Bottom driving whole hydraulic plate-inserting machine

A fully hydraulic, plug-in machine technology, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of low plug-in efficiency, inability to achieve, intubation efficiency cannot be improved, etc., to improve intubation efficiency, improve The effect of intubation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

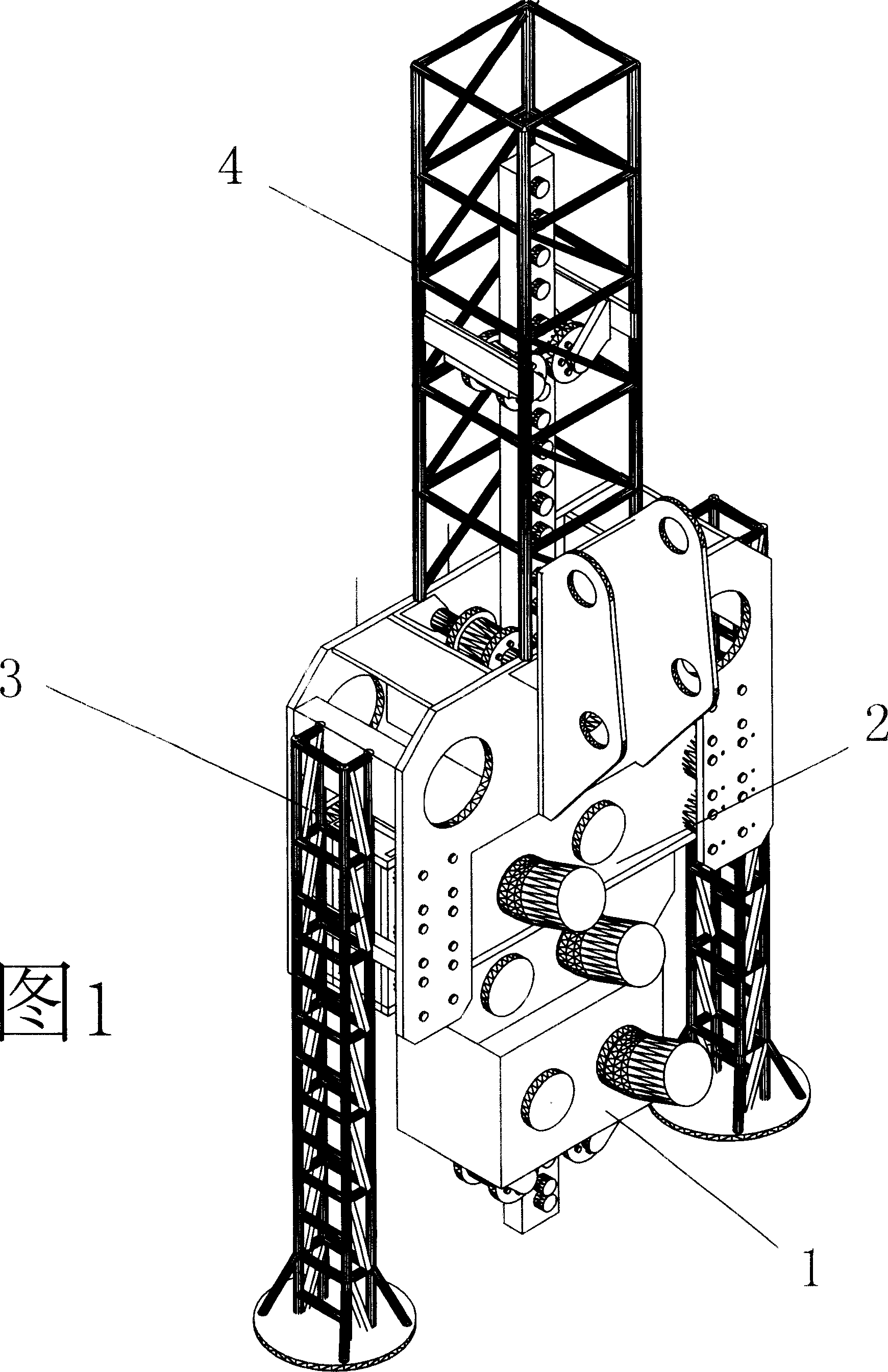

[0020] The present invention relates to a bottom-drive full-hydraulic slotting machine, referring to FIG. 1 , which includes a static force generating mechanism 1 , a vibrating box 2 , a vibration damping device 3 , a truss mechanism 4 , and a hydraulic-electric interface and a control part 5 .

