Centrifugal pump having extrusion chamber with subchannel

A technology of shunt channels and pressure chambers, which is applied to parts, pumps, and pump components of elastic fluid pumping devices, can solve problems such as prolonged friction time, reduced flow efficiency, unfavorable safety, and environmentally friendly operation, and achieves The effect of reducing and shortening friction opportunities and time, improving flow efficiency, and reducing cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

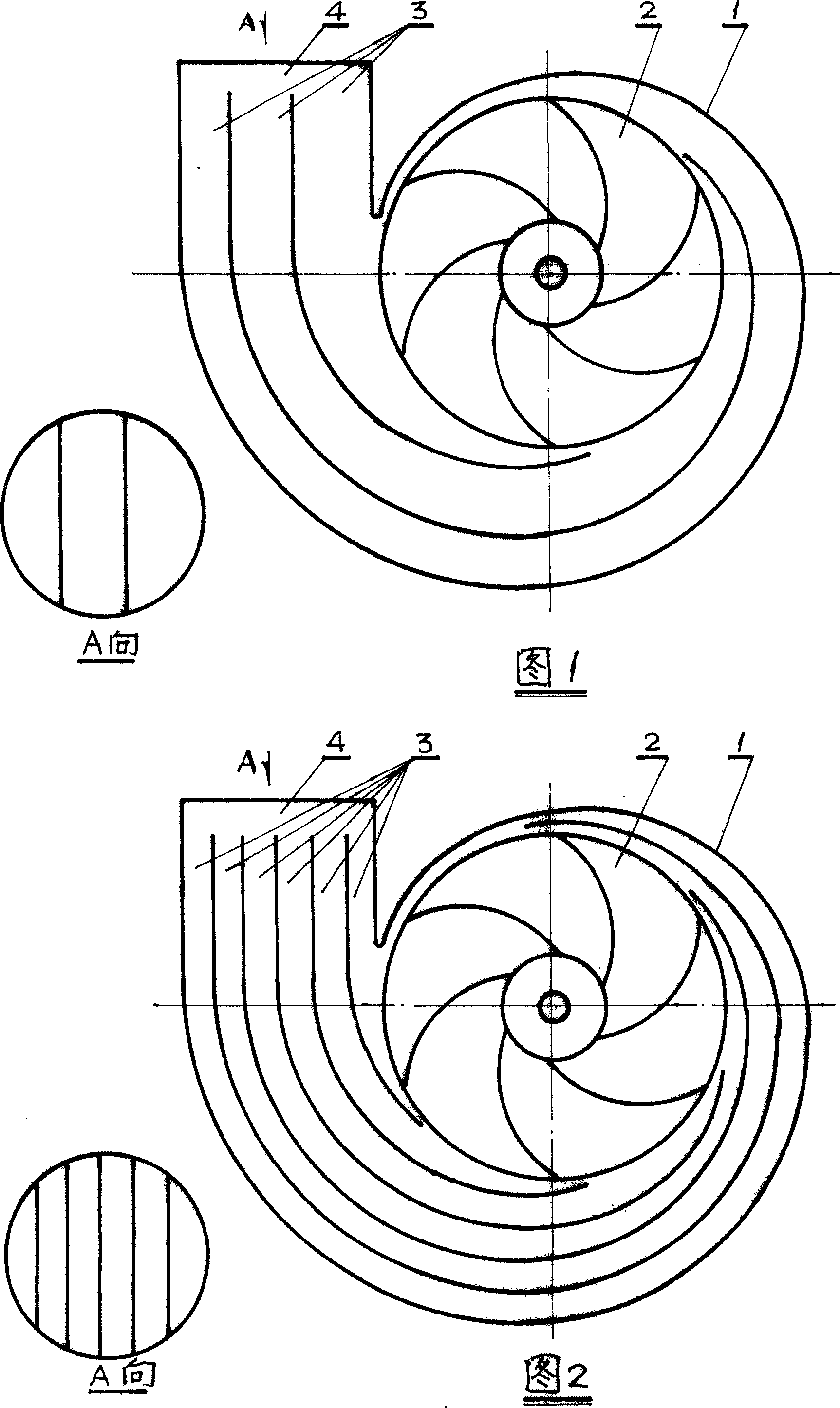

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] In the figure, the extrusion chamber in the extrusion chamber shell 1 has been occupied by the flow channel 3, and the arrangement of the flow channel 3 presents a center-symmetrical arrangement centered on the center of the impeller, and the liquid flow thrown out of the flow channel of the impeller 2 is timely It is introduced into the sub-flow channel 3 and flows into the main flow channel 4 smoothly. As for the number of shunt channels 3, the more the shunt, the more obvious the shunt effect, but it will increase the difficulty of the manufacturing process, so three to six are more suitable. For the manufacturing process of the flow channel 3, whether it is cast together with the pump casing's extrusion chamber or embedded after it is manufactured separately, the wall of the flow channel should be smooth to reduce the resistance along the process. Most of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com