Method for processing high accuracy high strength bolt

A technology of high-strength bolts and processing methods, which is applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems that bolt joints cannot meet the requirements of use, the thread processing of dies cannot meet the requirements, and the efficiency of turning threads is low. Achieve the effects of saving clamping length, less margin for finishing turning, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiment of the present invention: the method for processing hex bolt

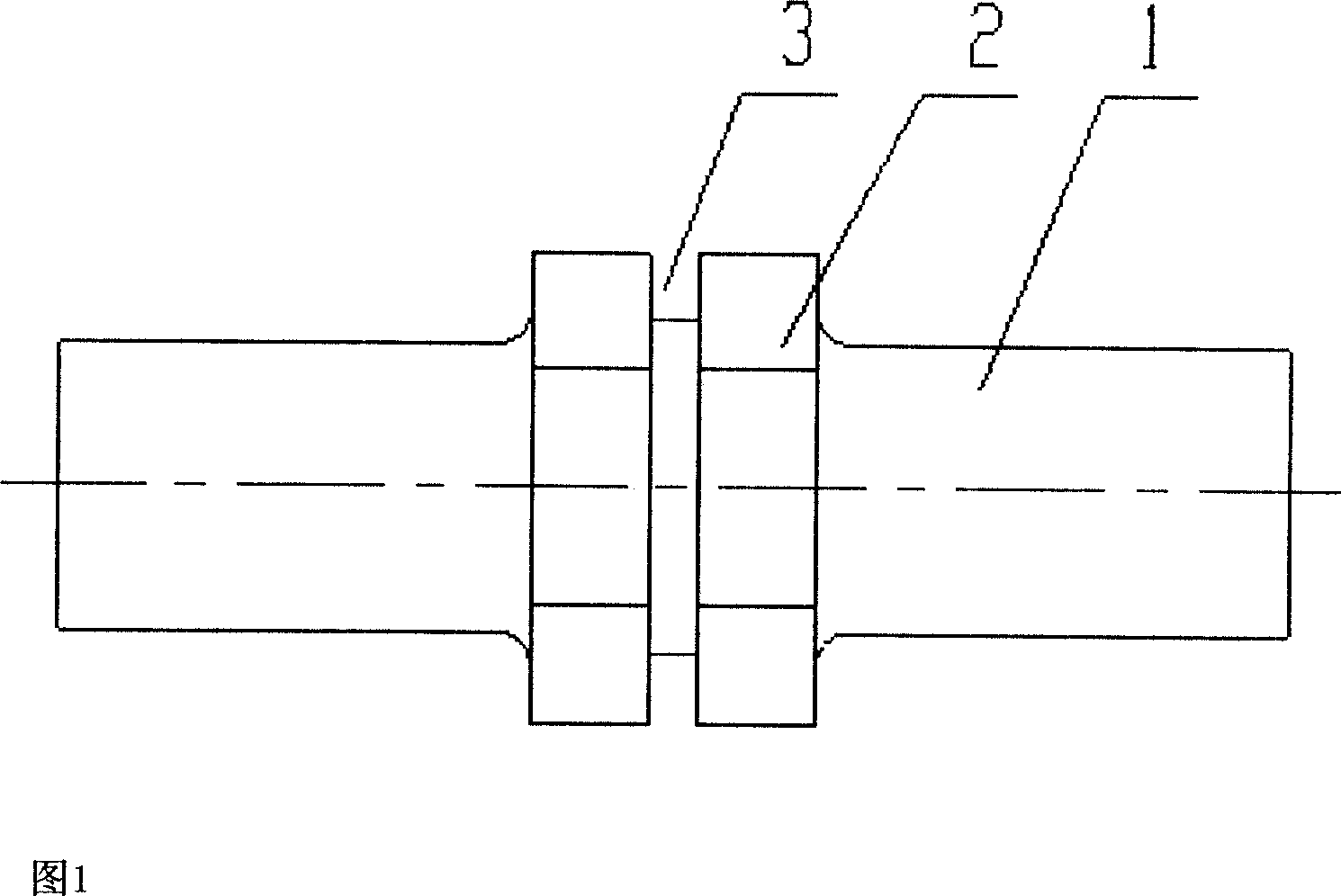

[0015] It comprises the following steps; as shown in Figure 1, a, stock preparation, prepare the hexagonal 40Cr bar stock according to the hexagonal bolt of processing; In order to reduce the cutting amount, the number of hexagonal bolts that can be processed by each 40Cr bar stock is preferably 2 Integer multiples.

[0016] b. Rough turning, cut the prepared hexagonal 40Cr rod blank into sections, so that each blank section 1 obtained after cutting into sections can process two hexagonal bolts, and then cut the two ends of the blank section 1 on a common lathe. The position of the processed thread and size is turned into a cylinder, and a cutting groove 3 is turned in the middle of the blank section 1; the cutting groove 3 is smaller than the outer dimension of the blank section 1, and the width and depth of the cutting groove 3 are to ensure that the cutter does not break when cutting. knife is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com