Method for preparing fine powder of silicon carbide

A technology of silicon carbide micropowder and production method, which is applied in the direction of selective deposition and solid separation, can solve the problems of material loss and affecting the production capacity of the micropowder industry, and achieve the effect of high production efficiency and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

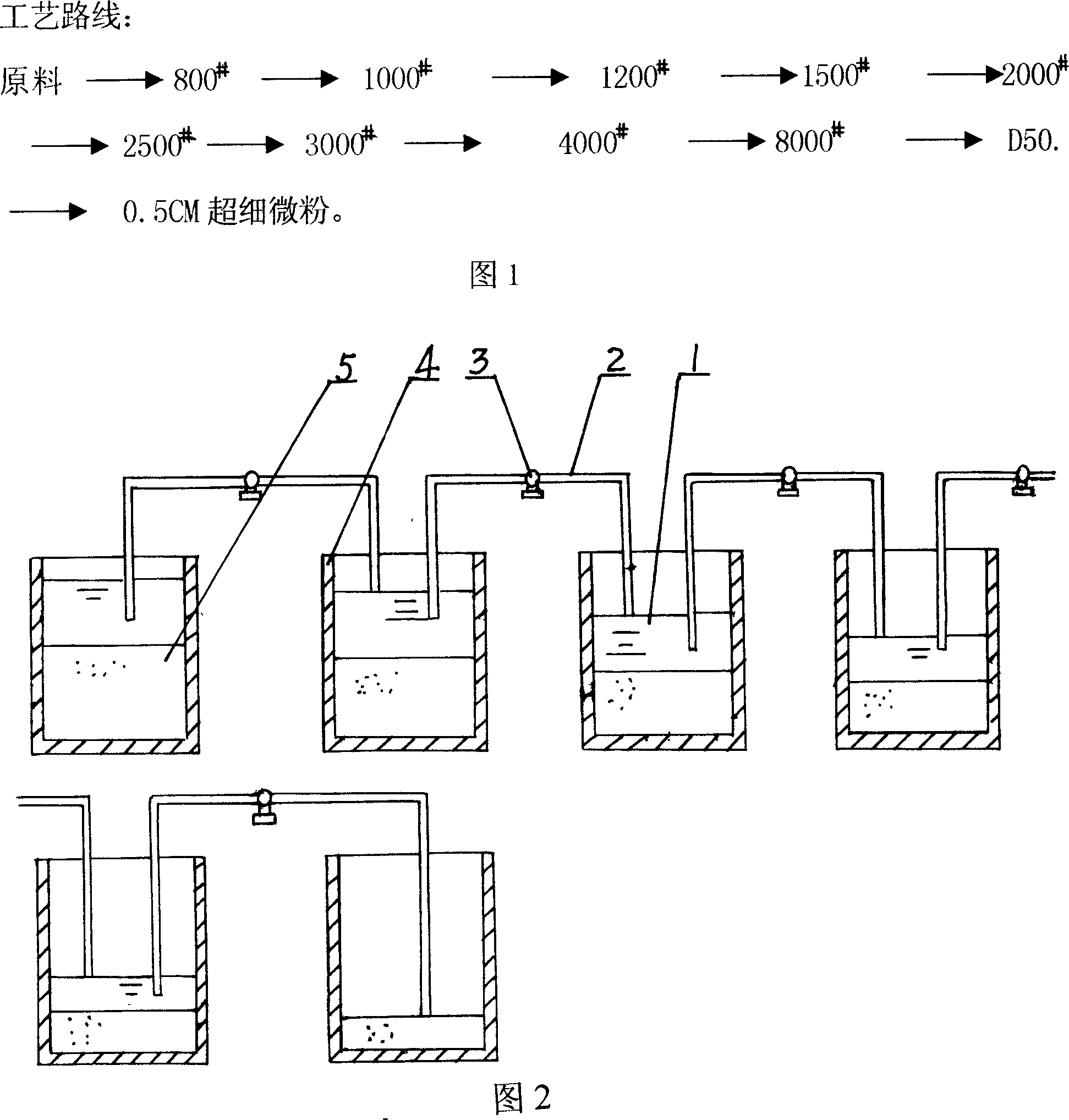

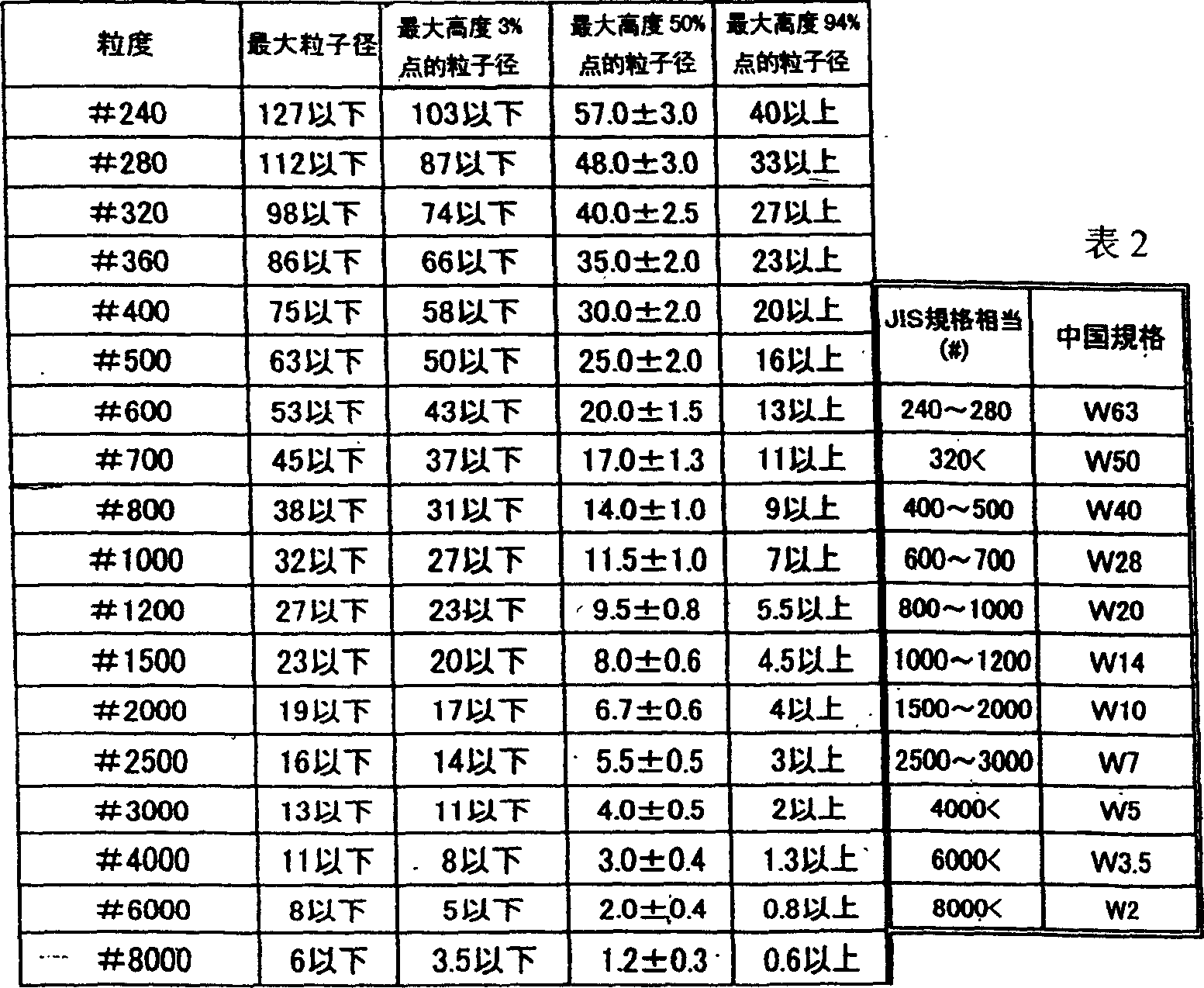

Method used

