Automatic checking device of elevator and automatic checking method

A technology of automatic inspection and detection device, applied in the direction of transportation, packaging, elevators, etc., can solve the problems of difficult adjustment and false detection, and achieve the effect of reducing the cost of the device, preventing false detection, and reliable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

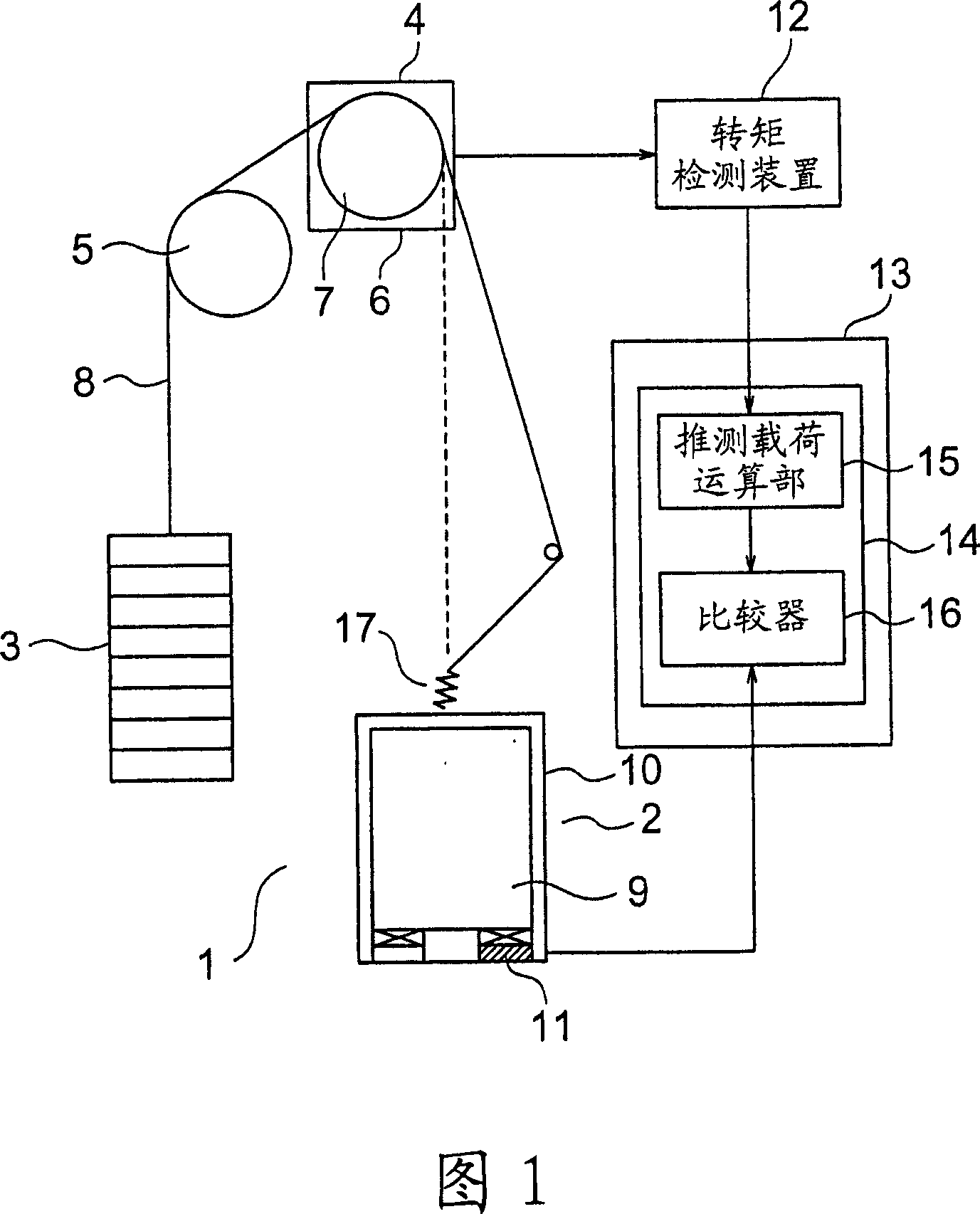

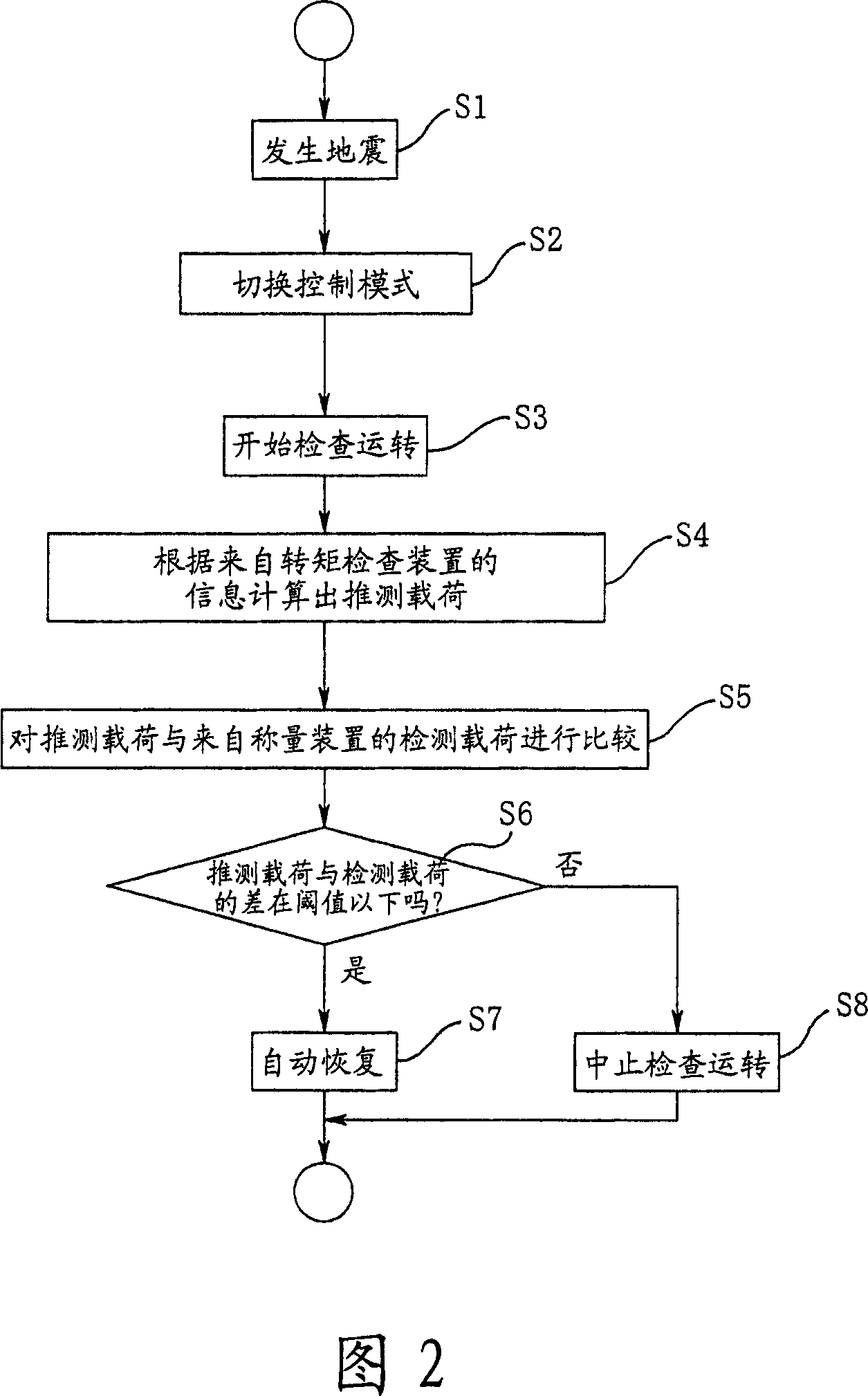

[0017] Fig. 1 is a block diagram showing an elevator provided with an automatic inspection device according to Embodiment 1 of the present invention. In FIG. 1 , a hoistway 1 is provided with a liftable car 2 and a counterweight 3 . On the upper part of the hoistway 1, there are: a traction machine (driver) 4 for lifting the car 2 and the counterweight 3; and a deflector pulley 5 .

[0018] The hoisting machine 4 has: a hoisting machine main body 6 including a motor; and a driving sheave 7 rotated by the hoisting machine main body 6 . A plurality of main ropes 8 are wound around the drive sheave 7 and the deflection sheave 5 . One end of each main rope 8 is connected to the upper portion of the car 2 , and the other end of each main rope 8 is connected to the upper portion of the counterweight 3 . The car 2 and the counterweight 3 are suspended in the hoistway 1 by respective main ropes 8 .

[0019] The car 2 has: a car chamber 9; and a car frame 10 that supports the car ch...

