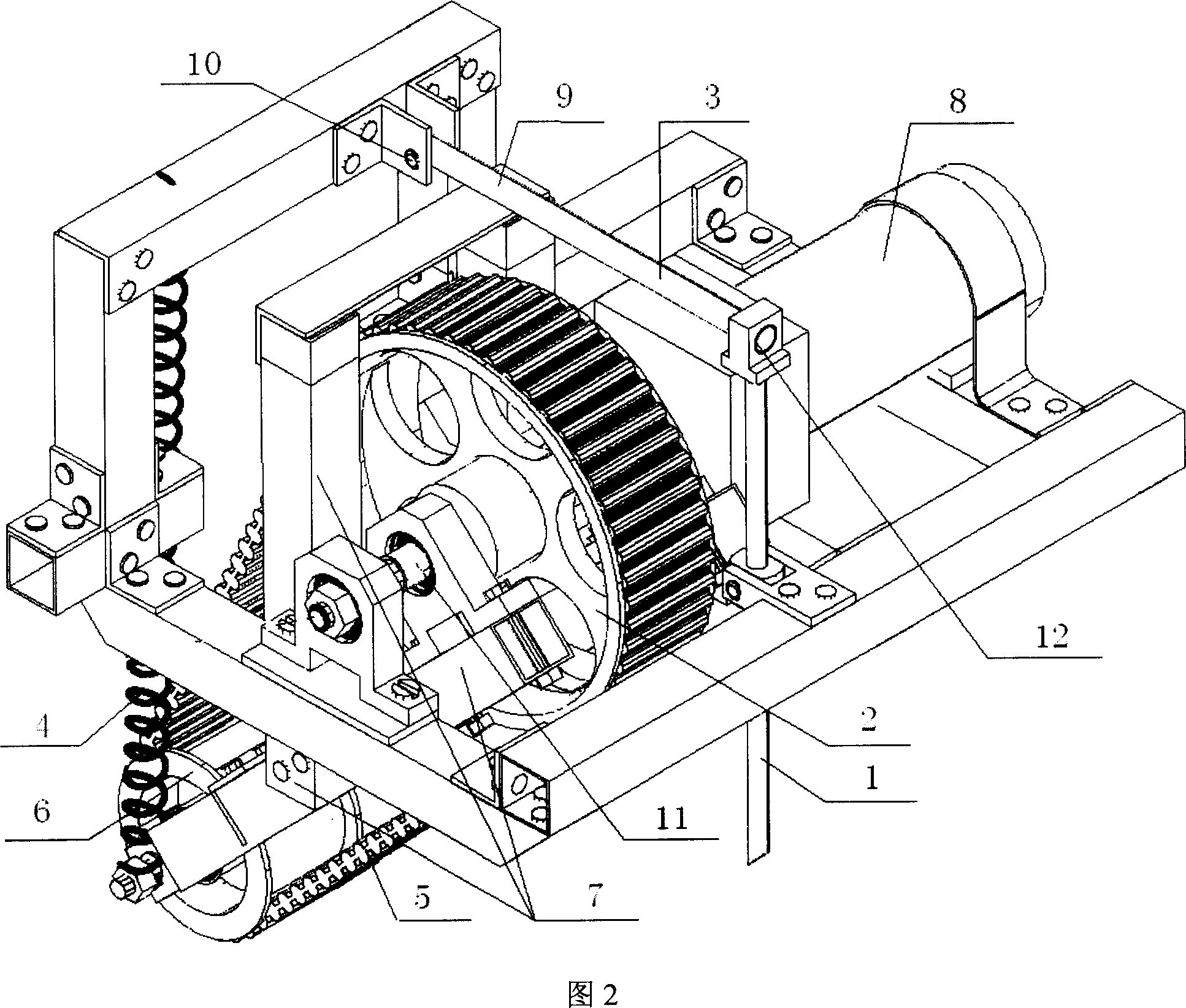

[0014] In conjunction with accompanying drawing, concrete structure of the present invention is described below:

[0015] The invention consists of four parts: a car body chassis support, a transmission mechanism, a secondary lever trigger mechanism, and a driven wheel lifting mechanism. The transmission mechanism, the secondary lever trigger mechanism and the driven wheel lifting mechanism are fixed on the vehicle body chassis support. The car body chassis support includes a metal support frame, a drive motor 8, and a bearing seat. The metal frame supports the entire mechanism. The transmission mechanism and the driven wheel lifting mechanism are supported by the bearing seat; the transmission mechanism is composed of a transmission belt, a driving wheel 2 and a driven wheel 6. The transmission belt The degree of tightness can be mediated through the screws on the expansion mechanism; the driving motor 8 is connected to the driving wheel 2, and the transmission mechanism is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com