Coating apparatus, organic material thin film forming method and organic el panel manufacturing apparatus

A coating device and organic material technology, applied to the surface coating liquid device, printing device, lighting device, etc., can solve the problems of violating space saving and high cost, and achieve the effect of shortening the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

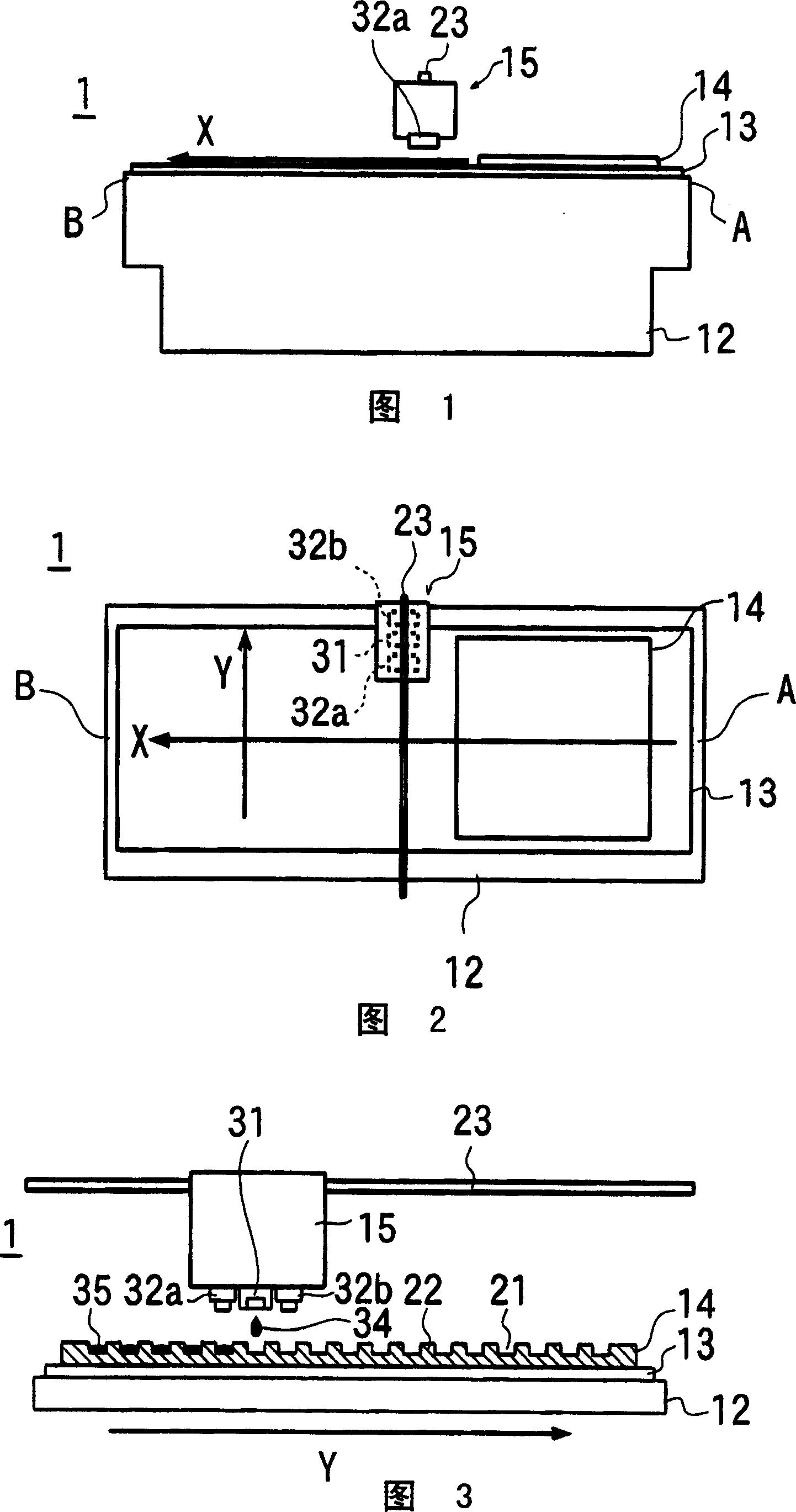

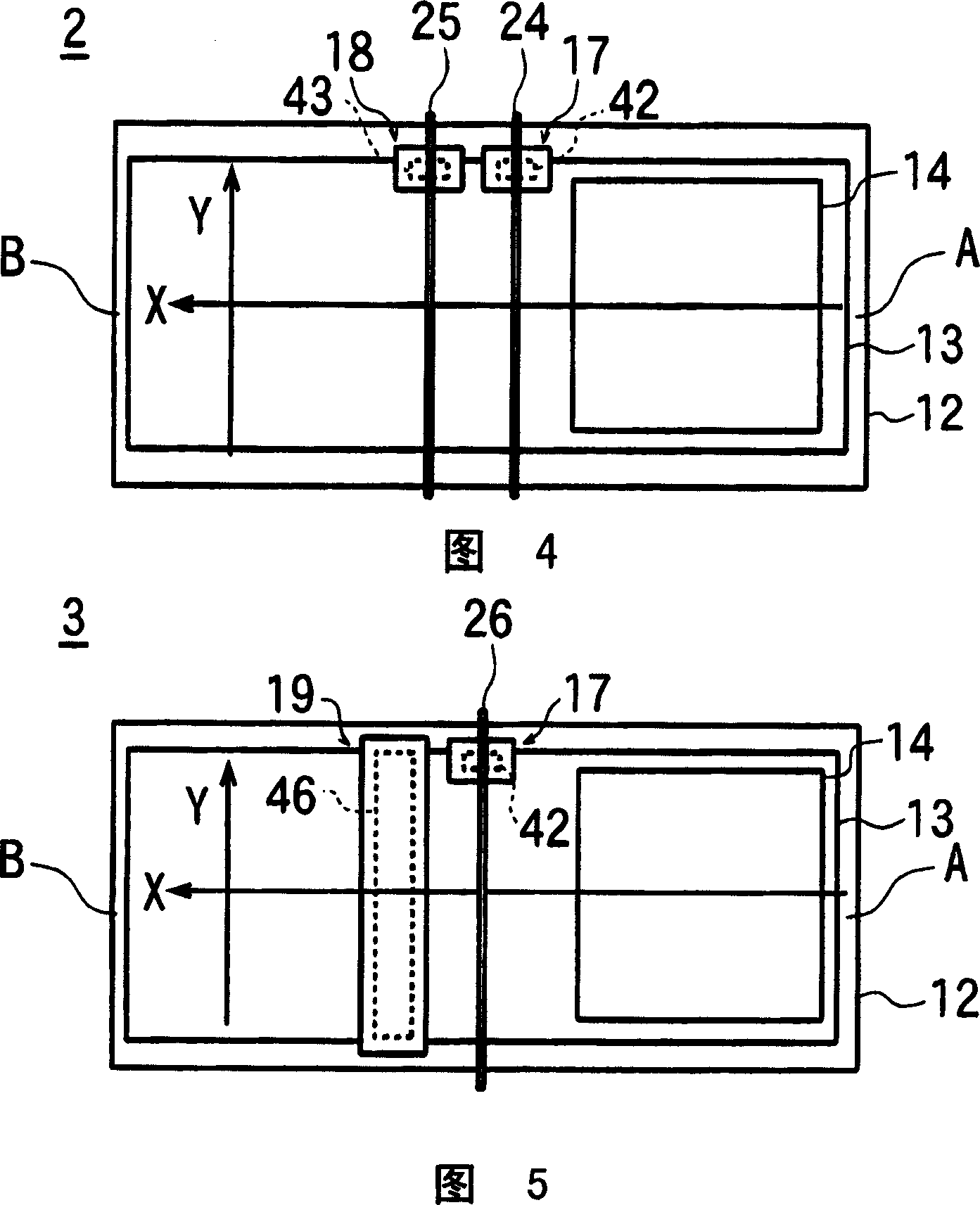

[0047] Reference numeral 1 in FIG. 1 denotes a coating device of a first example of the present invention.

