Sludge pump and its operation method

An operation method and sludge technology, applied in the direction of pumps, pump control, liquid variable capacity machinery, etc., can solve problems such as high cost, many construction equipment, and subsidence of the working face, and achieve low labor intensity, high degree of intelligence, and Reduces the effect of hydraulic shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

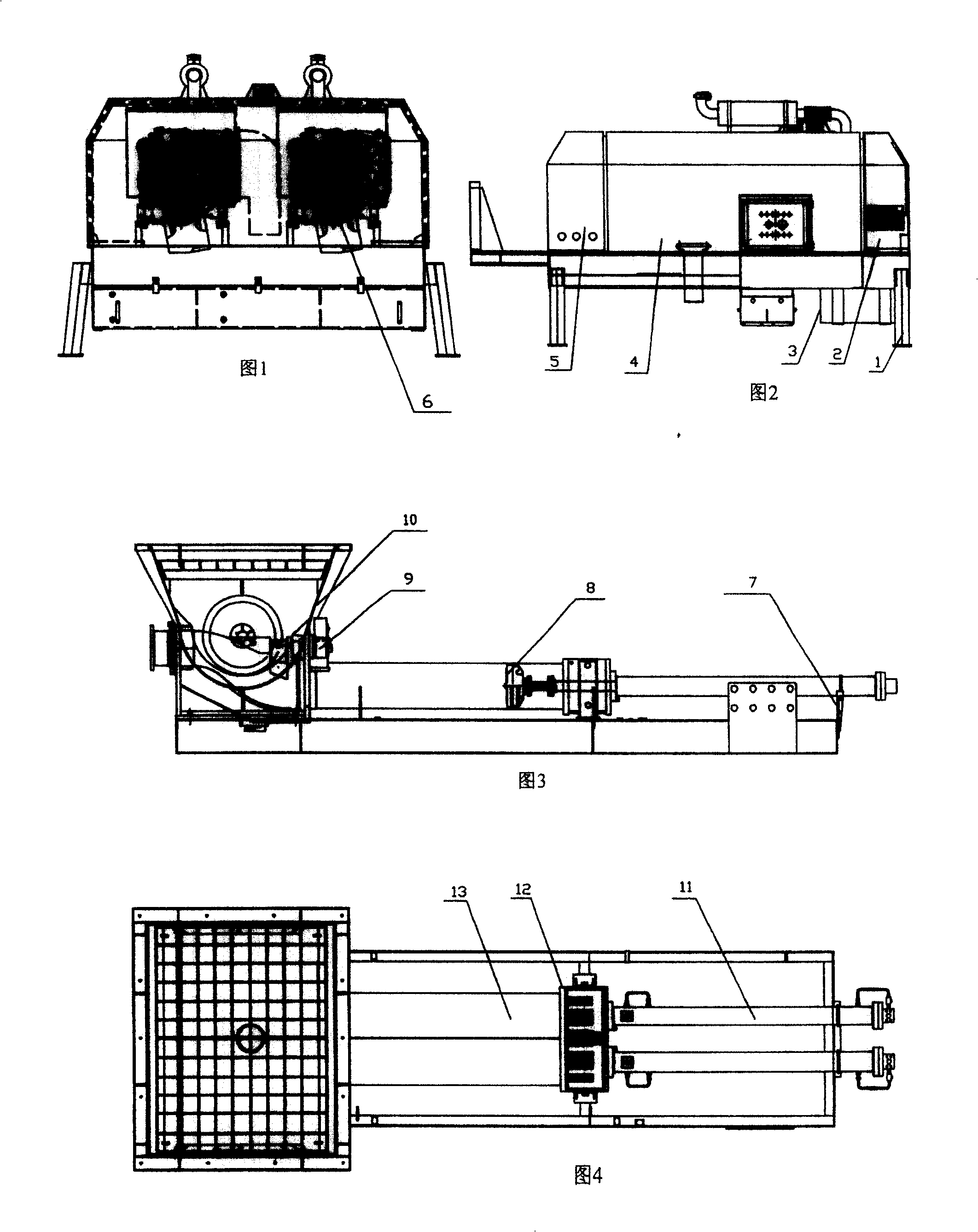

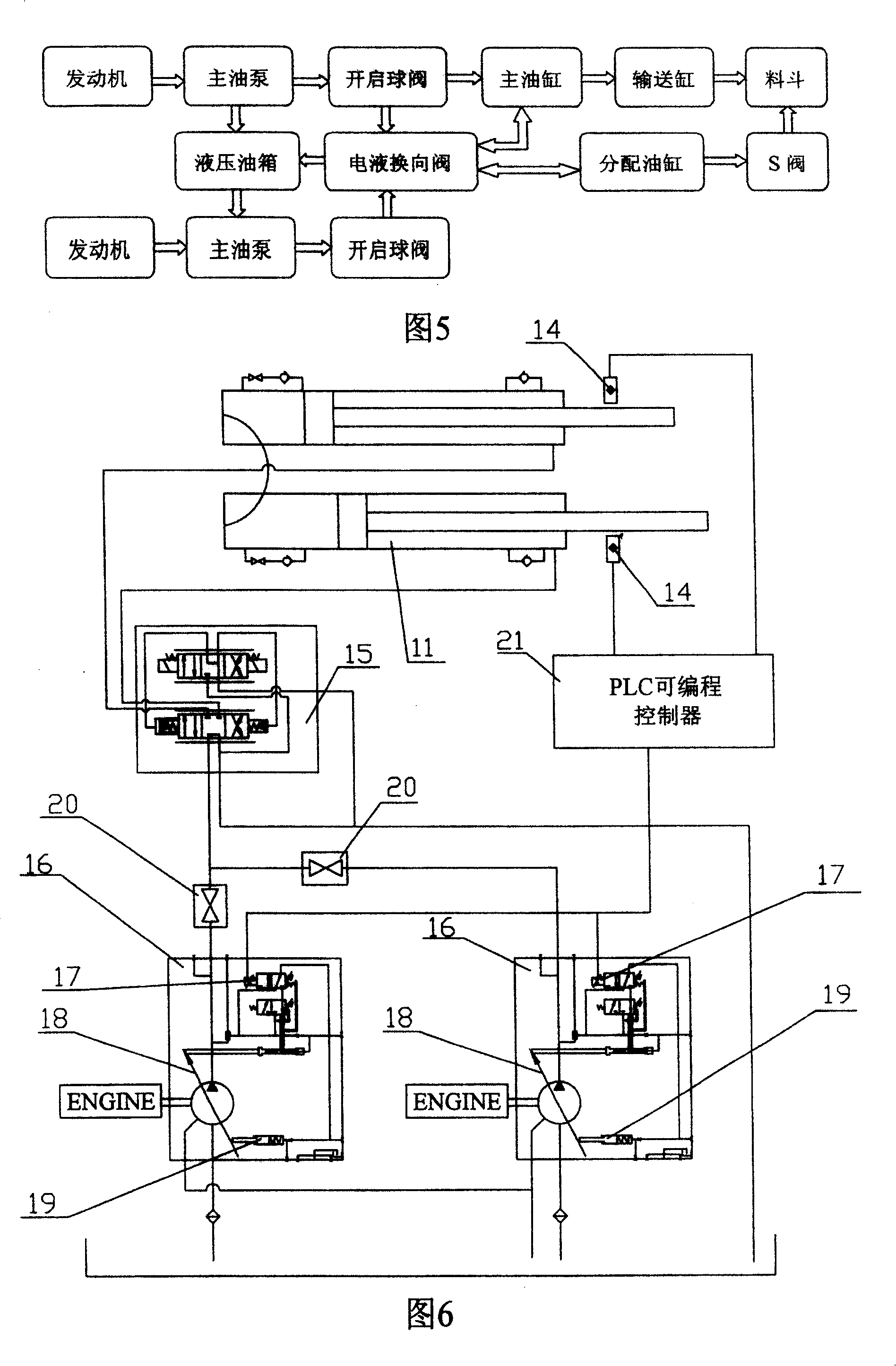

[0015] Sludge pump technology, in terms of its structure and performance, is mainly divided into three parts: pumping system, hydraulic system and electrical system.

[0016] The pumping system of the present invention adopts dual power to drive the hydraulic oil pump group separately, so that the pumping work is stronger and the system is more reliable. The electrical system adopts PLC programmable control system, which prolongs the trouble-free working time. The hydraulic system is equipped with double safety devices of main oil pump pressure cut-off and safety valve. Effectively improve the reliability of the whole machine. The present invention takes the MPS330 sludge pump as an example.

[0017] According to accompanying drawings 1, 2, 3, 4, the power unit of the sludge pump of the present invention is relatively independent from the pumping system, and the two parts are connected by hydraulic pipelines. The power device of the sludge pump is composed of the chassis 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com