Gas-liquid mixed discharge process and apparatus for degrading organic pollutant in water

A technology of organic pollutants and gas-liquid mixing, applied in the field of ion technology in the field of environmental pollution control, can solve the problems of small contact area, short residence time, fast airflow velocity, etc., to improve degradation efficiency, high utilization rate, and convenient production. Effect

Inactive Publication Date: 2007-03-21

CHINA UNIV OF PETROLEUM (EAST CHINA)

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the airflow velocity is fast, the bubbles are large, the contact area between ozone and organic

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

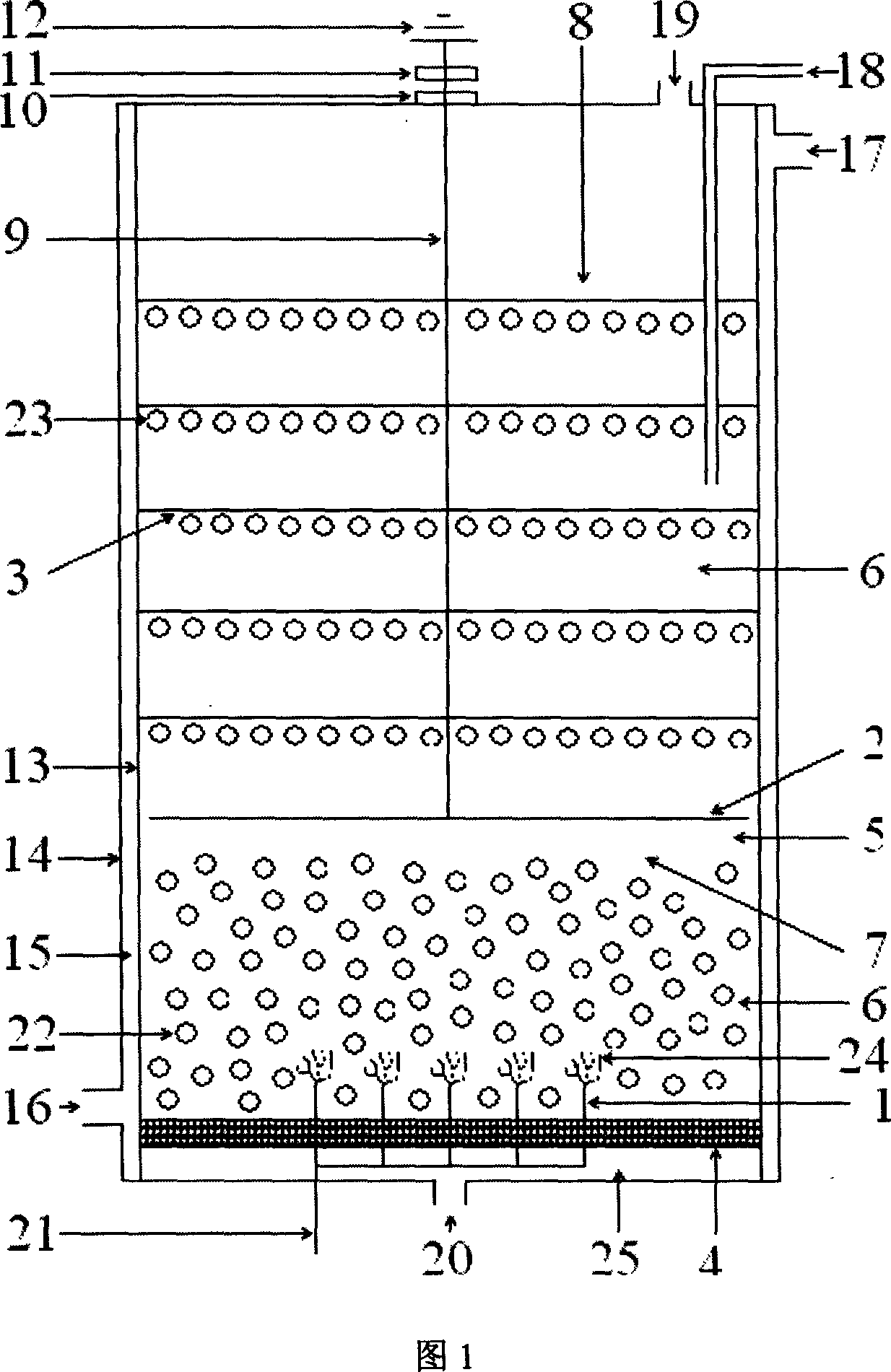

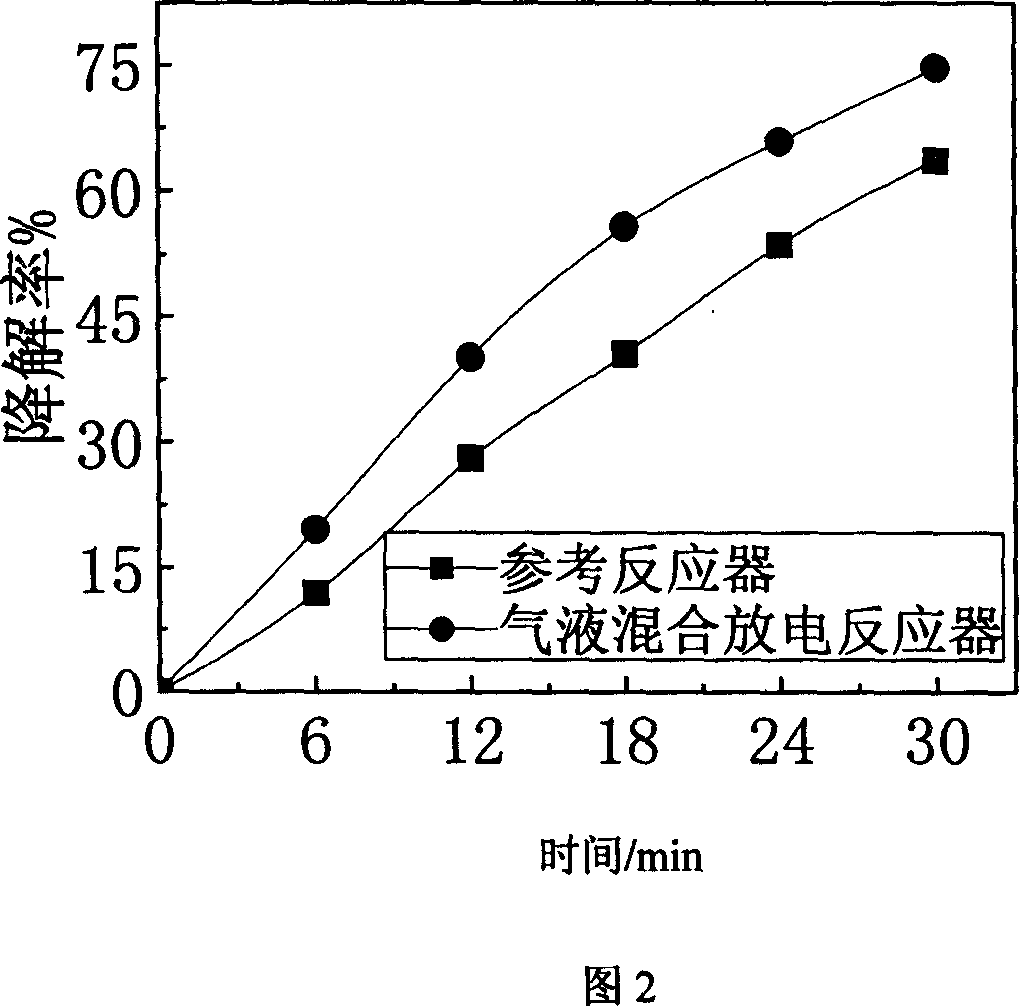

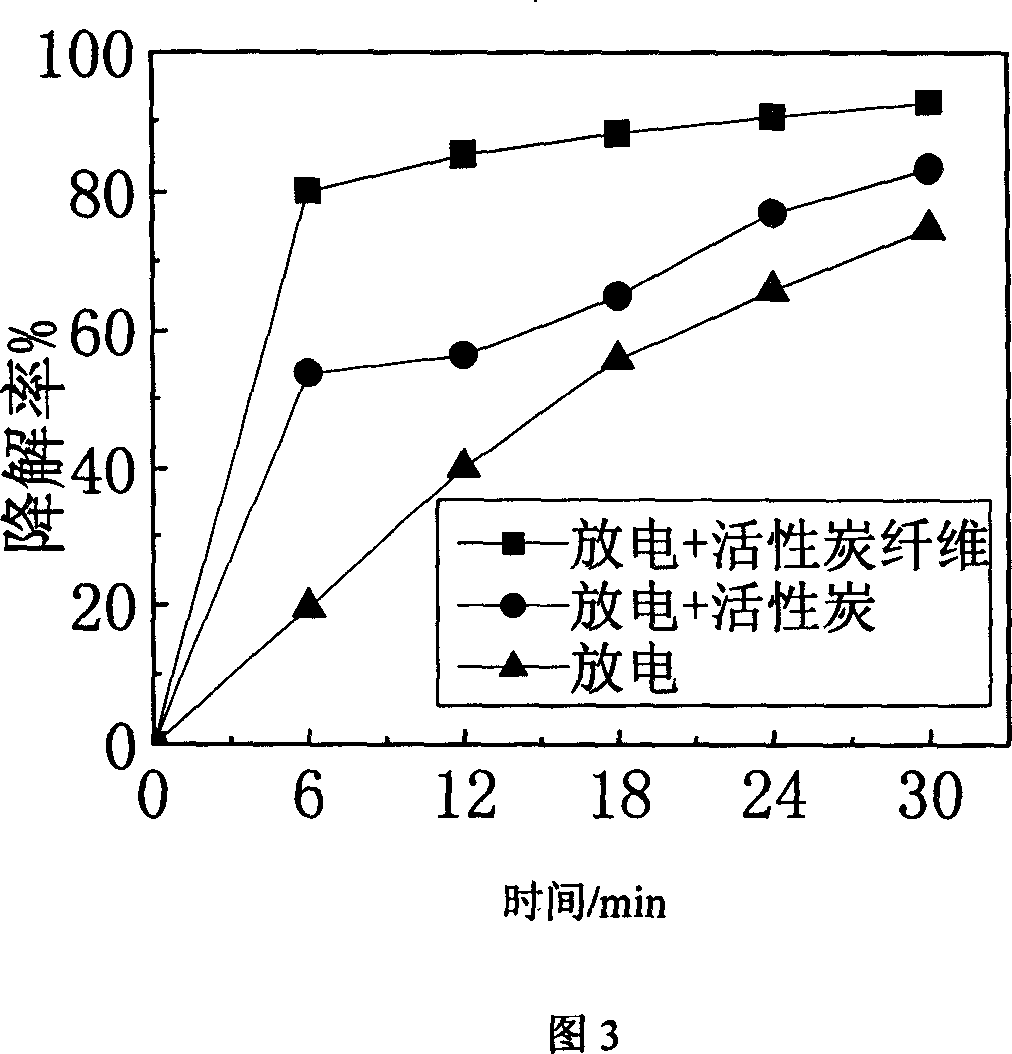

