Once ultrasonic cutting preparation method of automatic yarn spreading pre-steeping

A technology of ultrasonic cutting and automatic wire laying, which is applied in filament/thread forming, textile and papermaking, fiber processing, etc. It can solve the problems of difficulty in guaranteeing production efficiency, waste of raw materials, etc. The effect of service life and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

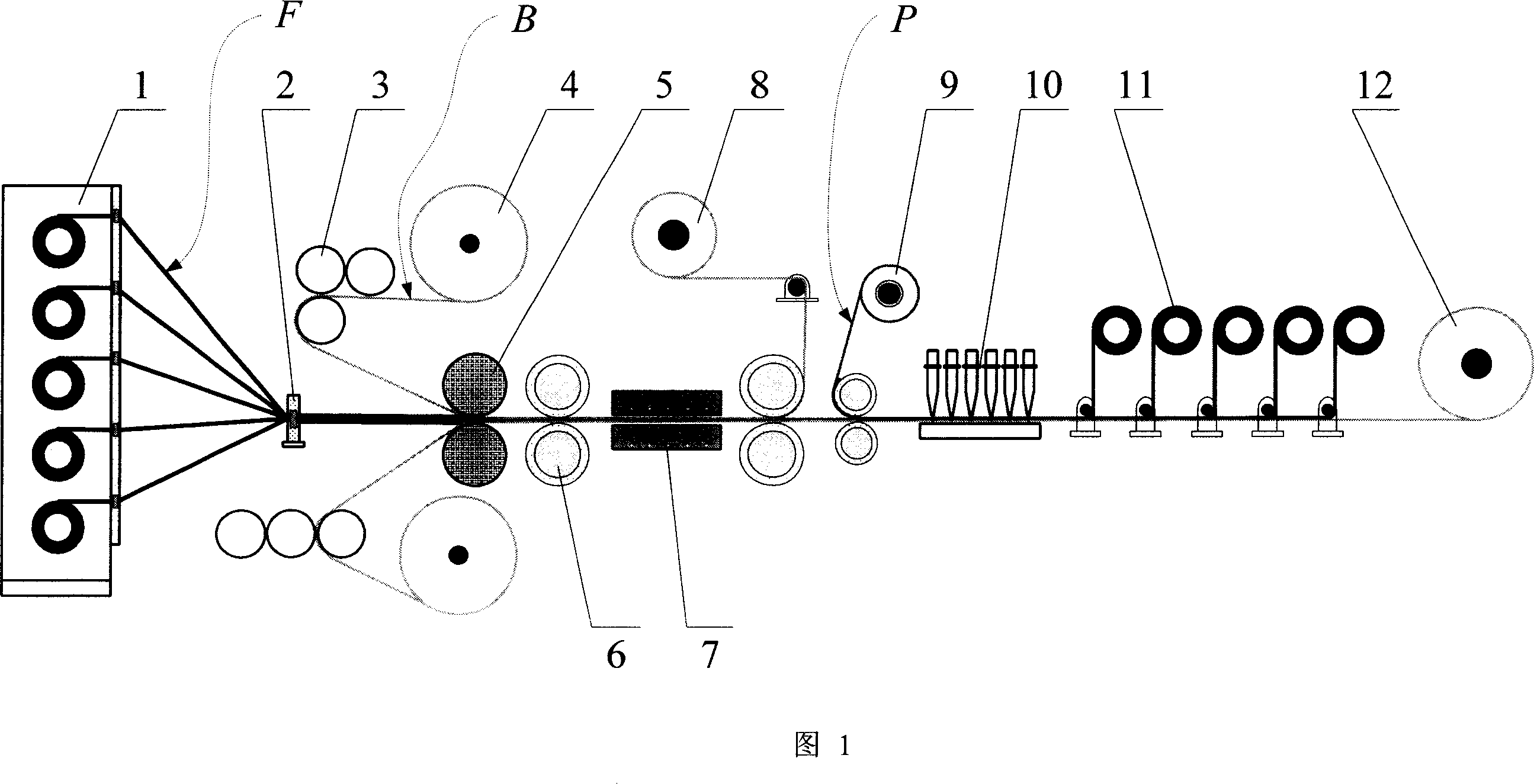

[0018] The method provided by the present invention will be described below with reference to FIG. 1 .

