Belt pulley driven inclined vertical trephine and its using method

A pulley and trephine technology, used in boring/drilling, drilling/drilling equipment, components of boring machines/drilling machines, etc., can solve the problems of time-consuming and difficult processing, and achieve compact structure and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

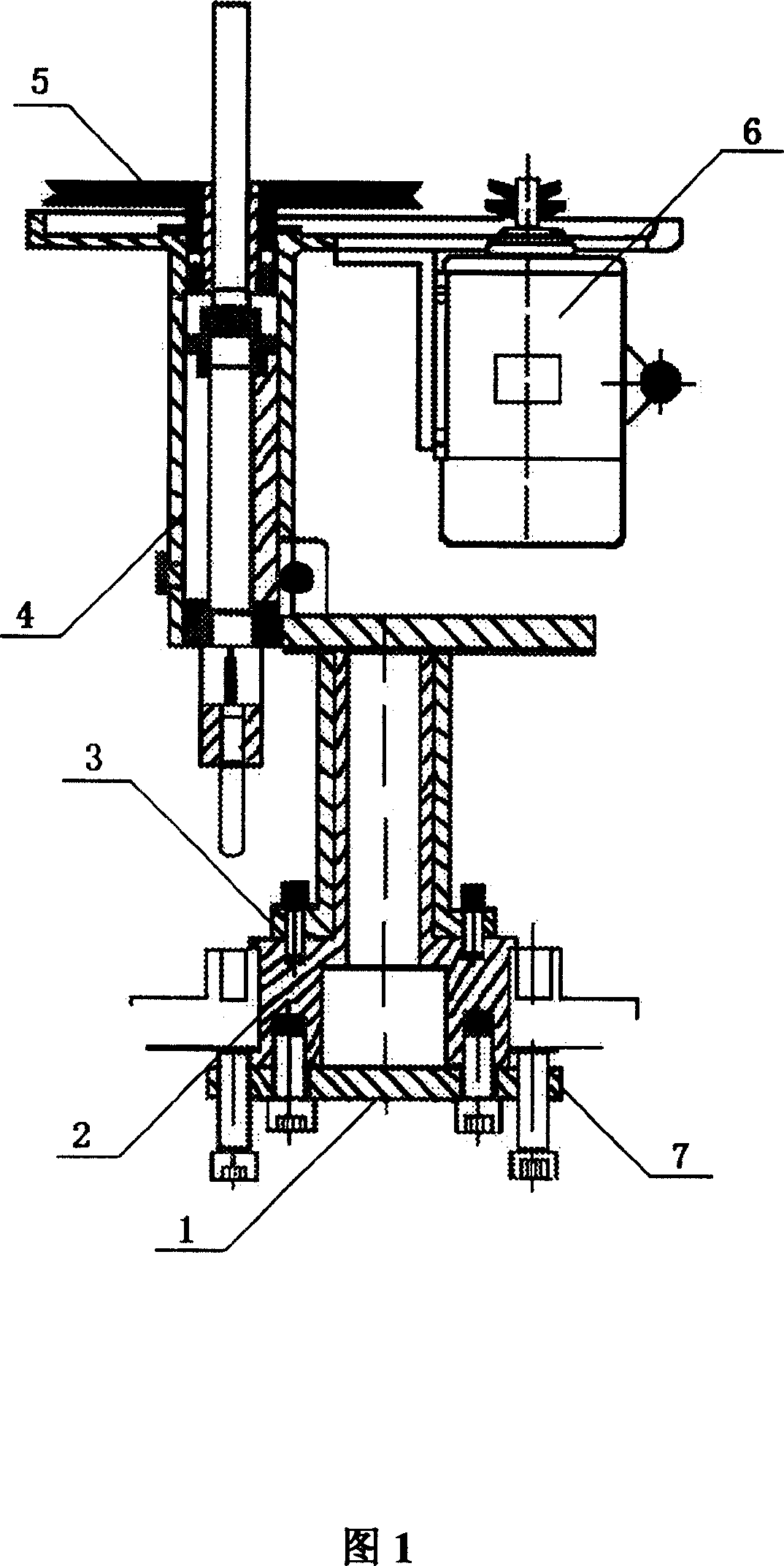

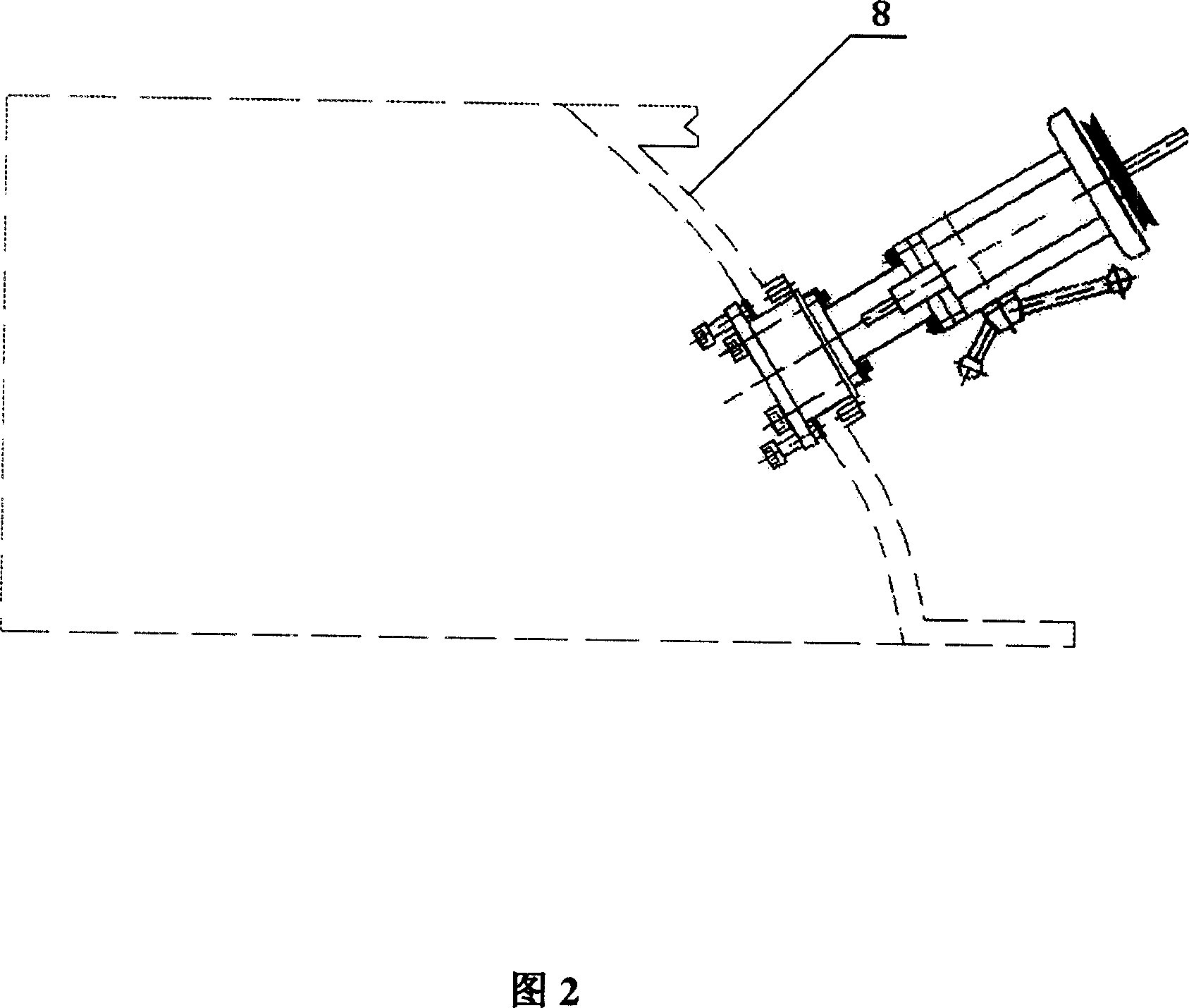

[0010] Further describe technical scheme of the present invention below in conjunction with accompanying drawing: pulley transmission type oblique vertical trephine, it comprises base plate 1, base 2, swivel seat 3, bit case 4, belt pulley 5, motor 6, spacer 7, wherein Motor 6 is installed among the bit box 4, and belt pulley 5 is placed on the bit box 4, is suspended state. When drilling, put the base 2 that matches the shaft hole of the outer water distribution ring into the shaft hole of the outer water distribution ring, and fix the base 2, the bottom plate 1 and the outer ring with the bolt top copper gasket 7, and turn the rotating base 3 to realize the position indexing of the hole, and adjust the diameter position of the hole by moving the drill box 4. The drill bit should be controlled within a certain length range due to the limitation of its stroke. The drill bit speed is the slow speed in the reasonable speed determined through extensive investigation. If the speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com