Electric motor screw pump

A technology of electric motor and screw pump, which is applied to machines/engines, liquid fuel engines, pumps, etc., can solve problems such as difficulty in lift, impossibility, leakage of motor heat dissipation, etc., and achieves the effect of easy process, convenient control and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

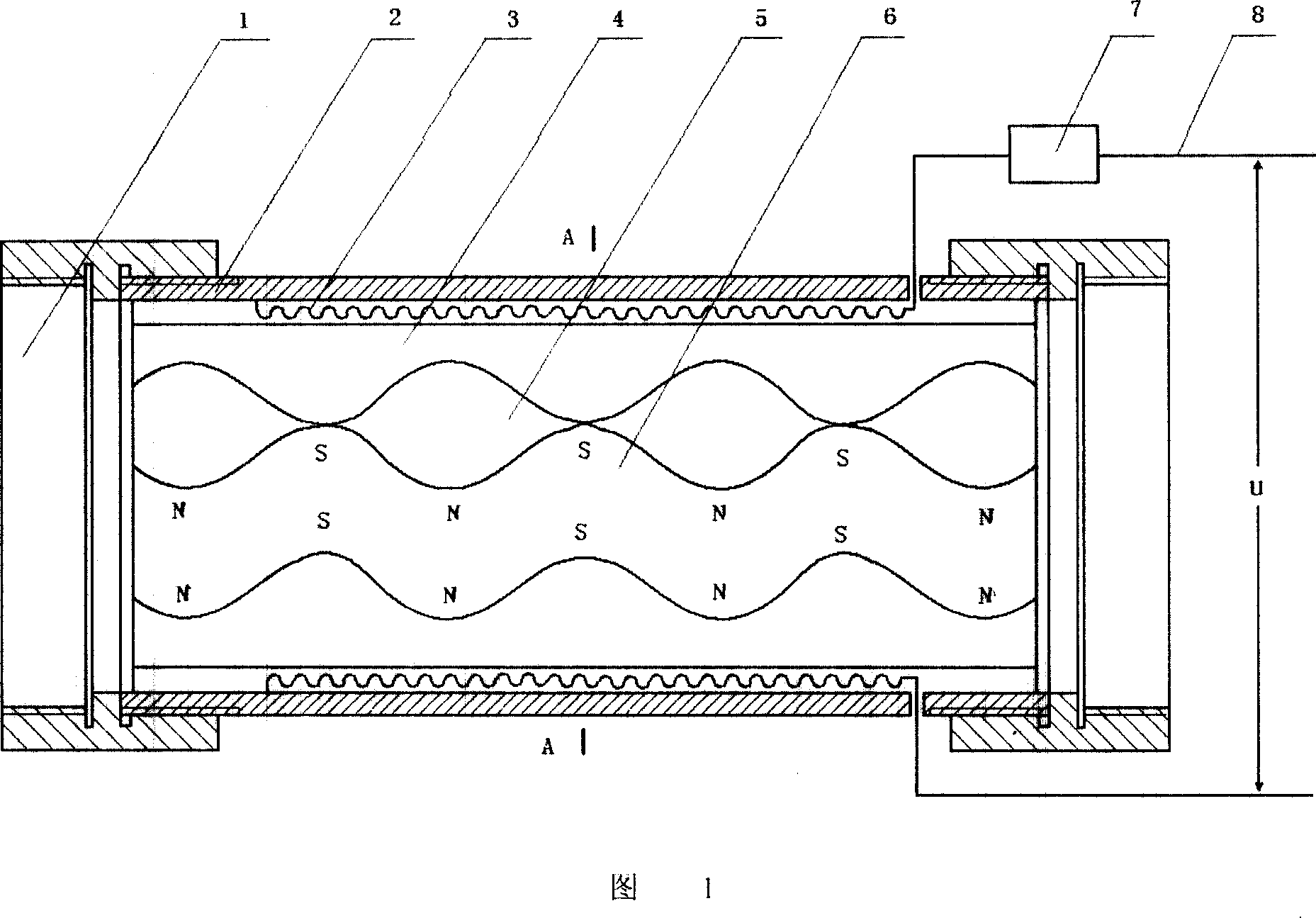

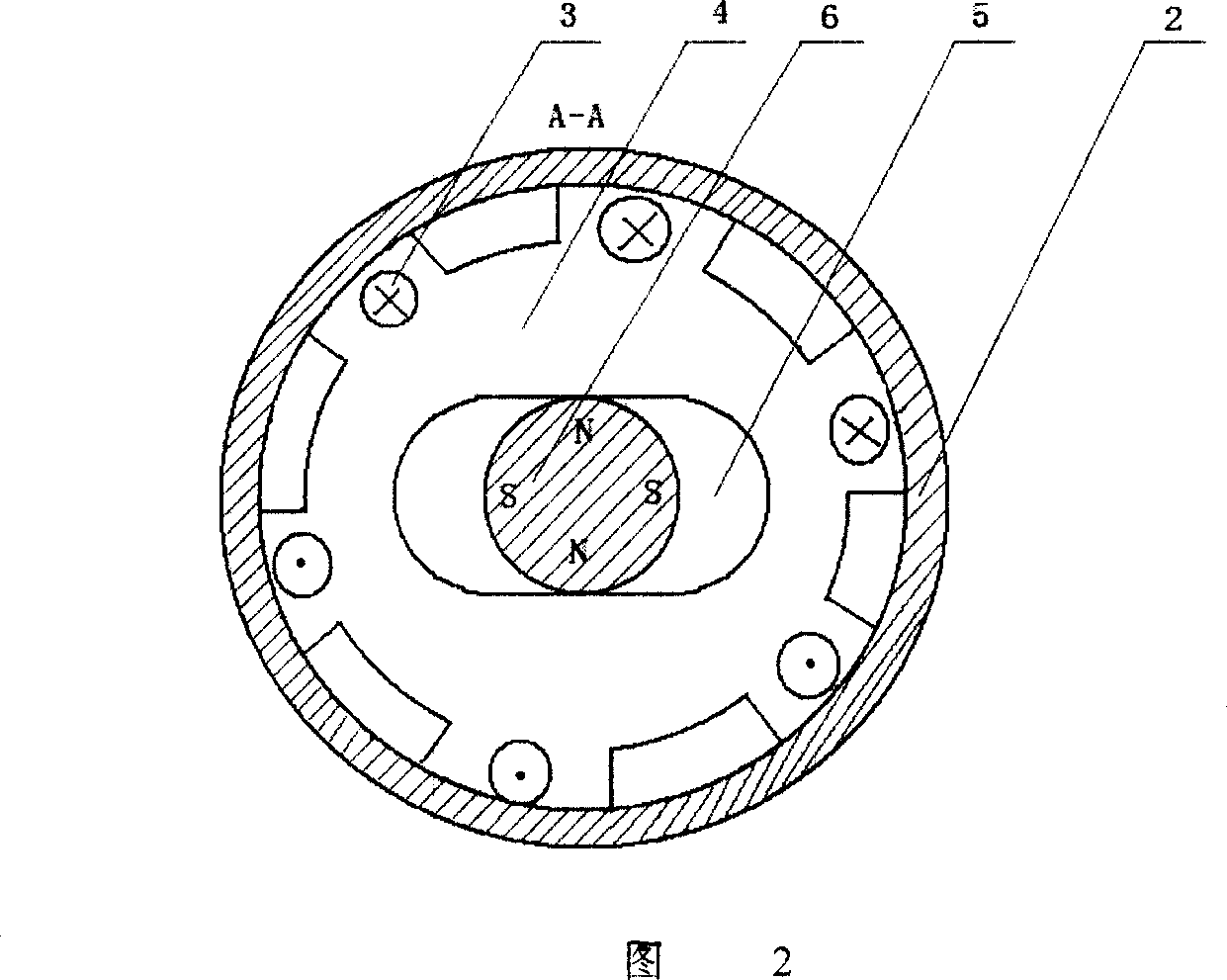

[0011] As shown in Figure 1, the interior of the stator (2) is a rubber lining (4), the middle of the rubber lining (4) is a working chamber (5), the rotor (6) is in the working chamber (5), and the rotor (6) is composed of Made of permanent magnet material, the two ends of the stator (2) are connectors (1), the stator winding (3) is fixed on the stator (2), and the stator winding (3) is connected to the power supply after the voltage-frequency controller (7) is connected in series superior.

[0012] When in use, turn on the power supply, the alternating current causes the stator winding (3) to generate an alternating magnetic field in the working cavity (5), and the alternating magnetic field acts on the rotor (6) with permanent magnetism, making the rotor (6) ) to rotate, and adjust the working voltage and alternating frequency of the stator winding (3) through the voltage-frequency control device (7), and then control the working state of the pump. Specifically, the head of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com