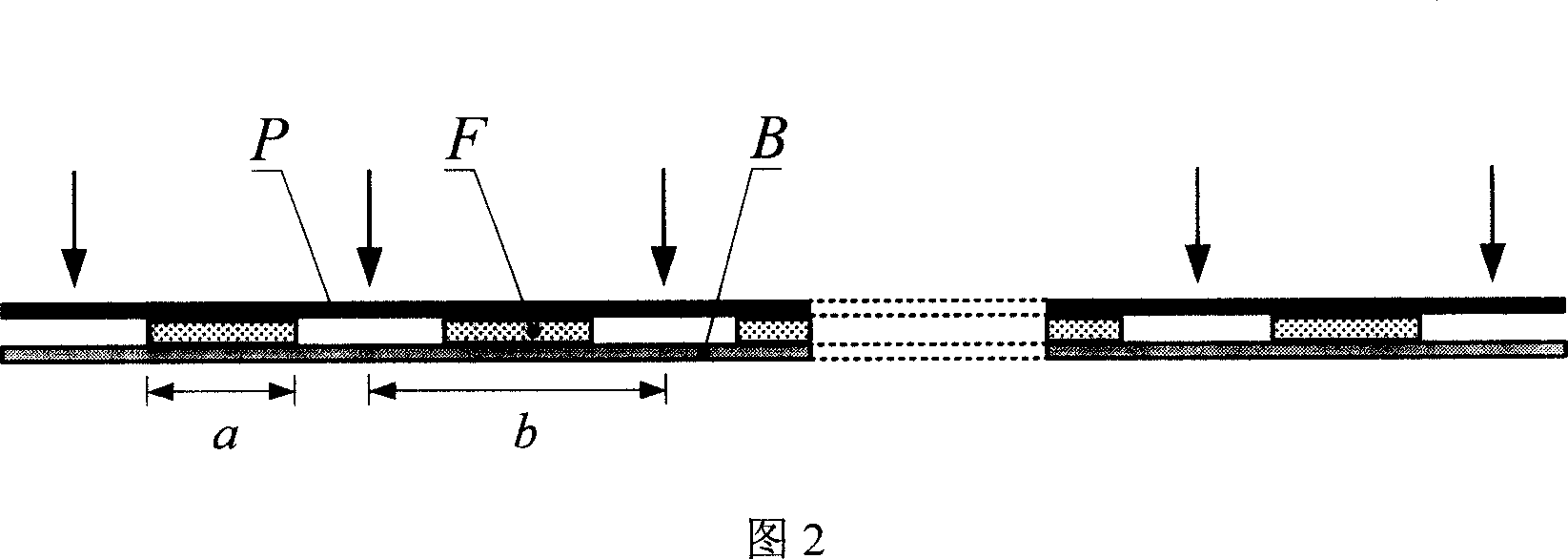

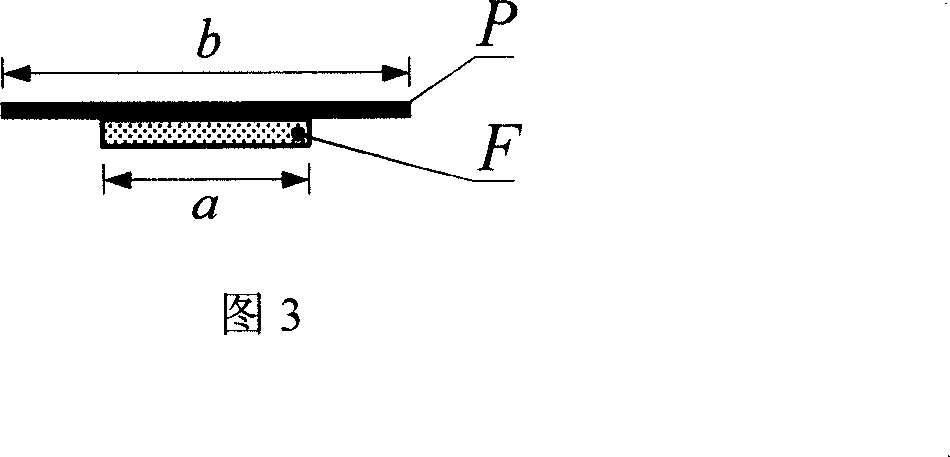

[0019] As shown in Figure 1, after the multiple fiber bundles are exported from the creel 1, the fiber bundles are arranged in parallel by the yarn guide frame 2, and a cutting gap is reserved between each other. At the same time, the hot-melt resin is coated on the Prepare an adhesive film on the backing paper B drawn from the backing paper reel 4. The backing paper B has a layer on the top and bottom, and forms a sandwich structure with the flattened fiber F. Under the traction of the traction roller 6, they are heat-pressed together. Roller 5, the adhesive film is melted and impregnated with fiber F and then cooled and formed by cooling platform 7, and the upper backing paper B is collected by the upper backing paper taking reel 8, and then a layer of film P is coated on the upper surface of the fiber F, and the film P is drawn from the film reel 9 , and then use a set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com