Application of silicone rubber in electromagnetic coil package and packing method

A technology of electromagnetic coil and packaging method, applied in the direction of coil, coil manufacturing, circuit, etc., can solve the problem of inappropriate electromagnetic coil, and achieve the effect of easy implementation, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

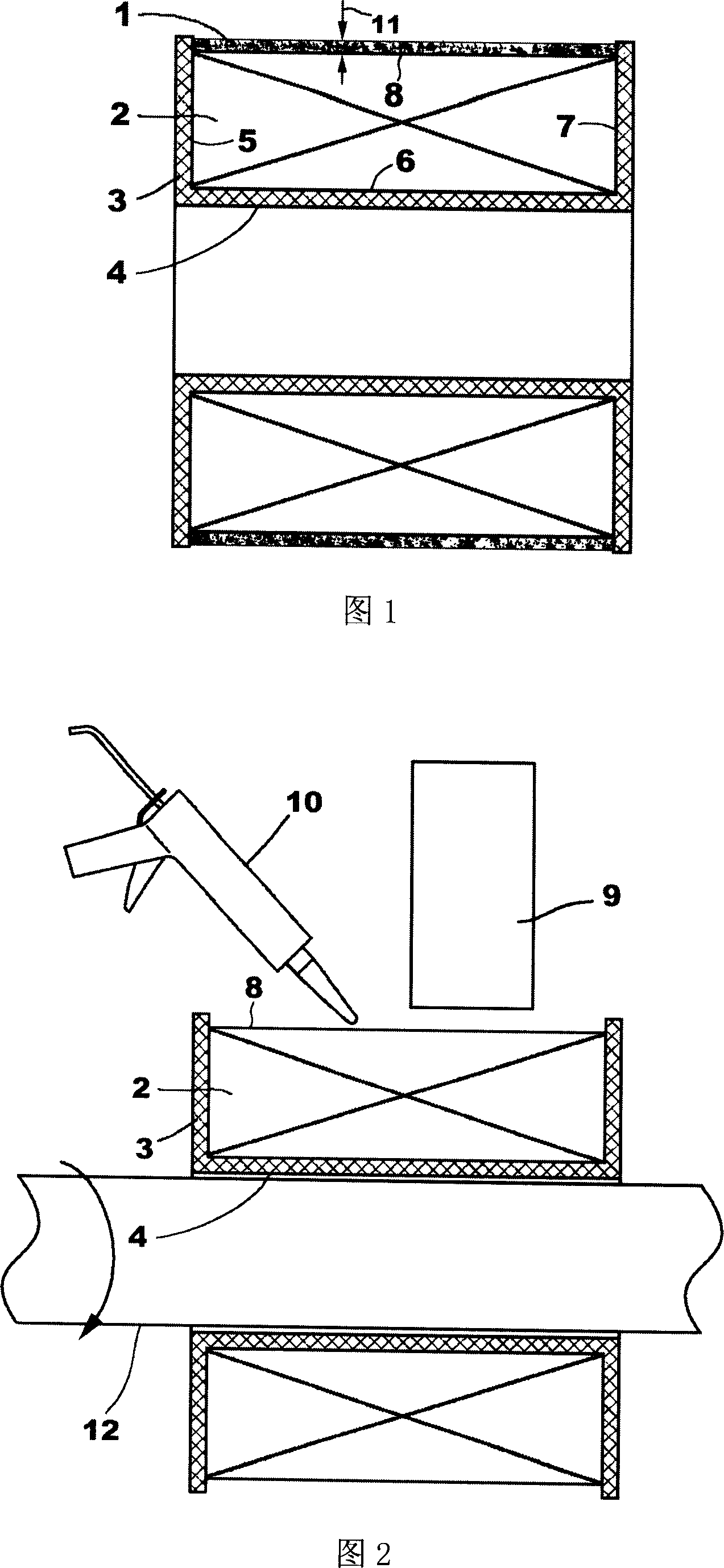

[0021] As shown in Fig. 1, the application of the silicone glue of the present invention in electromagnetic coil packaging is to wind the enameled wire winding 2 on the I-shaped coil frame 3 and encapsulate the silicone glue sealing outer layer 1 to form an electromagnetic coil.

[0022] The silicone glue can be 587, 596, 598, 5699 or 207.

[0023] The specific method is: when making an electromagnetic coil, an I-shaped coil bobbin 3 is required, which has a first surface 6, a second surface 5 and a third surface 7 to carry the enameled wire winding 2; Hole 4 is used to install the magnetizer and fix it on the winding machine shaft when winding the enameled wire.

[0024] After the enameled wire 2 is wound on the bobbin 3, since the first surface 6, the second surface 5 and the third surface 7 of the bobbin 3 are all sealed, external oil, gas, water, etc. cannot enter the enameled wire winding 2, these three surfaces can be sealed. Then apply silicone glue on the outer surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap