Lens barrel

A technology for lens barrels and components, applied in installation, television, optics, etc., can solve problems such as image jitter and image loss, and achieve the effects of simple mechanism, prevention of gear strength reduction, and smooth rotation operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

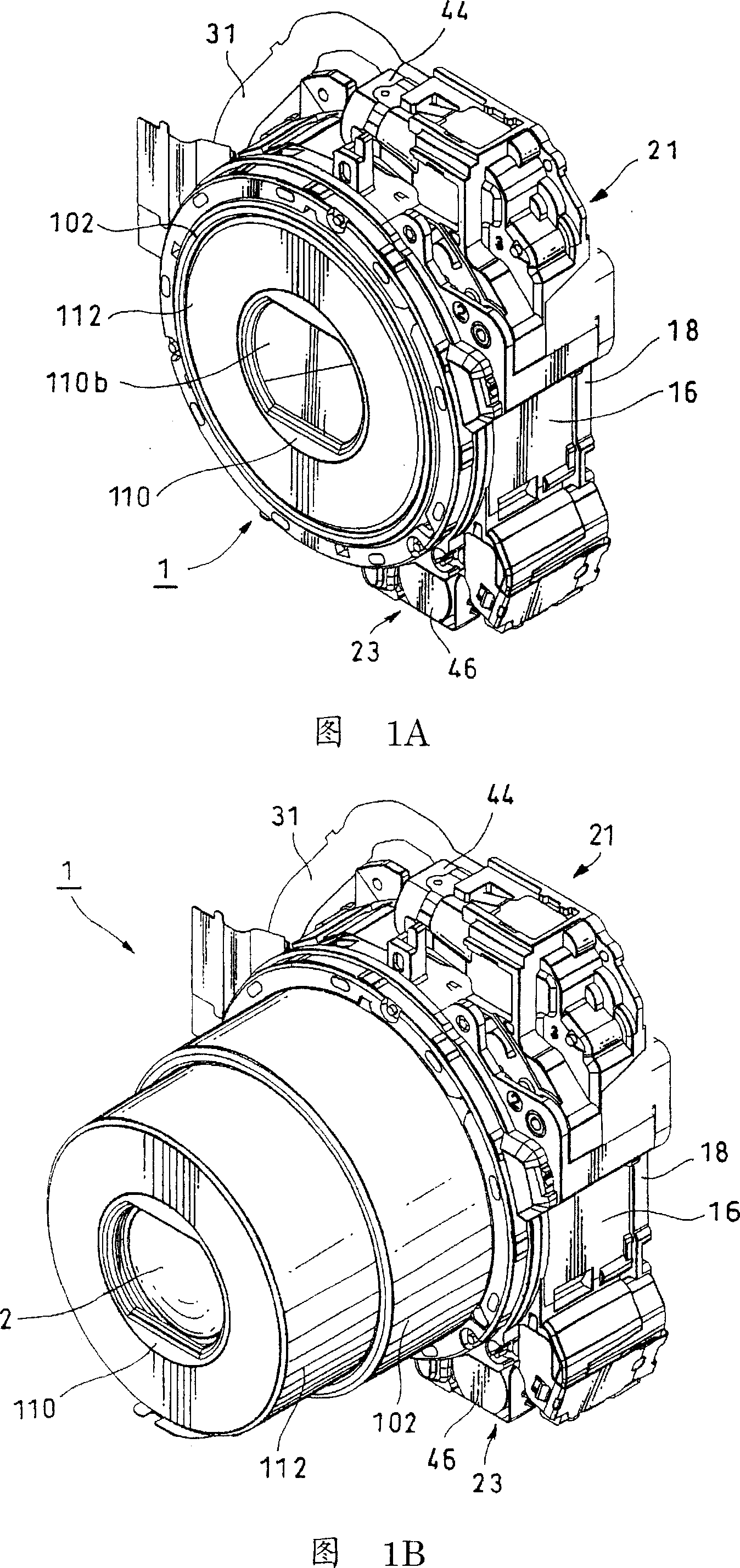

[0048] According to the present invention, there is provided a lens barrel in which maintaining smooth rotational operation of a rotating member makes it possible to suppress image loss, image shake, and occurrence of abnormal sound (noise) generated when operating the lens barrel.

