Working impeller of hydraulic coupler

A technology of hydraulic coupling and impeller, applied in belt/chain/gear, fluid transmission, mechanical equipment, etc., can solve the problems of increasing impeller material cost, increasing motor load inertia, increasing impeller weight, etc., to save materials , the effect of reducing load inertia and increasing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

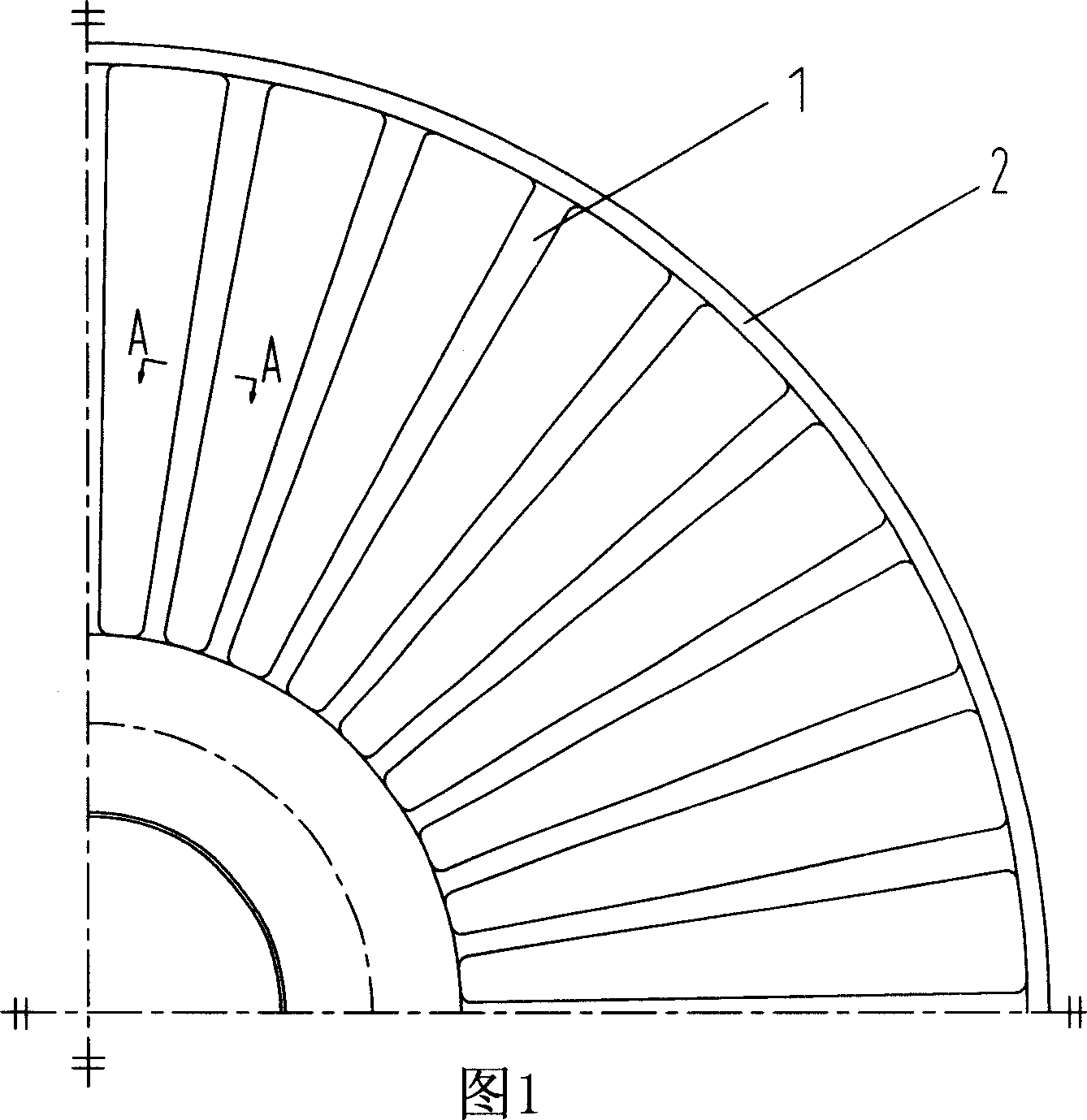

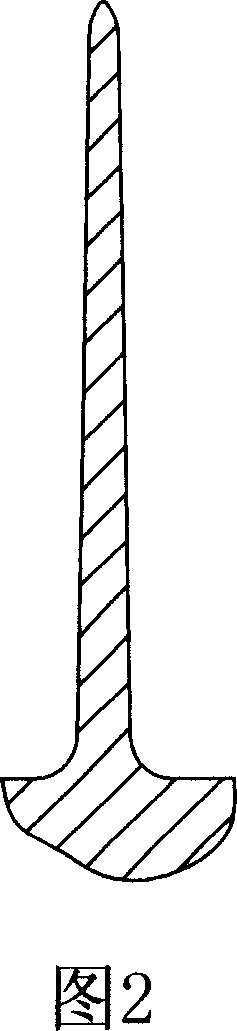

[0008] Fig. 1 is an axial projection view of a cast aluminum alloy impeller according to the present invention. In this embodiment, as shown in Figure 1, the partial structure of the working impeller of the speed-regulating fluid coupling, wherein, the impeller 2 is uniformly distributed with blades 1 in the circumferential direction, and the blades 1 are connected to the cast aluminum alloy impeller body 2 by the root. into one. The key improvement of the present invention is that the blade 1 has a variable cross-section structure both in the radial direction and in the axial direction. Specifically, as shown in Figure 1, the thickness of the blade 1 gradually increases as the diameter increases in the radial direction; referring to the cross-sectional structure along the A-A direction in Figure 1 shown in Figure 2, the blade 1 gradually moves away from the root in the axial direction , the thickness gradually decreases.

[0009] The design of the two-way variable cross-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com