Chain and method for blanking hole in chain plate

A processing method and chain technology, which is applied in the field of chains, can solve problems such as cracks, fatigue fracture of chain plates, and inability to obtain strength, and achieve the effects of improving fatigue strength, increasing fatigue strength, improving dimensional accuracy and surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

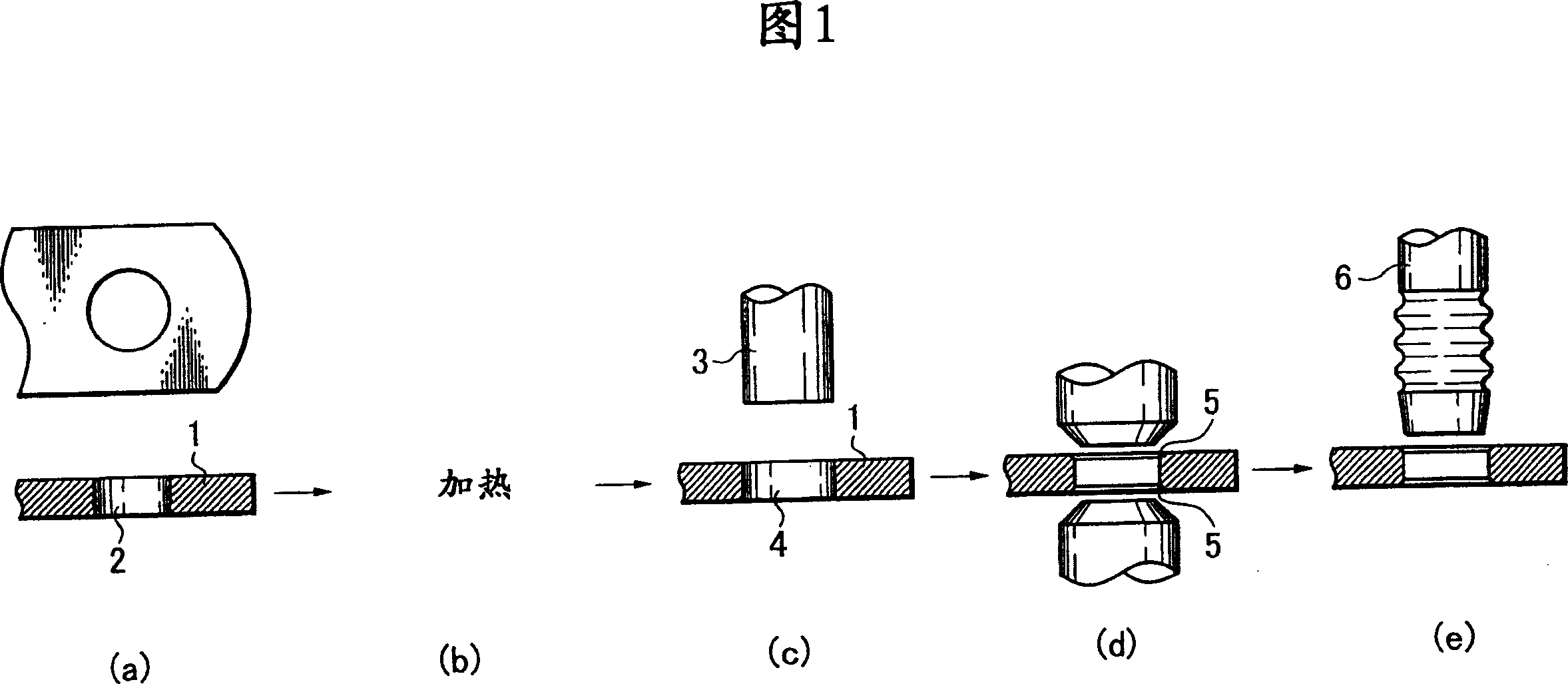

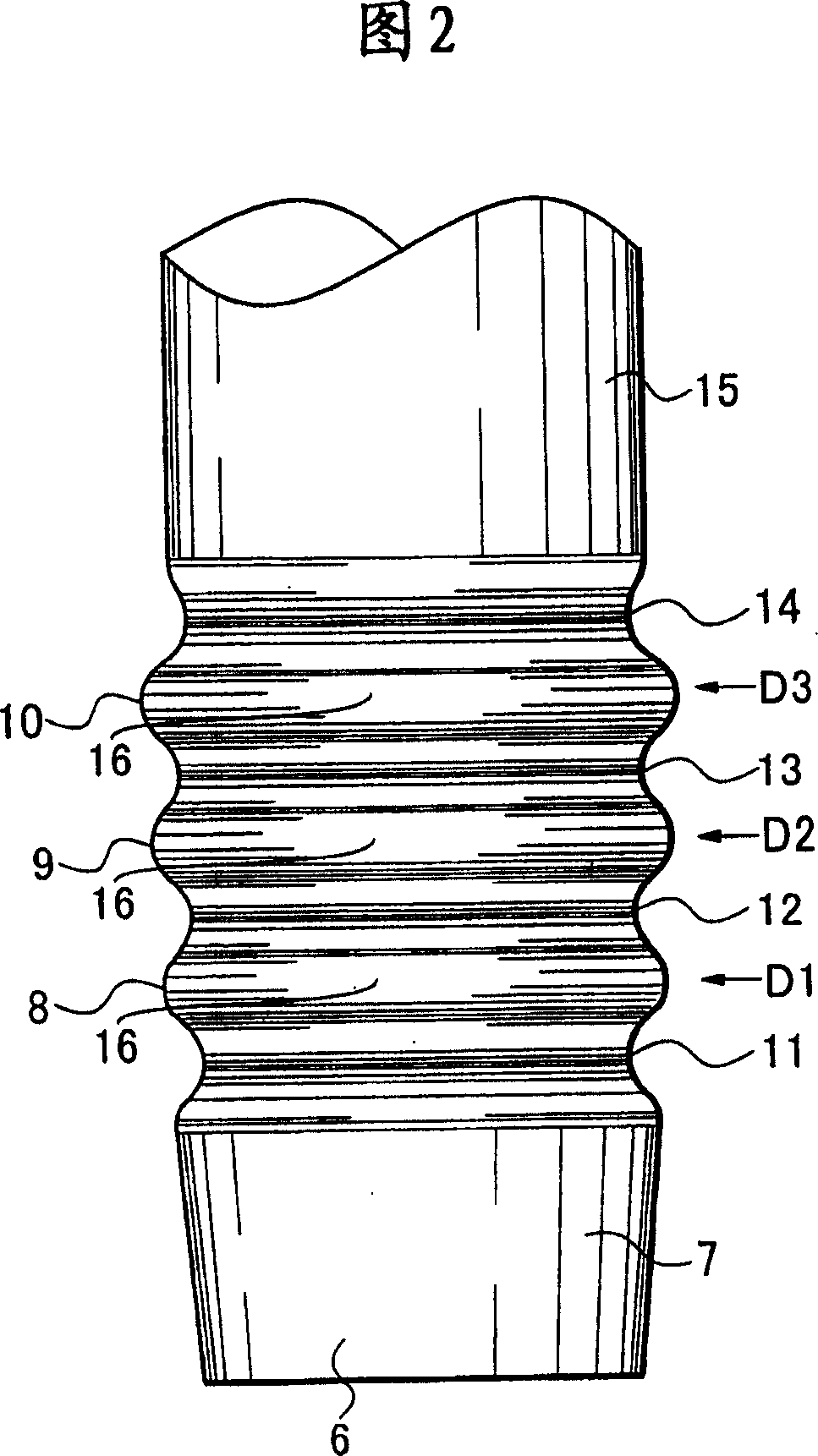

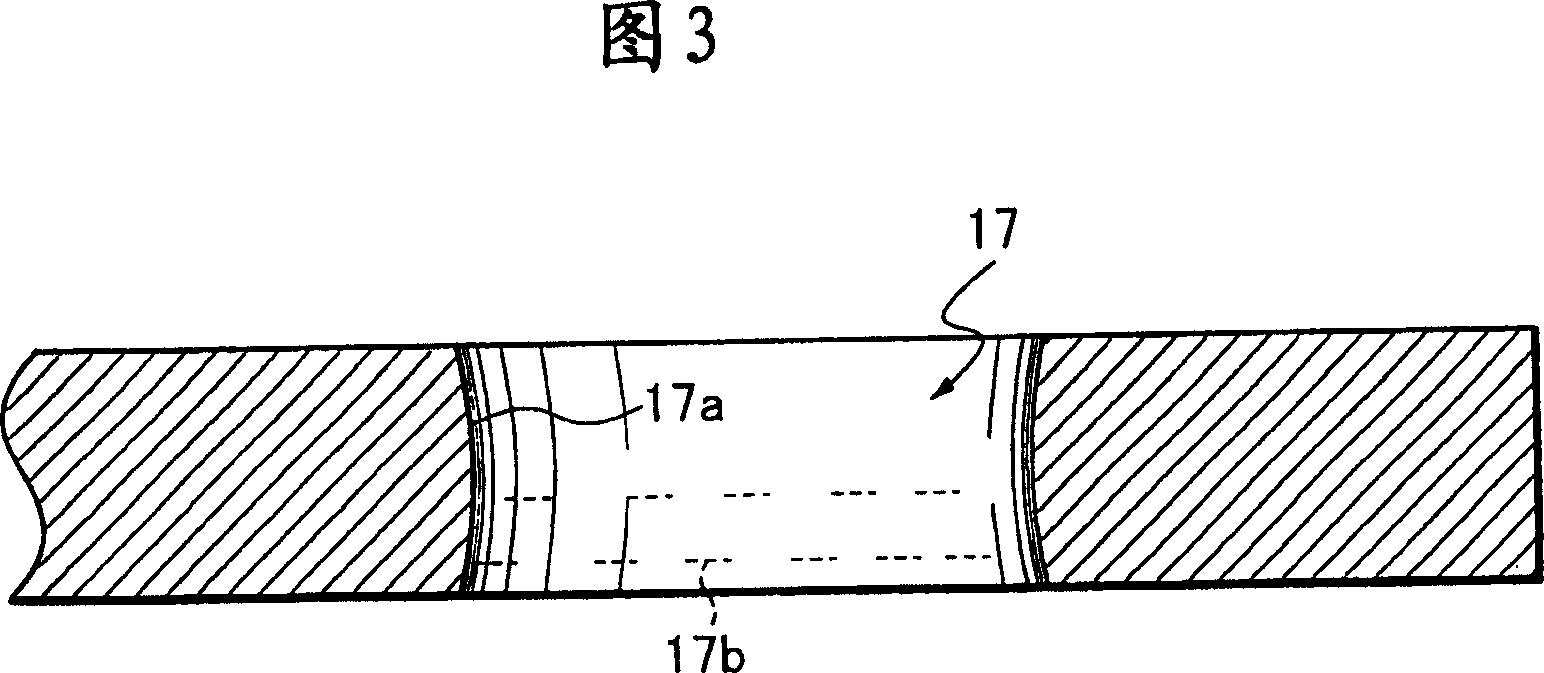

[0032] FIG. 1 shows the processing steps of the plate according to the present invention. First, (a) the plate 1 is punched and punched. Pre-drilled holes 2 are formed at both ends of the substantially elliptical link plate 1 . The pin is inserted into this pre-drilled hole 2 in the case of the outer plate 1 and into the bushing in the case of the inner plate. Then, (b) heat-treat the punched and punched plate to provide strength for functioning as a chain member. During heat treatment, the quenching temperature and tempering temperature are slightly different depending on the material of the plate and the application of the chain.

[0033] (c) Next, gear shaving is performed on the pre-drilled hole 2 of the heat-treated plate 1 . Here, the shaving punch 3 is inserted into the pre-drilled hole 2 , and the trumpet-shaped pre-drilled hole 2 after punching and punching is processed for shaving. Straight hole 4 is obtained by shaving. (d) Next, chamfering is performed on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com