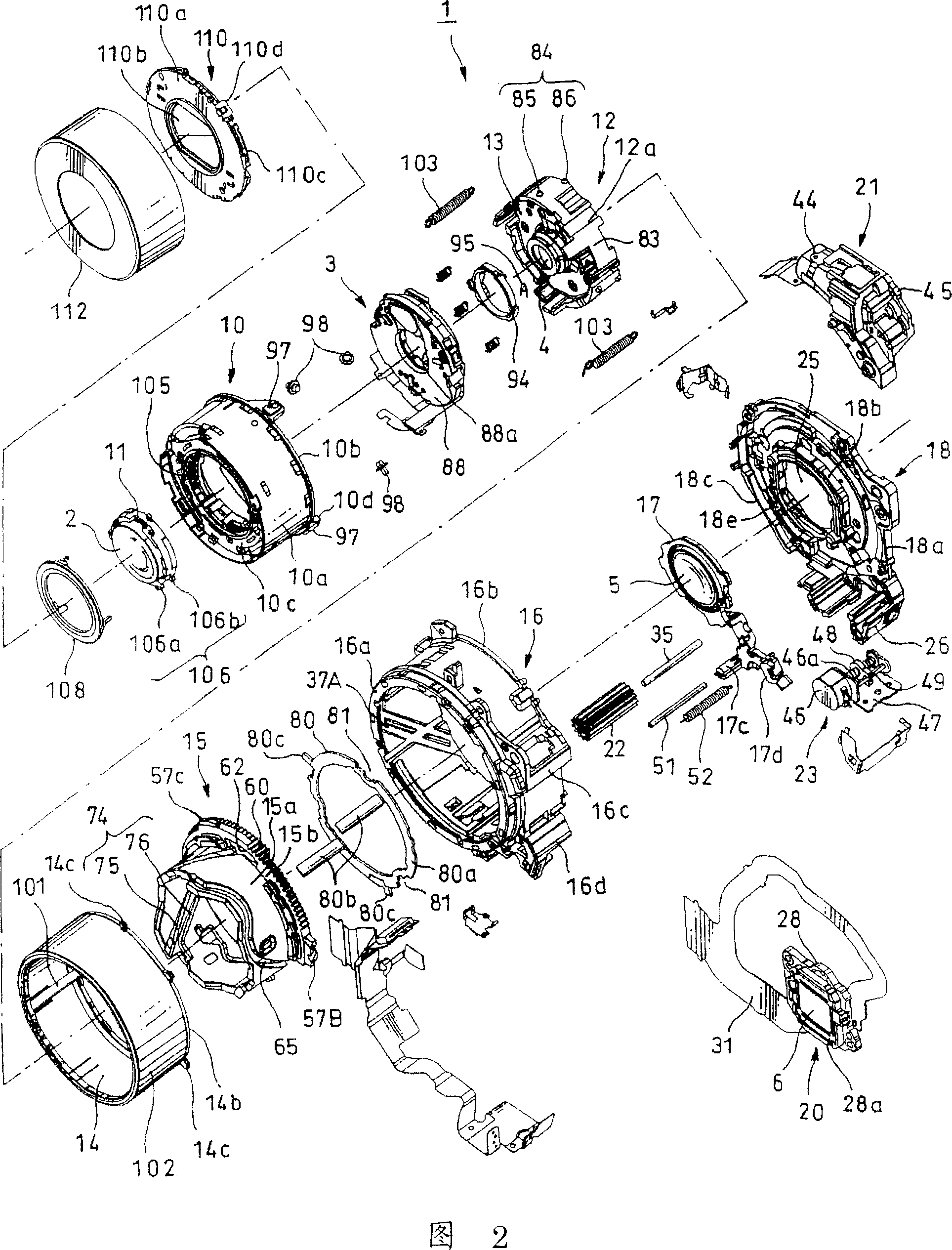

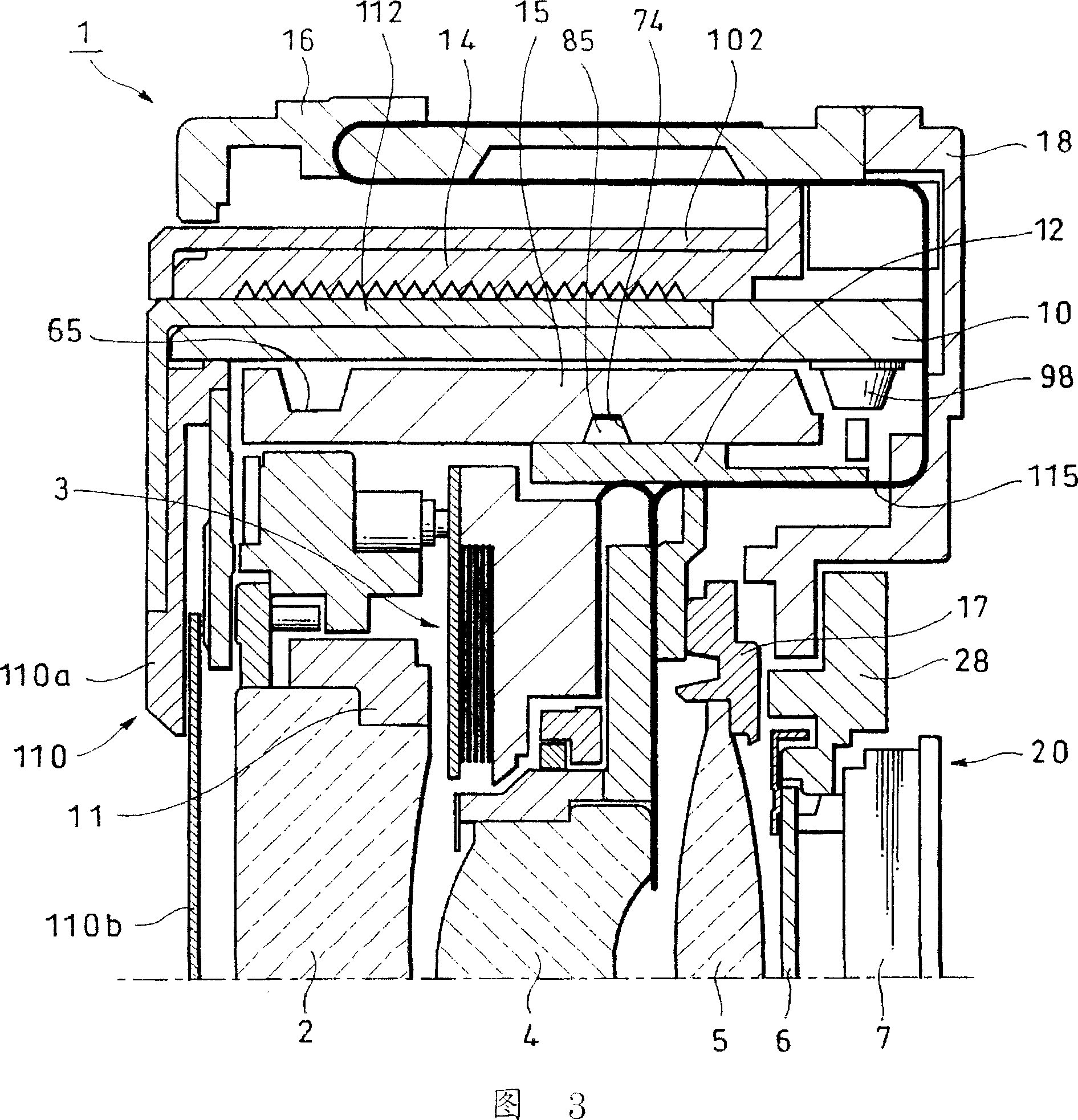

[0049] Embodiments of the present invention will be described below with reference to the drawings. 1A, 1B to 37 are diagrams for explaining an embodiment of the present invention. More specifically, FIGS. 1A and 1B are perspective views showing a first embodiment of the lens barrel cam mechanism according to the present invention, respectively, wherein FIG. 1A shows the retracted state of the lens barrel, and FIG. 1B shows the extended state of the lens barrel. . Fig. 2 is an exploded perspective view of the lens barrel shown in Figs. 1A and 1B. Fig. 3 is a sectional view showing a retracted state of the lens barrel. Fig. 4 is a sectional view showing a state in which the lens barrel is extend...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap