Strip steel surface defect detecting platform based on machine sight and its detecting method

A defect testing and machine vision technology, applied in the direction of optical testing flaws/defects, etc., it can solve the problems of sample sampling of design defects, difficulty in system debugging, different shapes, colors, and conspicuousness, and can only be displayed in images under circumstances, etc. Achieve the effect of reducing implementation risks, improving development efficiency, and saving development time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

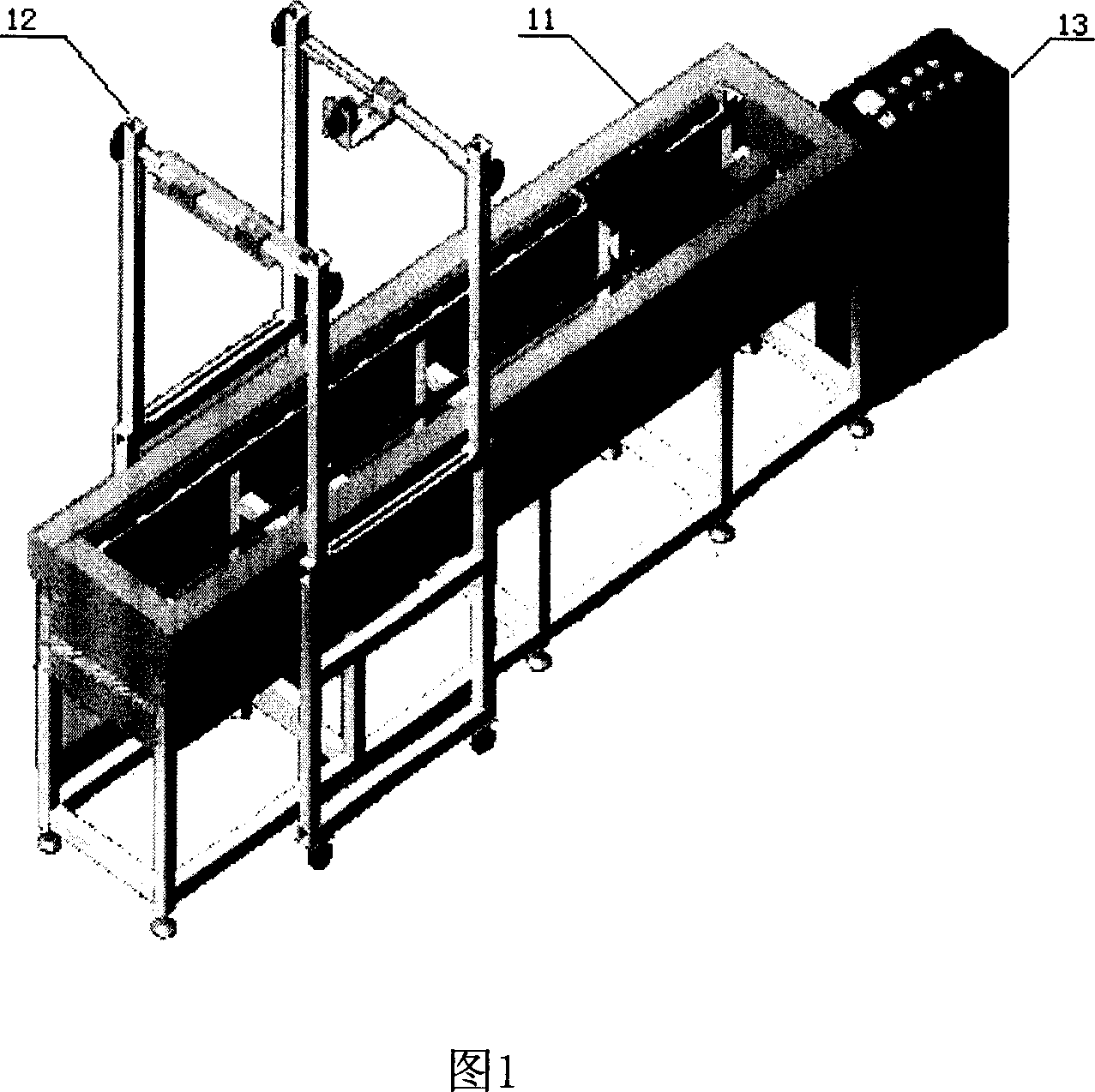

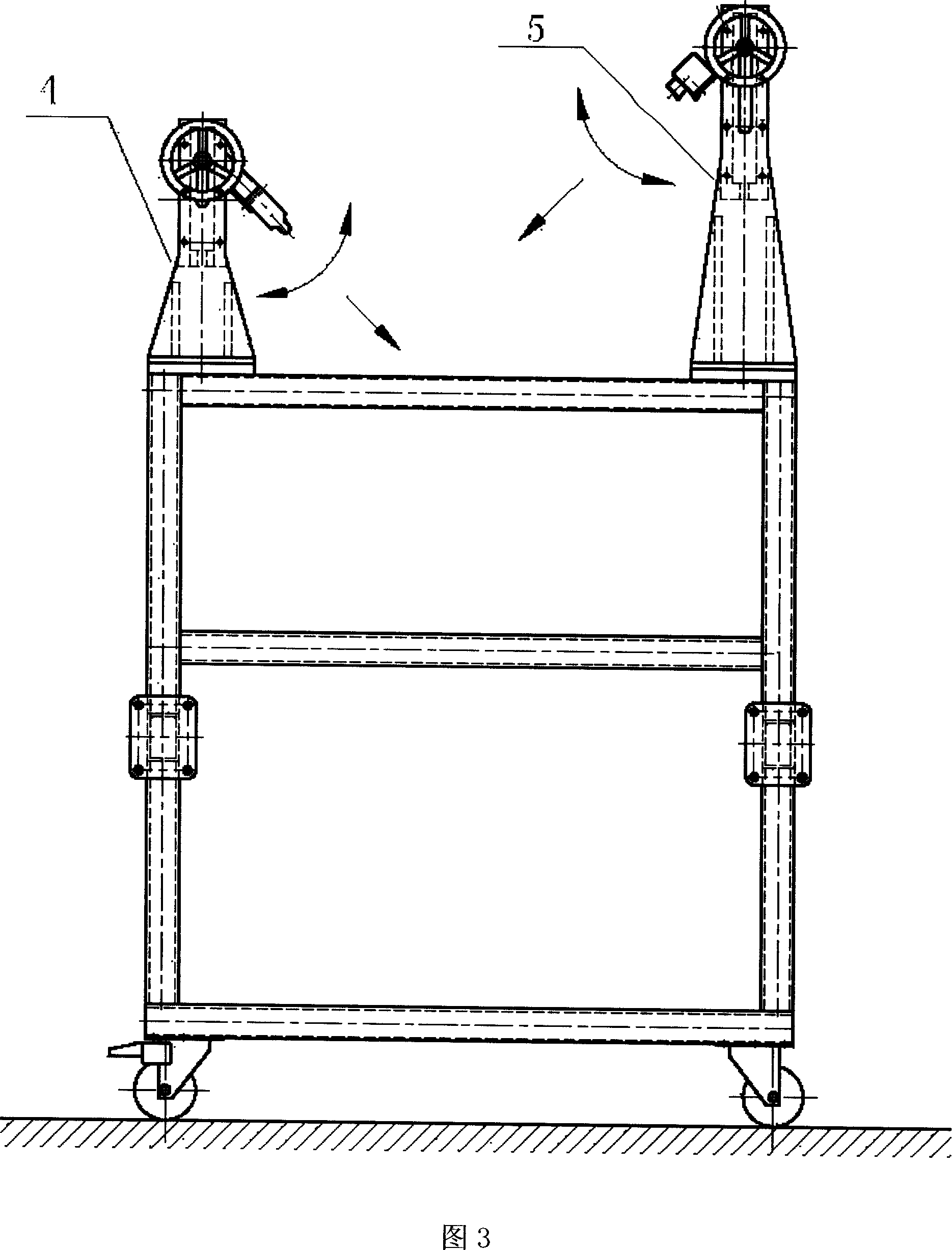

[0026] As shown in FIG. 1 , the strip steel surface defect testing platform based on machine vision of the present invention consists of three parts: a strip steel simulation motion platform 11 , a linear motion control device 12 , a camera and a light source adjustment device 13 . The strip steel simulation motion platform 11 effectively absorbs the strip steel samples with defects and can move smoothly in a straight line; the linear motion control device 12 controls the platform 11 to simulate