Automatic character spraying machine for cloth strip scroll

A type of printing machine and banner technology, applied in typewriters, power transmission devices, printing, etc., can solve the problems of cumbersome procedures, polluting cloth width, ink flow, etc., and achieve the effect of convenient use, fewer operators, and fast printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

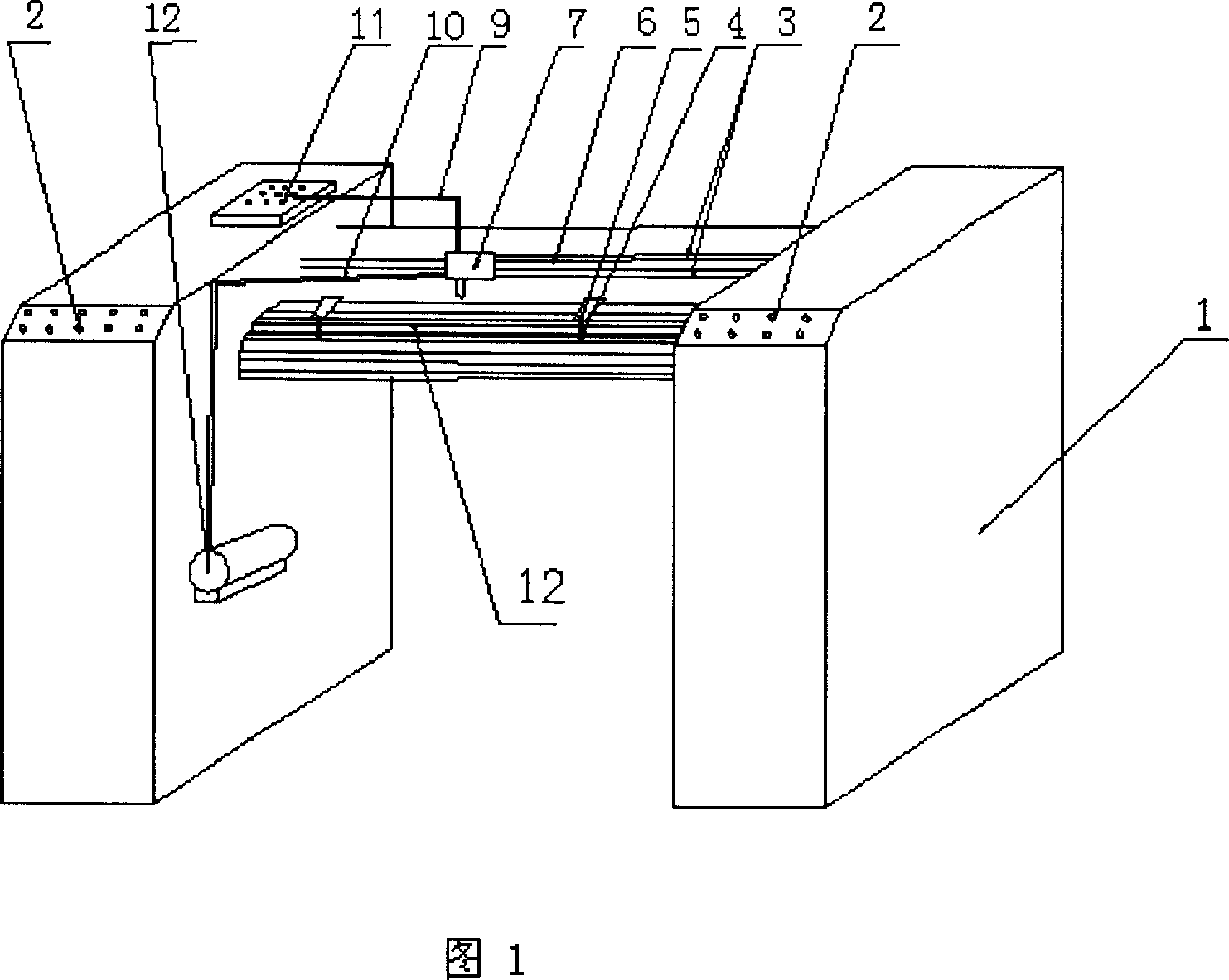

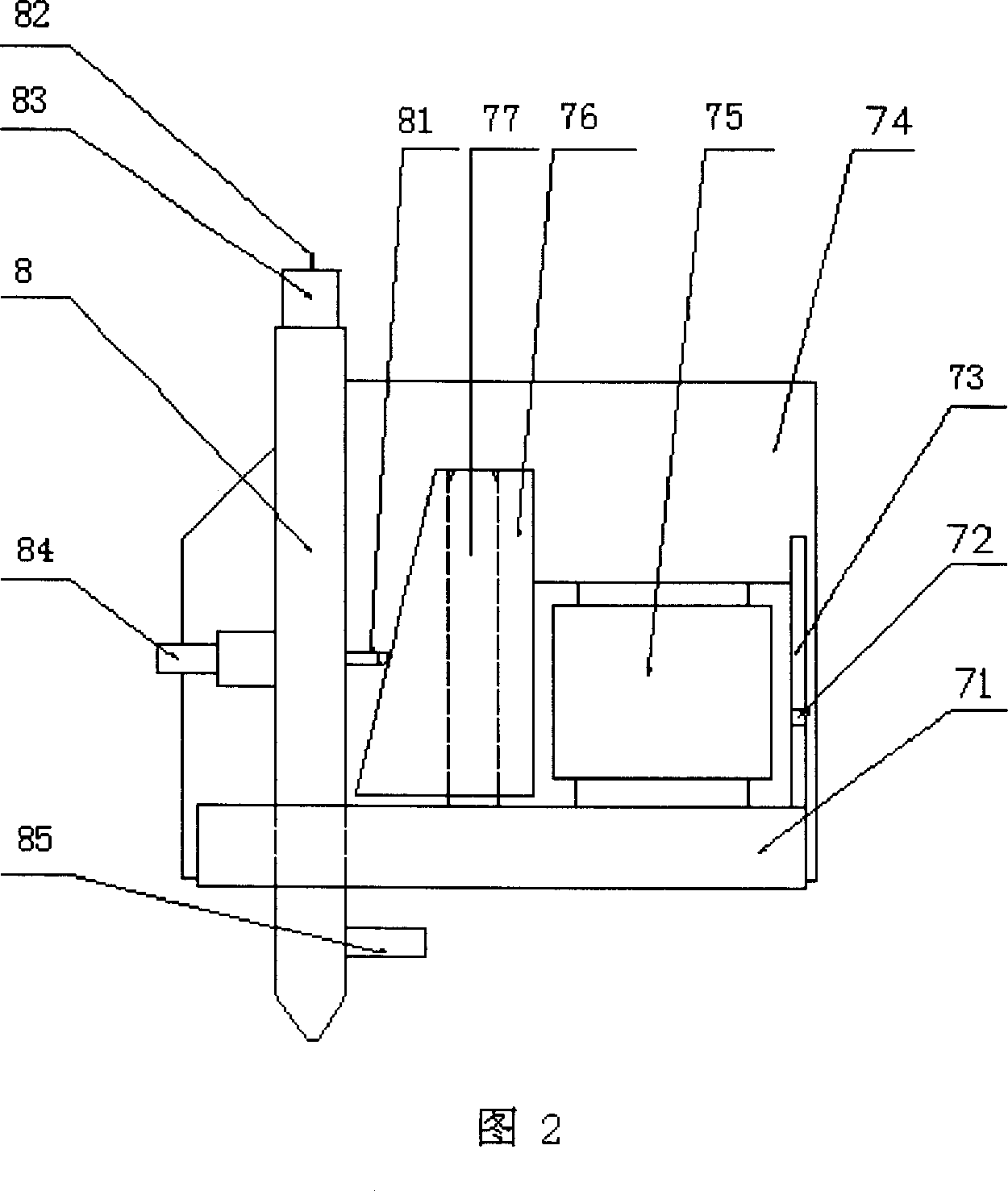

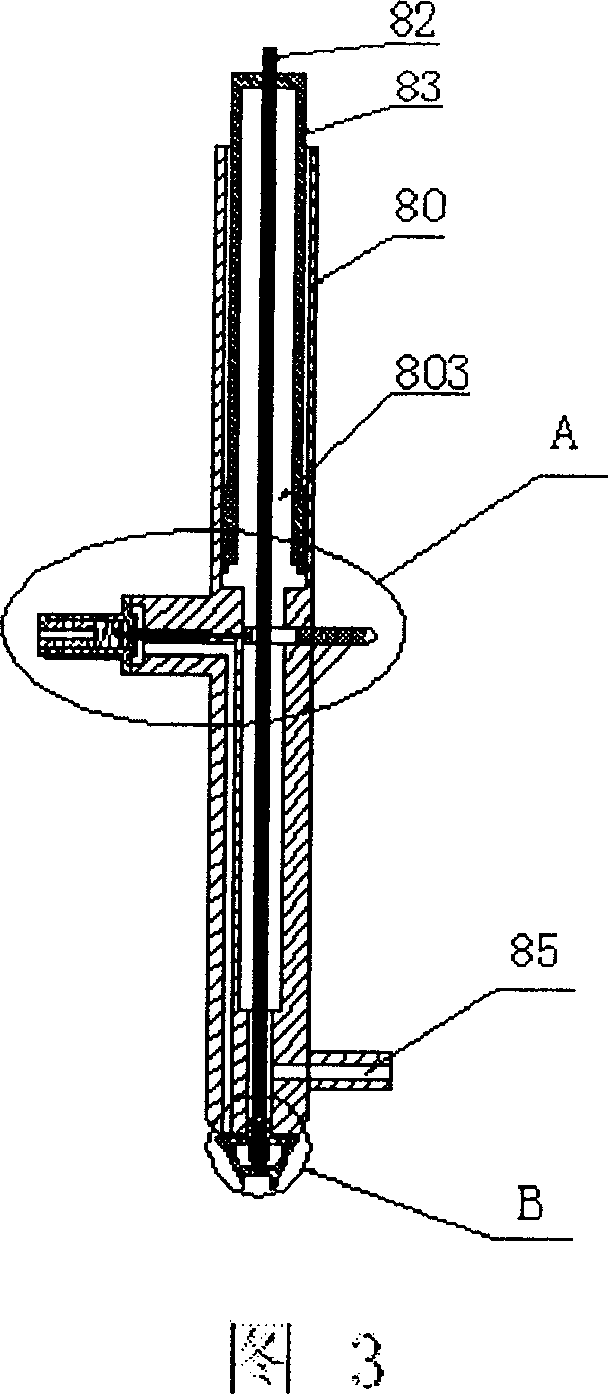

[0016] Embodiment 1: an automatic cloth banner printing machine, including a rack cabinet (1), a printing signal input system, a printing control system, a cloth width synchronous transmission system, an ink supply system, and a printing system, wherein