Sintered metal parts and method for the manufacturing thereof

A technology of metal parts and sintered metal, which is applied in the field of powder metal parts, can solve the problems of reducing bending fatigue strength, increasing additional costs, and low contact fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

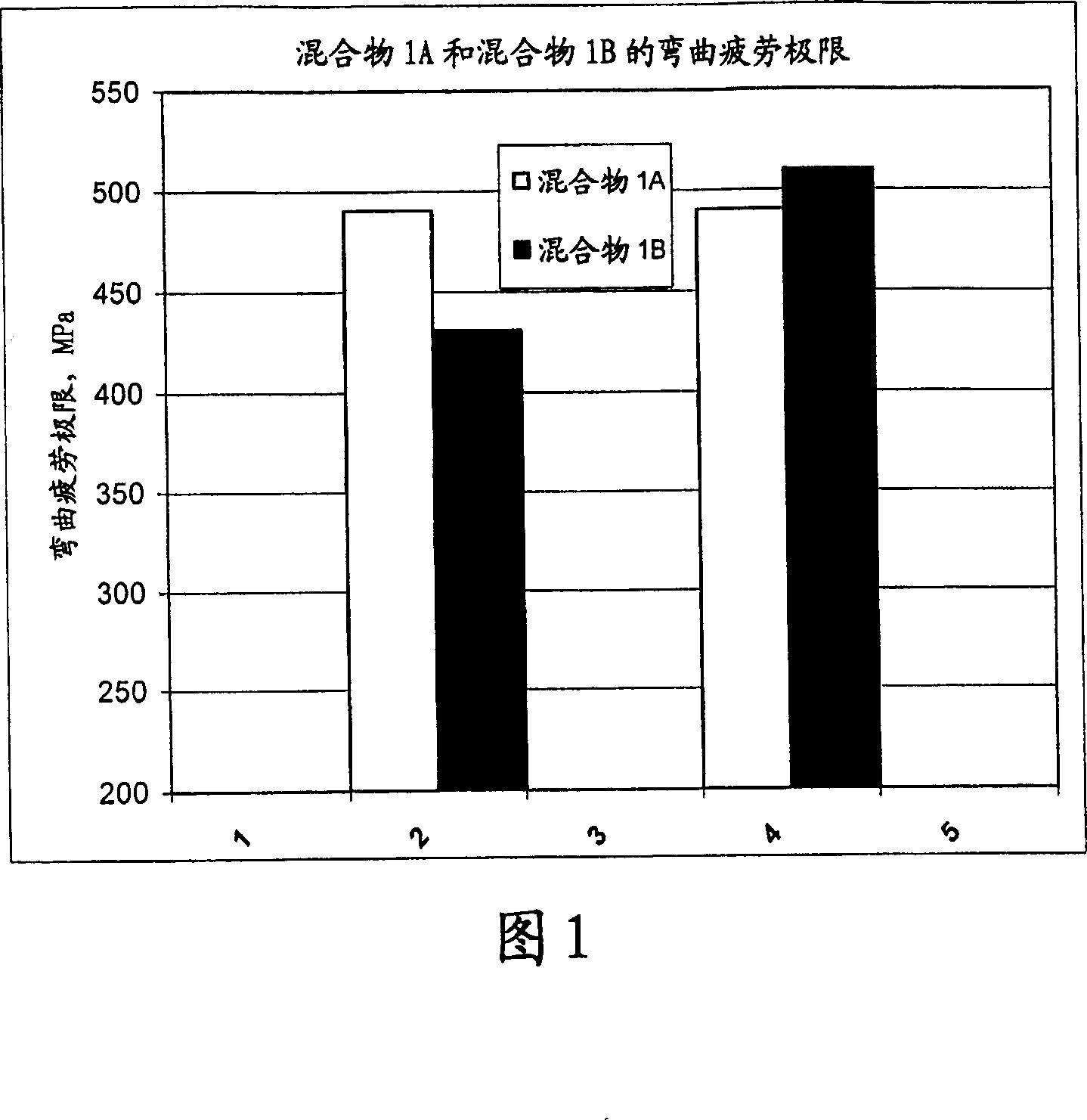

[0057] Two mixtures were prepared by mixing well before pressing: Mixture 1A and Mixture 1B.

[0058] Mixture 1A was based on powder A with the addition of 0.2% by weight of graphite and 0.8% by weight of H wax.

[0059] Mixture 1B was based on powder B with the addition of 0.2% by weight of graphite and 0.2% by weight of cetyl-trimethoxysilane.

[0060] Pressed FS strength test bars according to ISO 3928.

[0061] A test bar based on Mixture 1A was compressed to 7.1 g / cm 3 The density of the green body was pre-sintered at 780°C for 30 minutes in an atmosphere containing 90% nitrogen and 10% hydrogen. After sintering, the sample was subjected to a second pressing at a pressure of 1100 MPa and finally sintered at 1280° C. for 30 minutes in an atmosphere containing 90% nitrogen and 10% hydrogen. The measured sintered density reaches 7.61g / cm 3 .

[0062] The samples prepared with Mixture 1B were pressed at 1100 MPa by a single press method, followed by sintering at 1280°C f...

example 2

[0073] Two mixtures were prepared by mixing well before pressing: Mixture 2C and Mixture 2D.

[0074] Mixture 2C was based on powder C with the addition of 0.7% nickel powder, 0.2% by weight graphite and 0.8% by weight H wax.

[0075] Mixture 2D was based on powder D with the addition of 0.7% nickel powder, 0.2% graphite and 0.2% cetyl-trimethoxysilane.

[0076] FS-strength test bars were prepared according to ISO 3928.

[0077] Compress the test bar based on mixture 2C to 7.1 g / cm 3 The density of the green body was pre-sintered at 780°C for 30 minutes in an atmosphere containing 90% nitrogen and 10% hydrogen. After sintering, the sample was subjected to a second pressing at a pressure of 1100 MPa and finally sintered at 1280° C. for 30 minutes in an atmosphere containing 90% nitrogen and 10% hydrogen. The measured sintered density reaches 7.63g / cm 3 .

[0078] The test bars prepared with mixture 2D were pressed at 1100 MPa by one-shot pressing, followed by sintering at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com