Embodiment approach 2

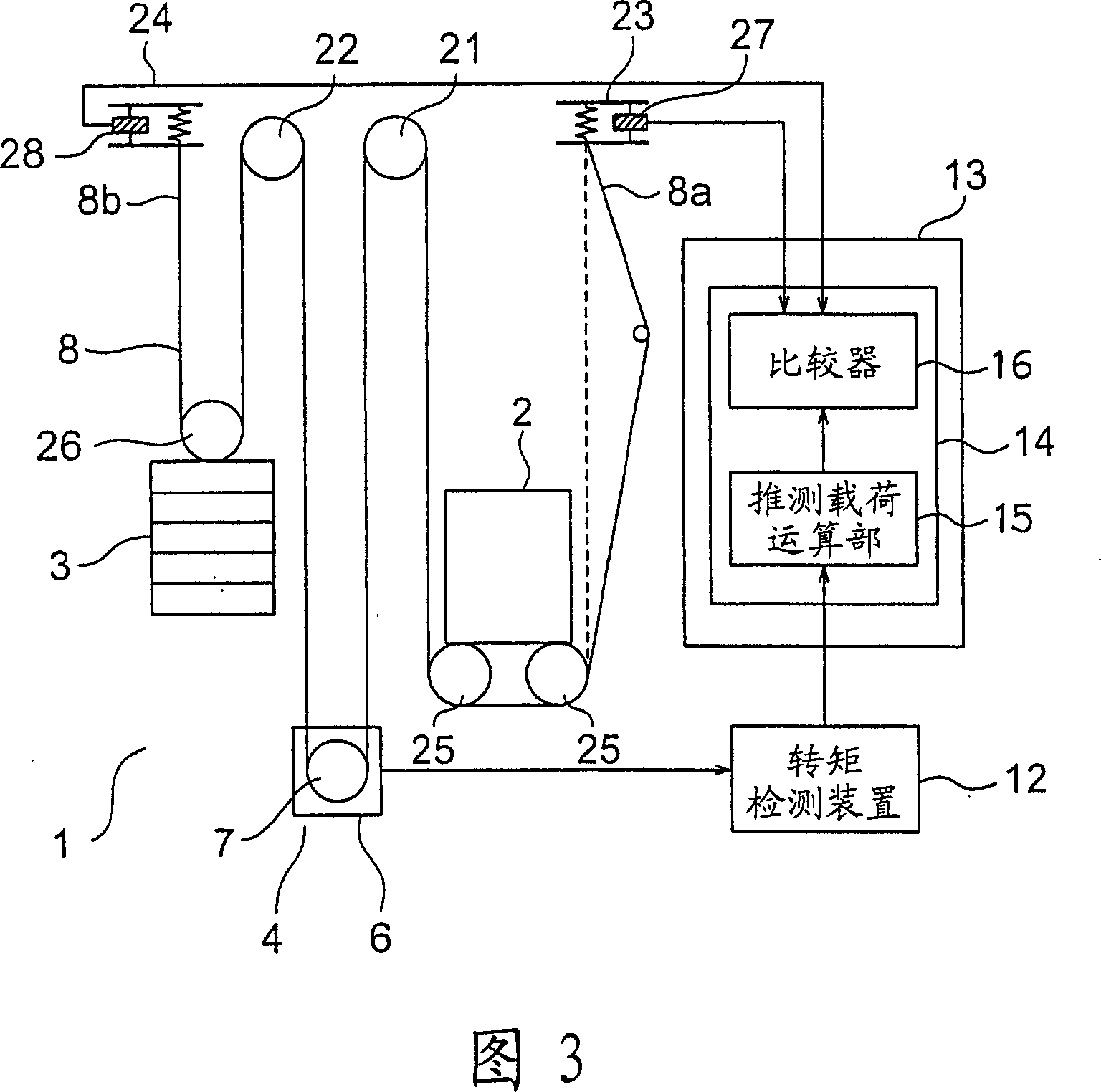

[0037] Fig. 3 is a block diagram showing an elevator provided with an automatic inspection device according to Embodiment 2 of the present invention. In the figure, the hoisting machine 4 is installed in the lower part of the hoistway 1 . A plurality of main ropes 8 are wound around the driving sheave 7 of the hoisting machine 4 . The car 2 and the counterweight 3 are suspended by respective main ropes 8 .

[0038] In the upper part of the hoistway 1, a car-side return sheave 21 and a counterweight-side return sheave 22 around which the main ropes 8 are respectively wound are provided. In addition, a first rope end device 23 connected to one end 8 a of each main rope 8 , and a second rope end device 24 connected to the other end 8 b of each main rope 8 are provided in the upper part of the hoistway 1 .

[0039] A pair of car hanging sheaves 25 are provided at the lower portion of the car 2 . In addition, a counterweight suspension wheel 26 is provided on the upper portion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com