a strip steel production line to perform uniform and accelerated motion; the camera and The light source adjustment device 13 realizes the multi-angle adjustment of the high-speed linear array industrial camera and the light source, and collects moving images of steel strip defect samples in real time.

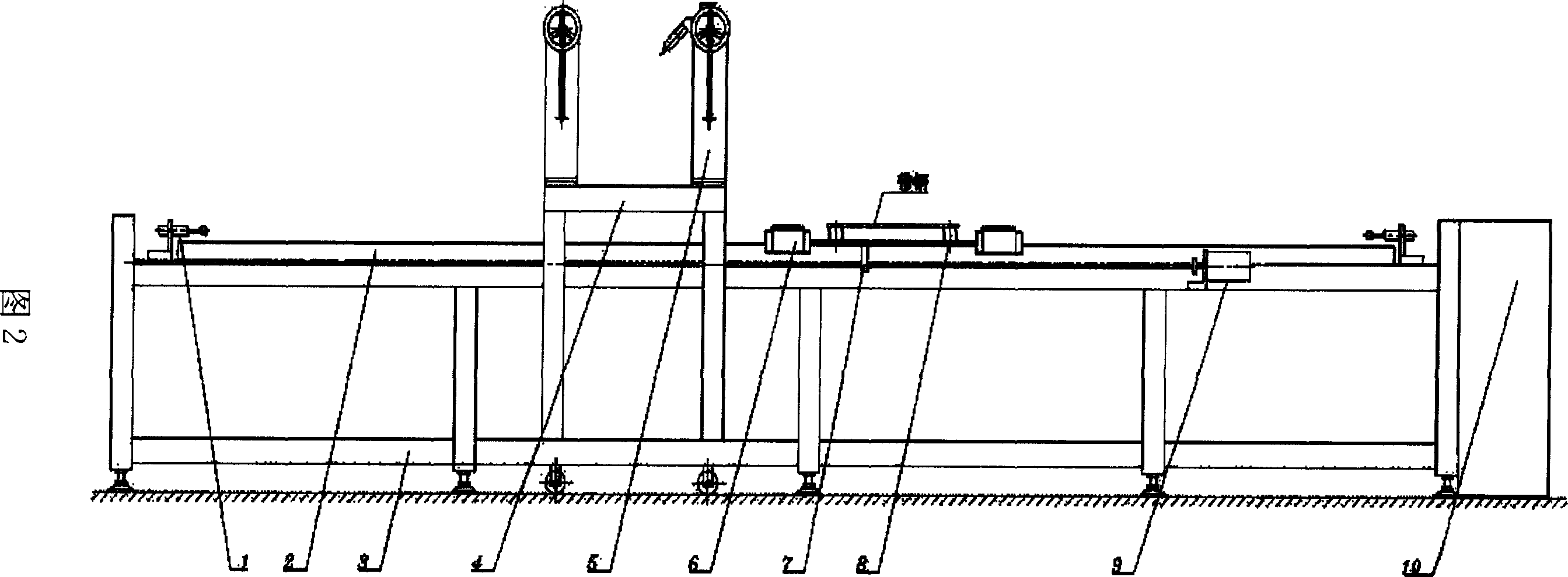

[0027] The structure of the machine vision-based strip surface defect testing platform of the present invention is shown in FIG. 2 .

[0028] The strip steel simulation motion platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com