the printing system includes a printing trolley (7) , the printing carriage (7) is equipped with a pneumatic inkjet nozzle (8), and has a constant pressure air source and a constant pressure ink supply system to match it. Printing dolly (7) comprises trolley frame (74), and on the facade of trolley frame (74) is fixedly connected a vertically sliding electromagnet (75) and a limit guide block (76), and limit guide block (76) One side near the pneumatic nozzle head (8) is an inclined surface, which matches with the intake valve touch switch valve stem (81) on the pneumatic nozzle head (8); the limit guide block (76 ) has a vertical guide groove (77) on the body; the bottom of the slide block of the electromagnet (75) is fixedly ...

Embodiment 2

[0020] Embodiment 2: The difference with Embodiment 1 is: the pneumatic nozzle (8) and the electromagnet (75) are all fixed on the trolley frame (74) of the typing cart, and the electromagnetic slide block of the electromagnet is directly connected to the air intake. Valve (84) touches switch valve stem (81) to cooperate. This design is simpler than Embodiment 1.

Embodiment 3

[0021] Embodiment 3: Different from Embodiment 2, there are multiple pneumatic inkjet nozzles and corresponding electromagnets, and each inkjet inkjet provides inks of different colors. If there are three inkjet nozzles, three colors are used. The corresponding printing control system adopts three-color control, so that the cloth can be sprayed in color.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com