Piston for the crosshead engine

A crosshead type engine technology, which is applied to the engine, especially the piston of a two-stroke large diesel engine, can solve the problems of affecting the cooling effect and the cooling of the bottom of the hole, and achieve the effect of improving the cooling effect and high heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

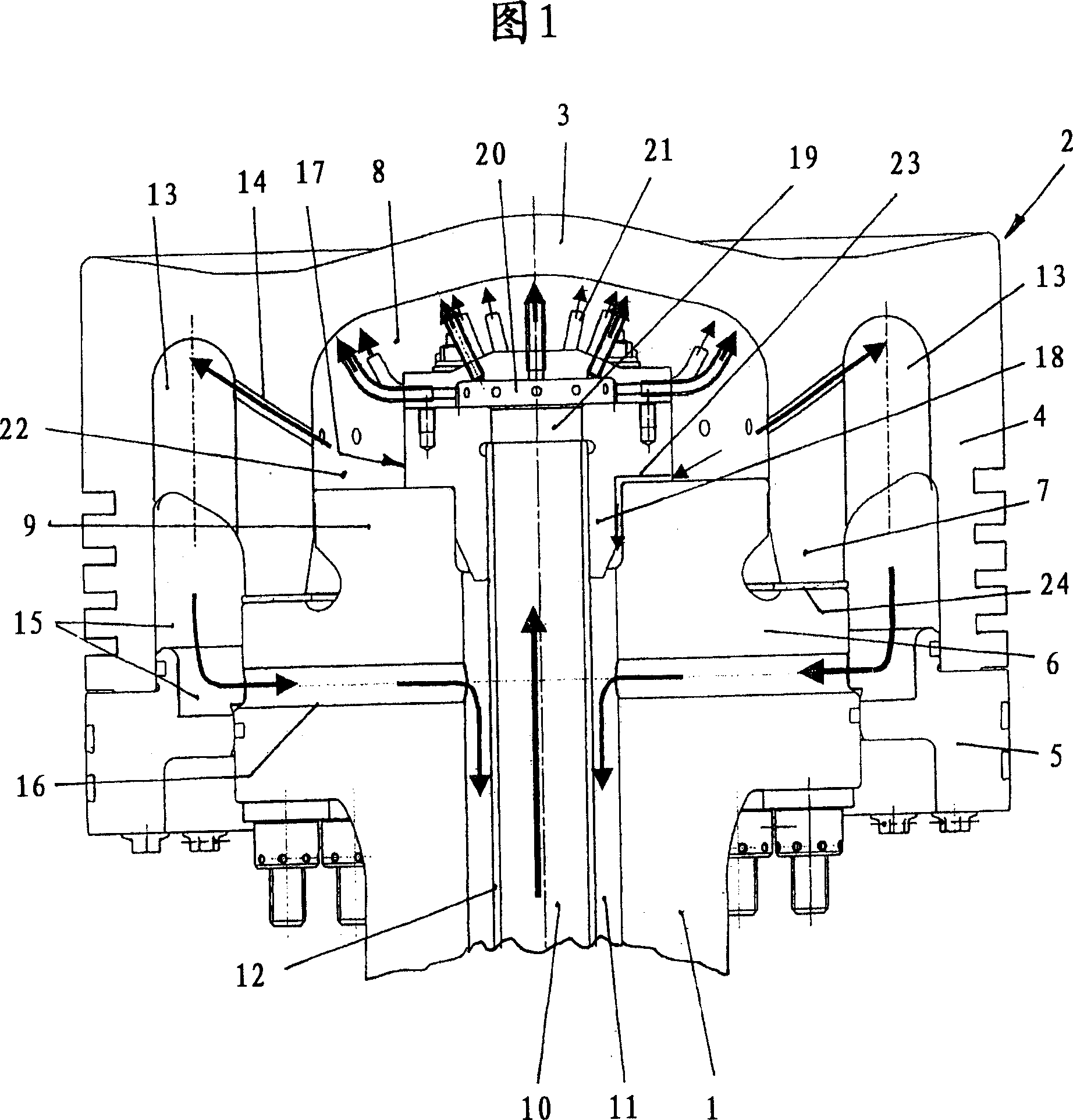

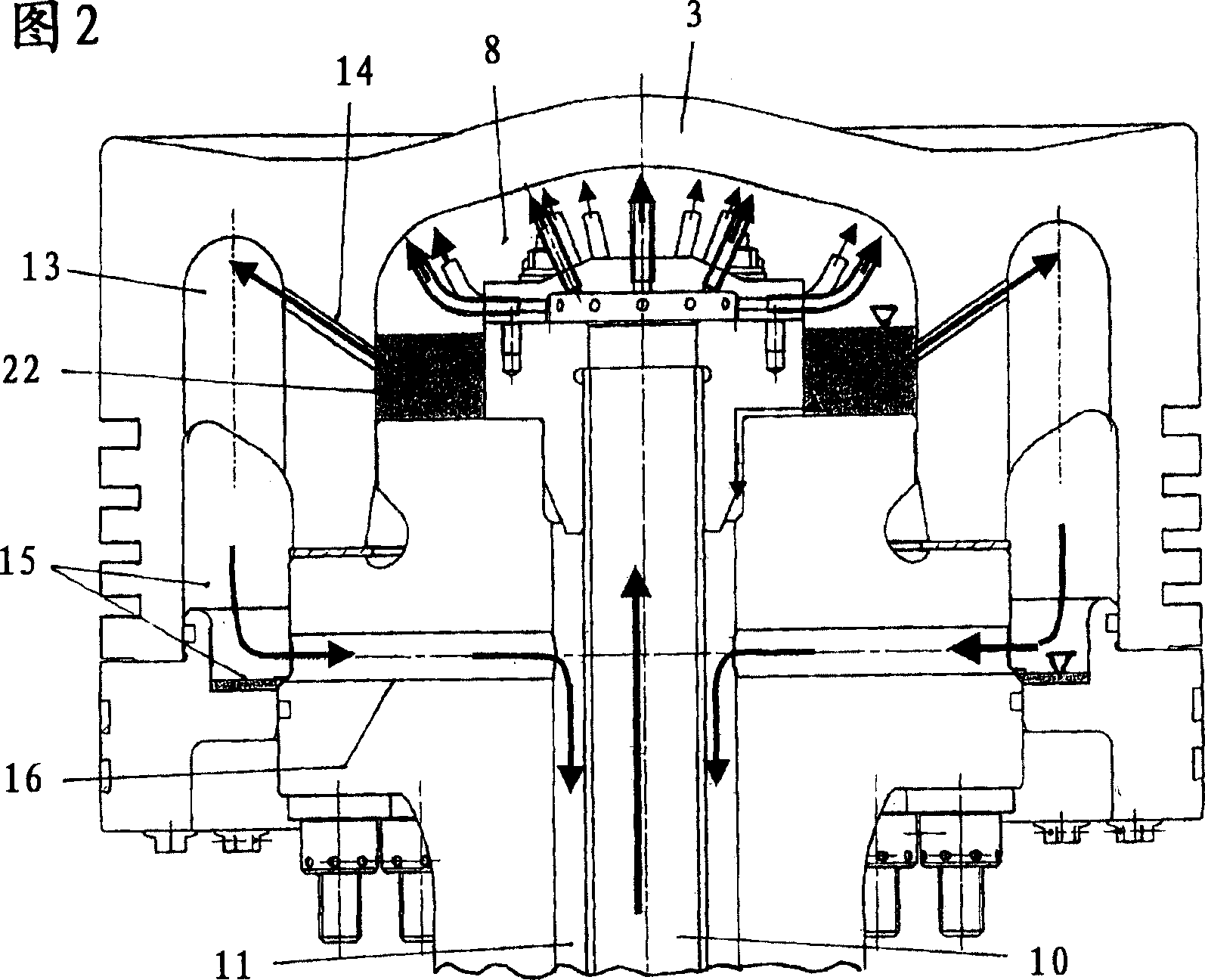

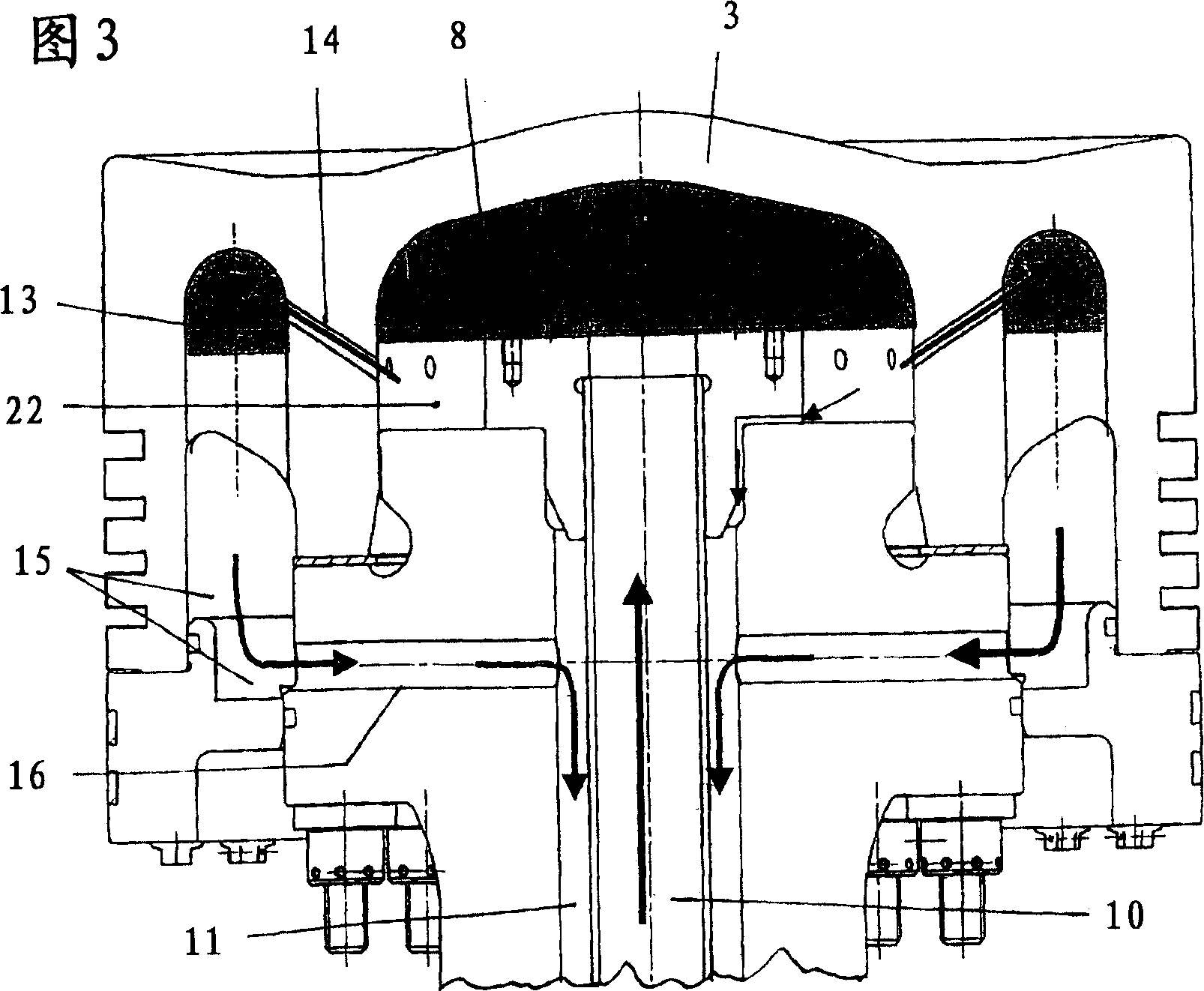

[0018] The main field of application of the present invention is two-stroke large diesel engines in a crosshead configuration, for example in ship drives and the like. The structure and principle of action of such engines are known per se.

[0019] The piston shown in FIG. 1 is connected via a piston rod 1 to a crosshead, not shown in more detail. The piston comprises a piston upper part 2 with a piston head 3 facing the combustion chamber and a piston skirt 4 surrounding the outer edge accommodating the piston head 3, on which a piston lower part 5 is mounted. The piston upper part 2 is mounted on a flange 6 arranged in the region of the upper end of the piston rod 1 . For this purpose, the surrounding piston skirt 4 is provided with a radially inner annular strip 7 mounted on the flange 6 through the intermediate connection of a seal 24, which together with the piston head 3 delimits a piston upper part 2 as The piston head 3 is equipped with a central cooling chamber 8 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com