The present invention belongs to the application of low temperature plasma technology in the field of controlling environmental pollution, and is especially high voltage pulse discharge apparatus and process to generate high chemically active particle degrading organic pollutant in water. The technological scheme includes using sand core to make the solution distributed homogeneously in the lower layer inside the reactor, applying high voltage pulse across The high voltage electrode in the liquid phase and the earth electrode in the gas phase, acting the liquid phase generated low temperature plasma and the gas phase generated ozone directly on the organic pollutant under the action of high strength electric field, using the baffling metal net in the solution to raise ozone utilization rate, adding active carbon fiber and ferrous ion into solution to raise the organic pollutant treating effect.

Description

technical field [0001] The invention belongs to the application of low-temperature plasma technology in the field of environmental pollution control, and relates to a method and a device for degrading organic pollutants in water by using high-activity chemical particles generated by high-voltage pulse discharge. Background technique [0002] At present, the pharmaceutical, printing and dyeing, chemical, petroleum and other industries have produced a large amount of industrial wastewater. This type of wastewater has a large discharge volume, complex water quality, high content of toxic and harmful pollutants, and a wide distribution range, which poses new challenges to traditional water treatment processes. In the past 30 years, some new water treatment technologies have emerged for these refractory wastewater. Among them, high-voltage pulse discharge has attracted widespread attention due to the diversity of energy release in the electron transfer process and its application ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F1/46C02F1/48

Inventor 郑经堂张延宗陈宏刚张玉贞赵玉翠刘颖曲险峰

Owner CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com