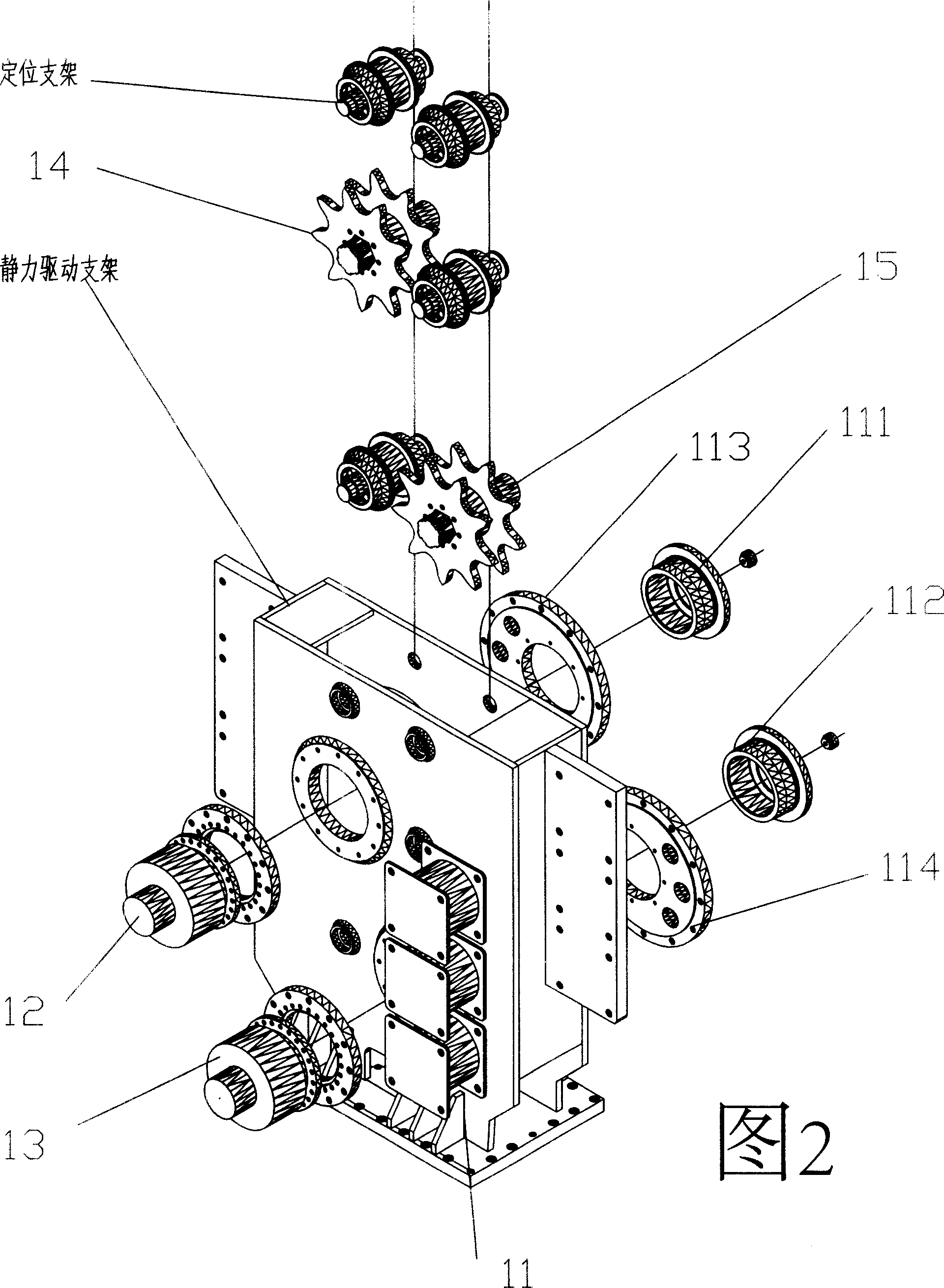

[0021] Fig. 2 has shown the structural stereogram of static force generating mechanism 1, with reference to Fig. 2, static force generating mechanism 1 comprises shell 11, rotary motor 12, planetary reduction device 13, double sprocket shaft 14 and transmission gear shaft 15; Wherein, shell 11 is provided with a bearing seat 111 and a bearing seat 112, and the bottom is provided with a connecting part 113 connected to the vibration box 2. Both sides are provided with a connecting plate 114 connected to the vibration damping device 3. The double chain gear shaft 14 is mounted on the bearing seat through the bearing pair 141. 111, one end of which is connected to the lifting rotary motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com