System for adhesive segment dispensing

A technology for dispensing equipment, adhesives, applied in the direction of adhesives, pile separation, layered products, etc., which can solve problems such as difficulty in handling, hindering the feeding of carrier tapes, and clumsiness of consuming carrier release tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

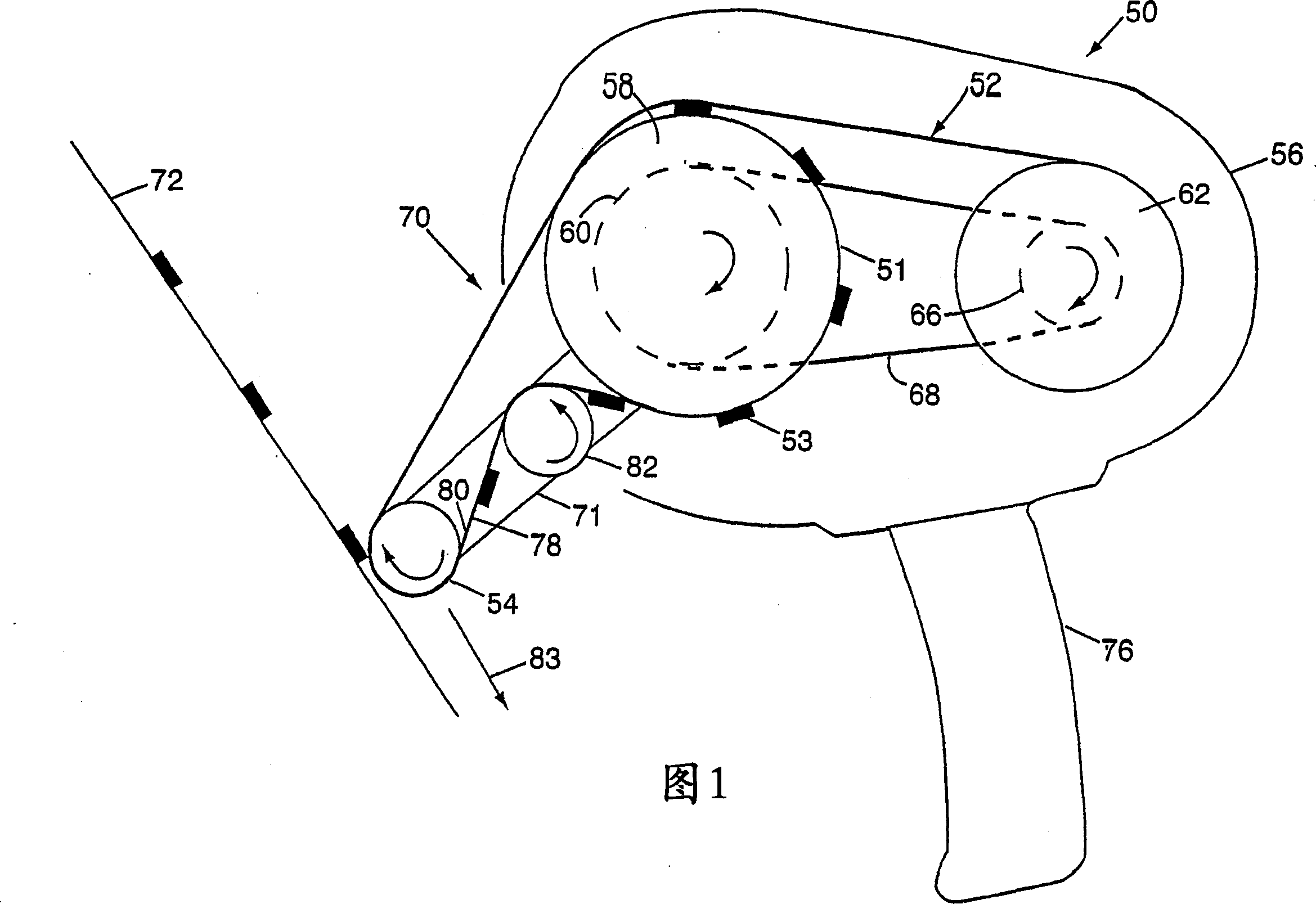

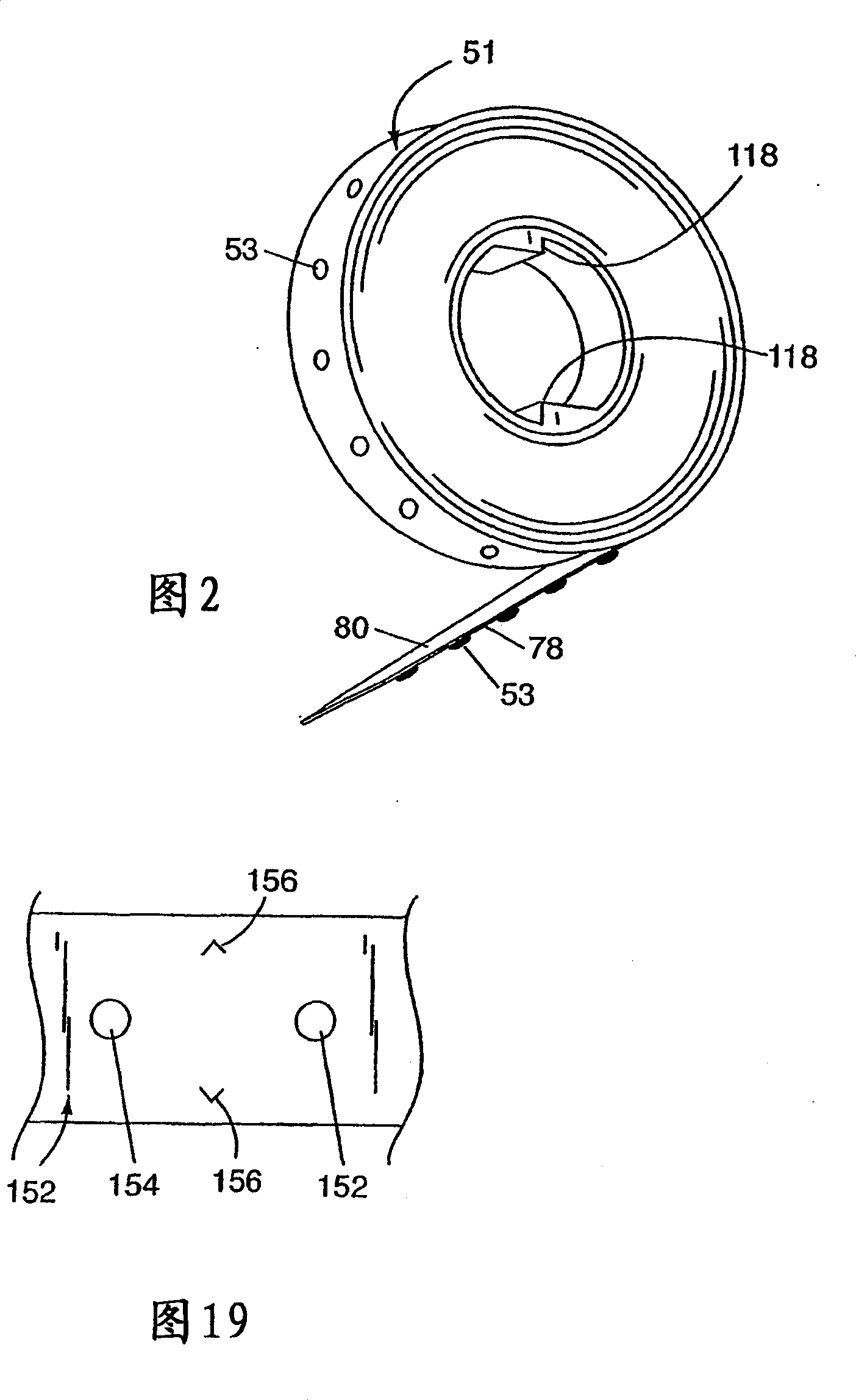

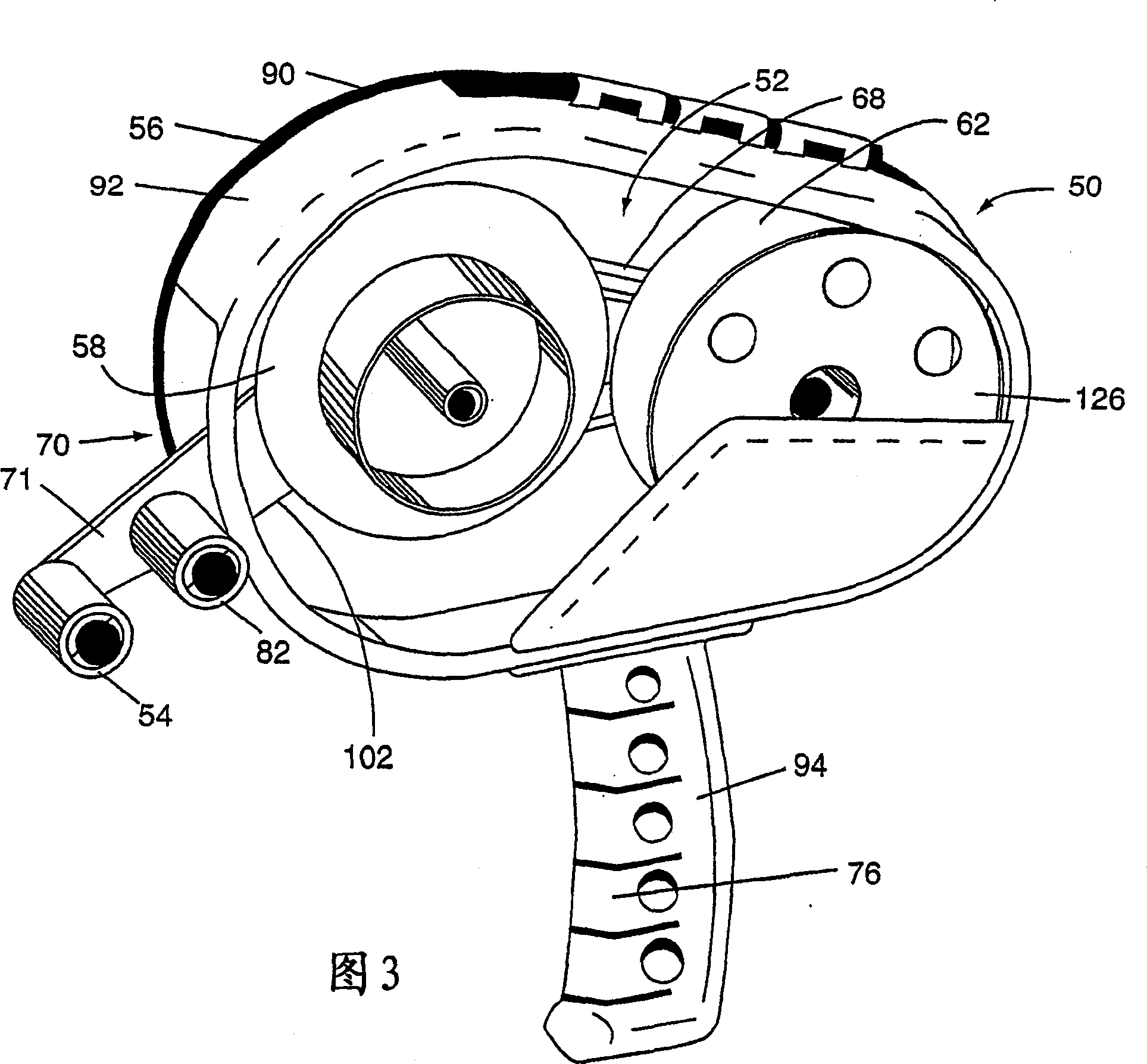

[0066] The preferred embodiment of the adhesive segment applicator apparatus 50 of the present invention is shown in figure 1 , make the adhesive segment-loaded carrier release 51 tape including the plurality of adhesive segments 53 used therein indicated at figure 2 middle.

[0067] First refer to figure 1 , the adhesive segment applicator apparatus 50 includes a carrier tape dispensing system, indicated generally at 52 , an adhesive dispensing wheel 54 , and an applicator housing 56 . The carrier tape dispensing system 52 includes a supply shaft 58 rotatably mounted within the housing 56 of the adhesive segment applicator apparatus 50 by any means known to those skilled in the art. Alternatively, the supply shaft 58 may be removably and rotatably mounted with the housing 56 so that supply shafts of different sizes may be interchanged with the supply shaft 58 .

[0068] The supply shaft 58 is configured to securely support the adhesive segment-loaded carrier release tape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com