Heat radiating system and method

A technology of a heat dissipation system and a heat dissipation method, which is applied in cooling/ventilation/heating renovation, instrument cooling, instrument and other directions, can solve the problems of reliability of heat dissipation effect and maintenance of heat dissipation fins 12, etc., to prevent accumulation in heat sources, The effect of reducing dust and keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The heat dissipation system and the heat dissipation method thereof according to preferred embodiments of the present invention will be described below with reference to related drawings.

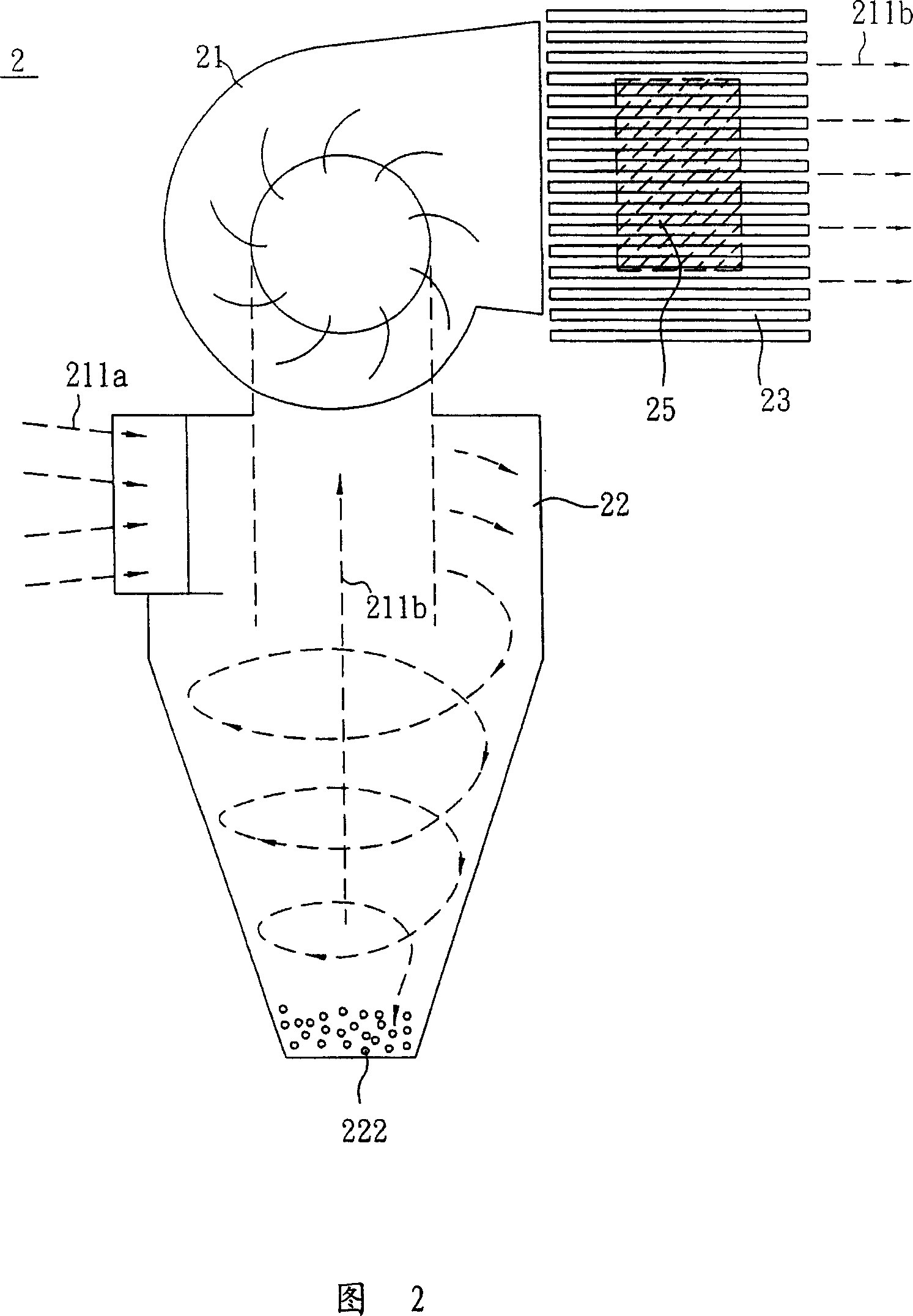

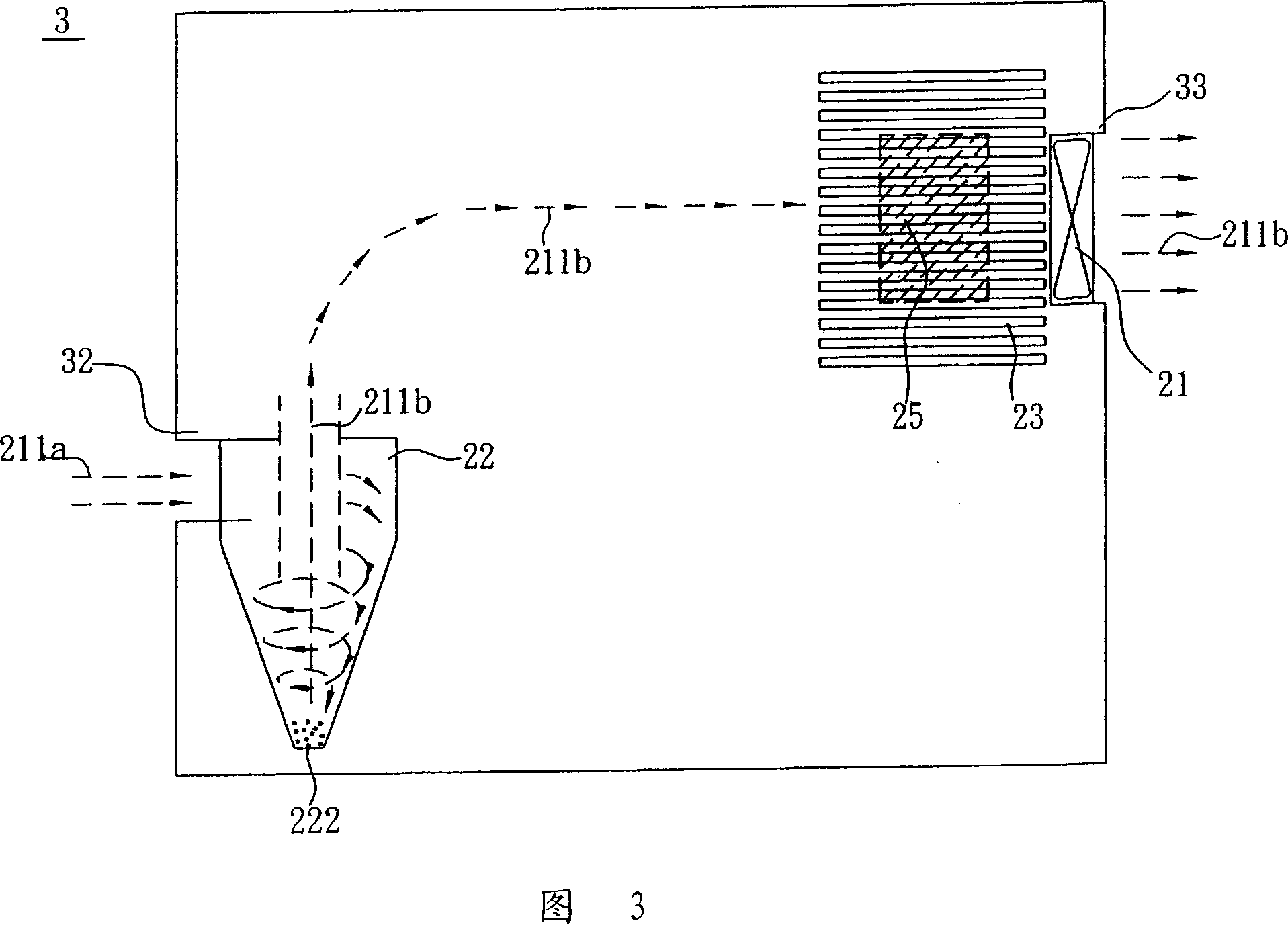

[0019] As shown in FIG. 2 , it is a schematic diagram of a heat dissipation system according to a preferred embodiment of the present invention. The heat dissipation system 2 is applied to a heat source 25 , and the heat dissipation system 2 includes a fan 21 , a dust separator 22 and a heat dissipation fin 23 .

[0020] The fan 21 is an axial fan or a centrifugal fan. When the fan 21 rotates, air is collected from the outside of the heat dissipation system 2 to generate an airflow 211a, and the airflow 211a flows into the dust separation device 22 immediately. Under the action of centrifugal force and gravity, The dust 222 entrained in the airflow 211a will be settled to the bottom of the dust separating device 22, while the separated clean airflow 211b directly enters the fan 21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com