Image

Examples

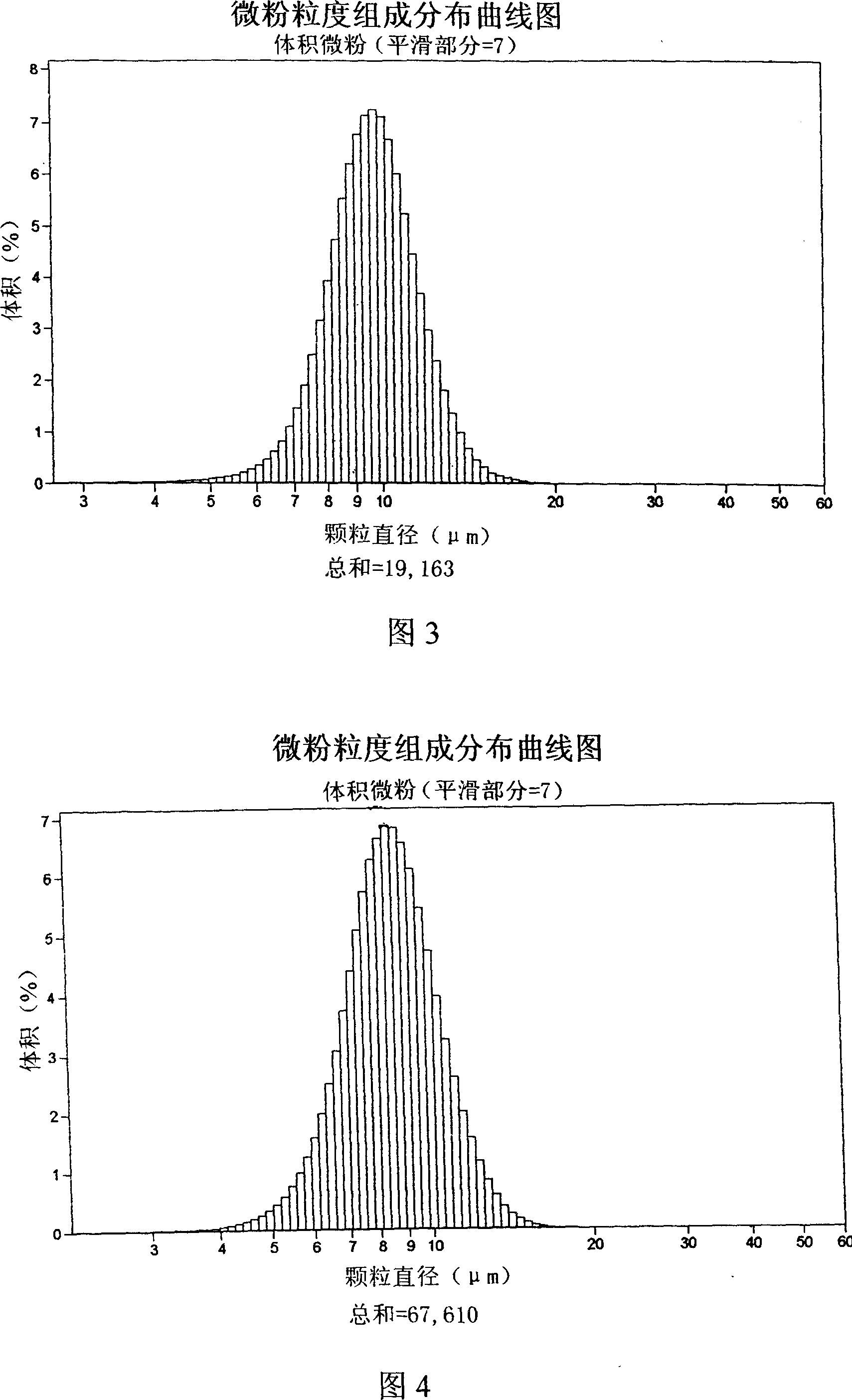

Embodiment 1

[0021] There are 6 tanks 4 with a diameter of 2.3 meters and a height of 0.8 meters. The tanks 4 are connected with each other with a conduit 2 , and the pump 3 on the conduit 2 guides the slurry 1 into the next tank 4 . Ion precipitation method is adopted; firstly, in neutral deionized water with conductivity < 100, add silicon carbide micropowder with a median diameter of 10 μ ± 0.5, the polymer dispersant is 3% of silicon carbide micropowder, and the concentration of mixed slurry 1 is 45% in turn Setting, the height of the slurry 1 in the tank 4 is 800CM, after stirring the slurry 1 for 10 minutes, get the slurry 1 at the bottom of the tank 4 (which is the sediment 5, which is the product); The fine powder of No. 1 is washed twice to achieve the product with the required fine powder particle size.

[0022] Chemical Composition Table 1

[0023]

Variety

Al2O3

SiO2

FeO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com