Dynamic 3D laser scanning testing head

A three-dimensional laser, scanning probe technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as being unsuitable for real-time detection, and achieve the effect of avoiding scanning blind spots and strong competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

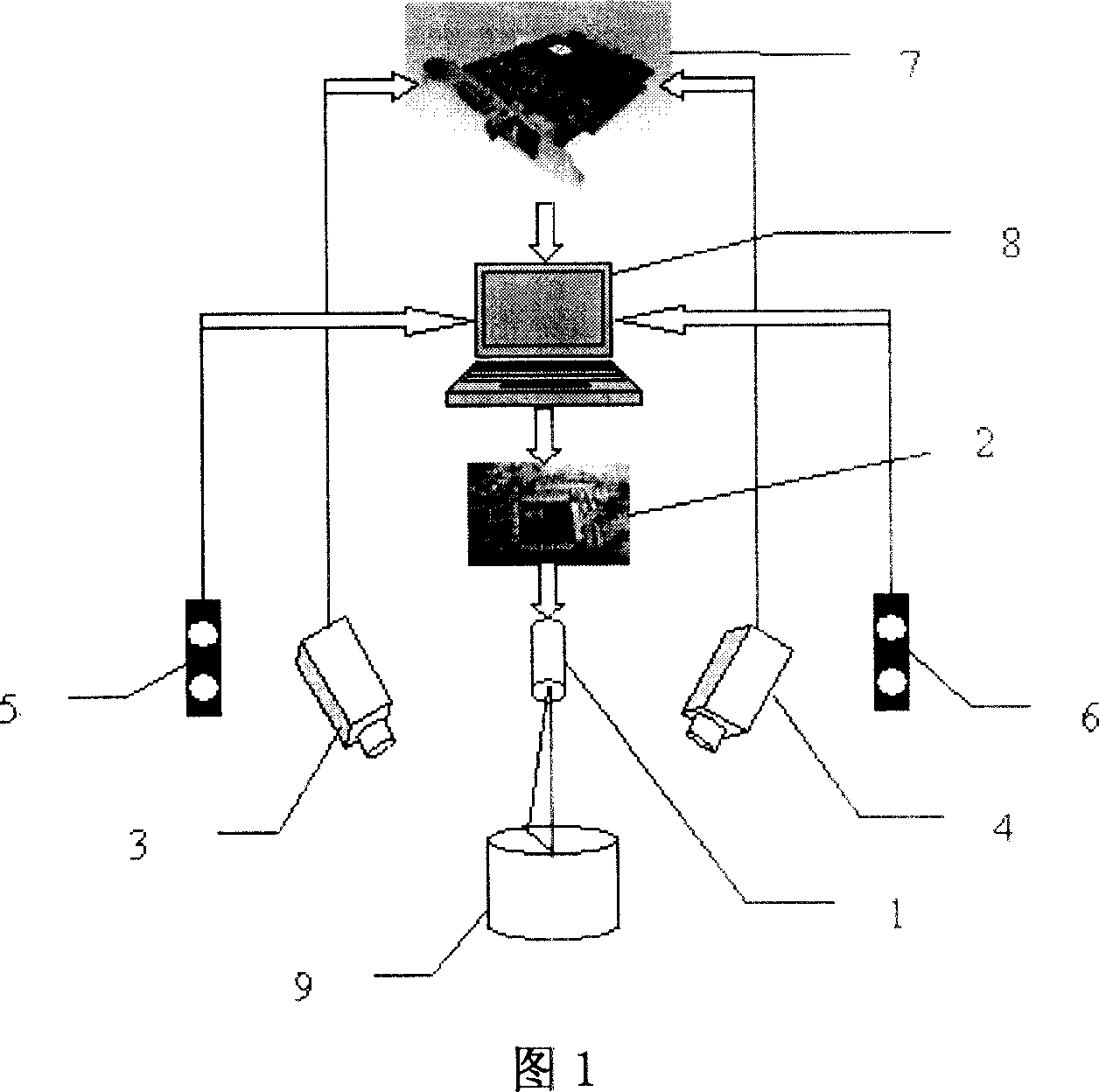

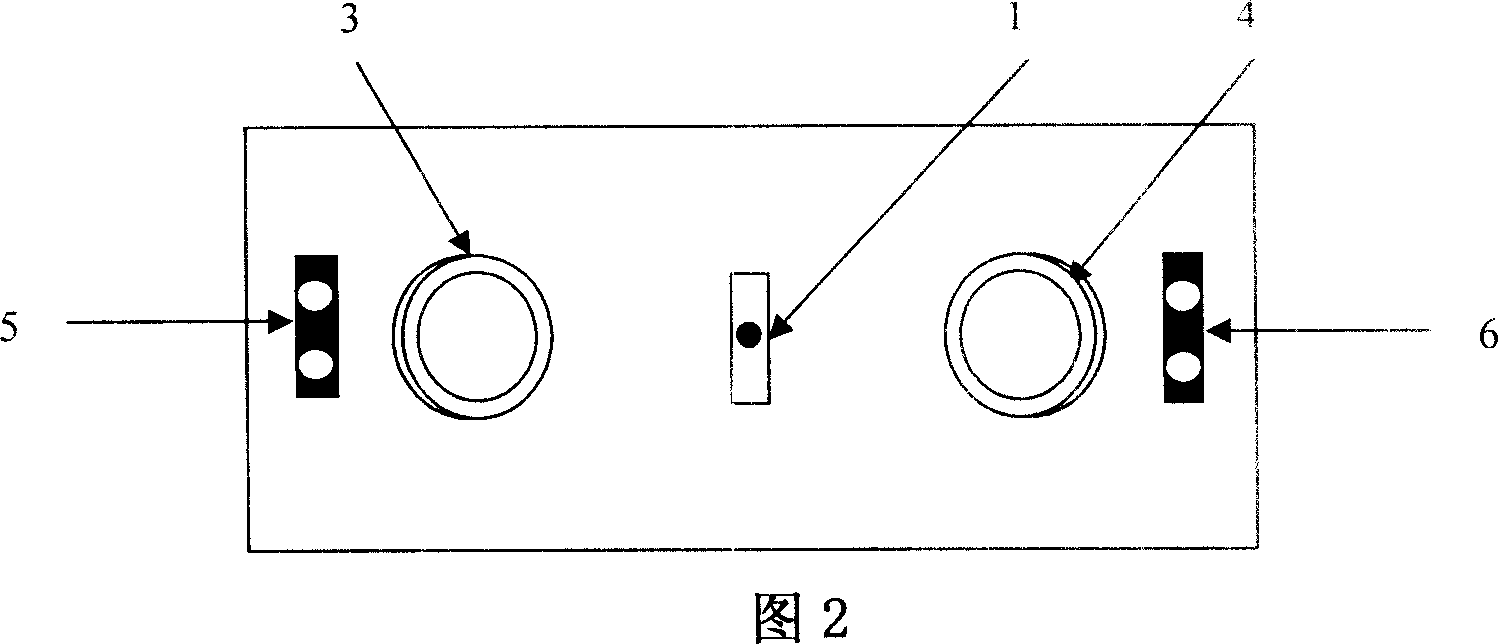

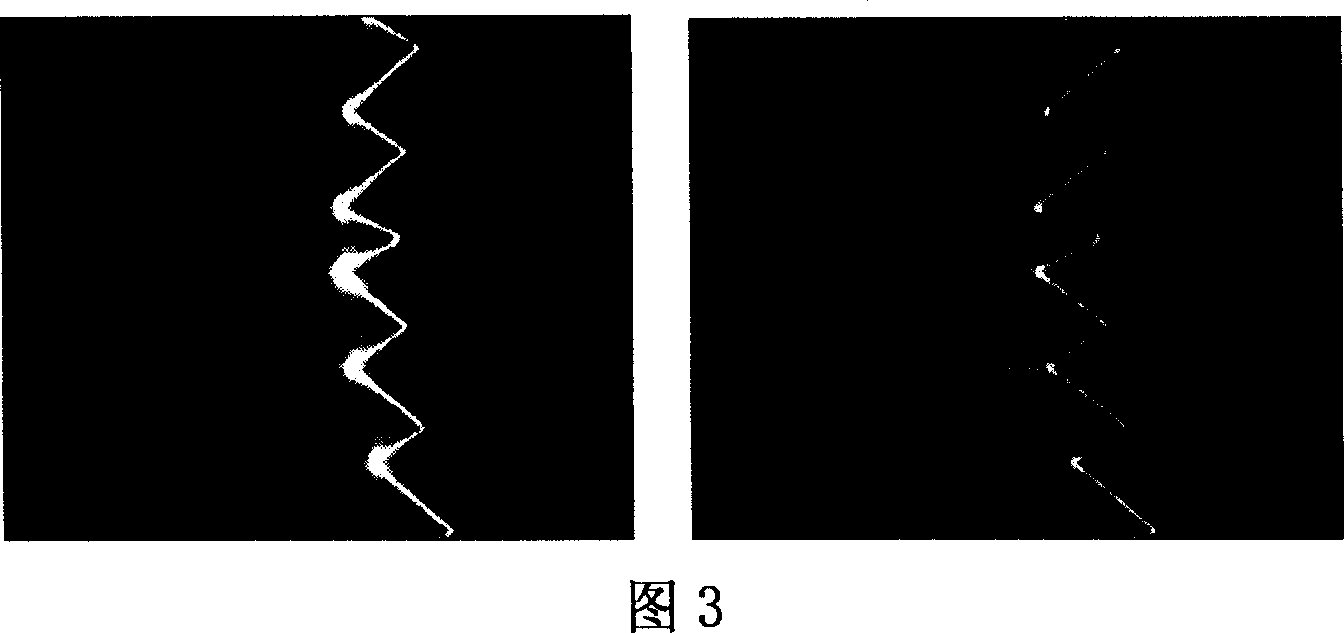

[0031] The semiconductor laser 1 uses a 650nm He-Ne laser module and a cylindrical mirror to produce a 0.1mm wide light strip projected onto the surface of the workpiece to be tested. The CCD camera 3 and CCD camera 4 form a certain angle with the laser and shoot within a certain range. The laser light stripe pattern is transmitted to the computer 8 through the image acquisition card 7, and the computer extracts the light stripe information through the corresponding image processing method, and determines the modulation amount of the laser intensity by detecting the width and continuity of the light stripe, and then through the laser intensity The control circuit 2 adjusts the light intensity. At the same time, the collision avoidance sensor 5 and the collision avoidance sensor 6 detect the distance between the probe and the workpiece 9 in real time to avoid collision between the probe and the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com