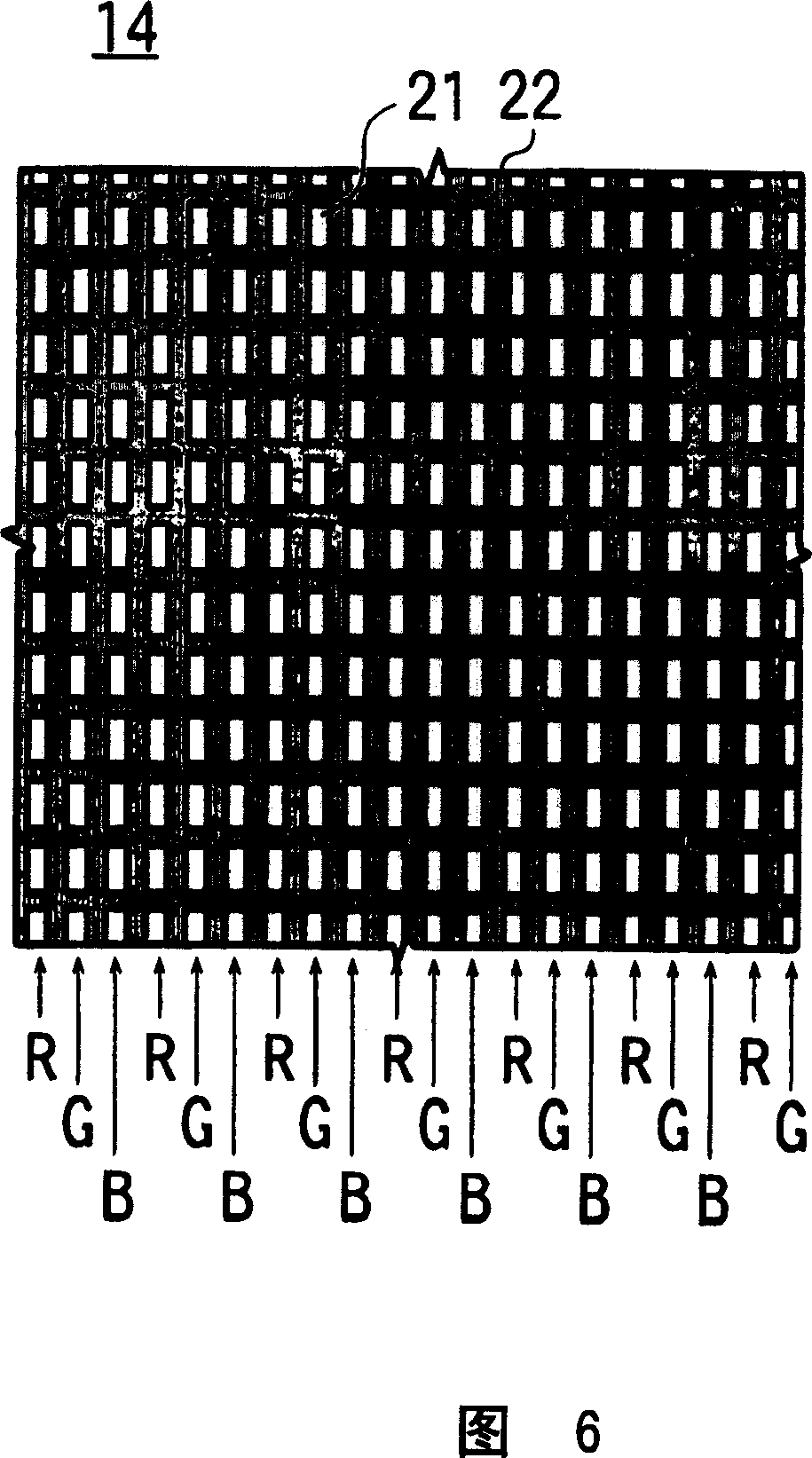

[0048] The coating device 1 has a coating station 12 . A substrate conveyance mechanism 13 is provided on the coating stage 12, and by the operation of the substrate conveyance mechanism 13, the object 14 to be coated on the coating stage 12 can be moved along the longitudinal direction of the coating stage 12 from The movement source A side of the coating table 12 moves toward the movement destination B. As shown in FIG. That is, in the movement of the object to be coated 14, the movement source A is on the upstream side, and the movement destination B is on the downstream side.

[0049] A head moving mechanism 23 is arranged above the coating table 12 , and a movable head 15 is attached to the head moving mechanism 23 . By the operation of the head moving mechanism 23 , the head 15 can reciprocate in a direction substantially perpendicular to the direction of moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com