Slotless modular wind-driven generator of breeze

A wind turbine, building block technology, used in wind power generation, synchronous motors with static armatures and rotating magnets, synchronous machine parts, etc., can solve the problem of high starting torque and starting wind speed, and it is difficult to reduce the size between windings , poor stability and other problems, to achieve the effect of small starting torque, reducing starting torque and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

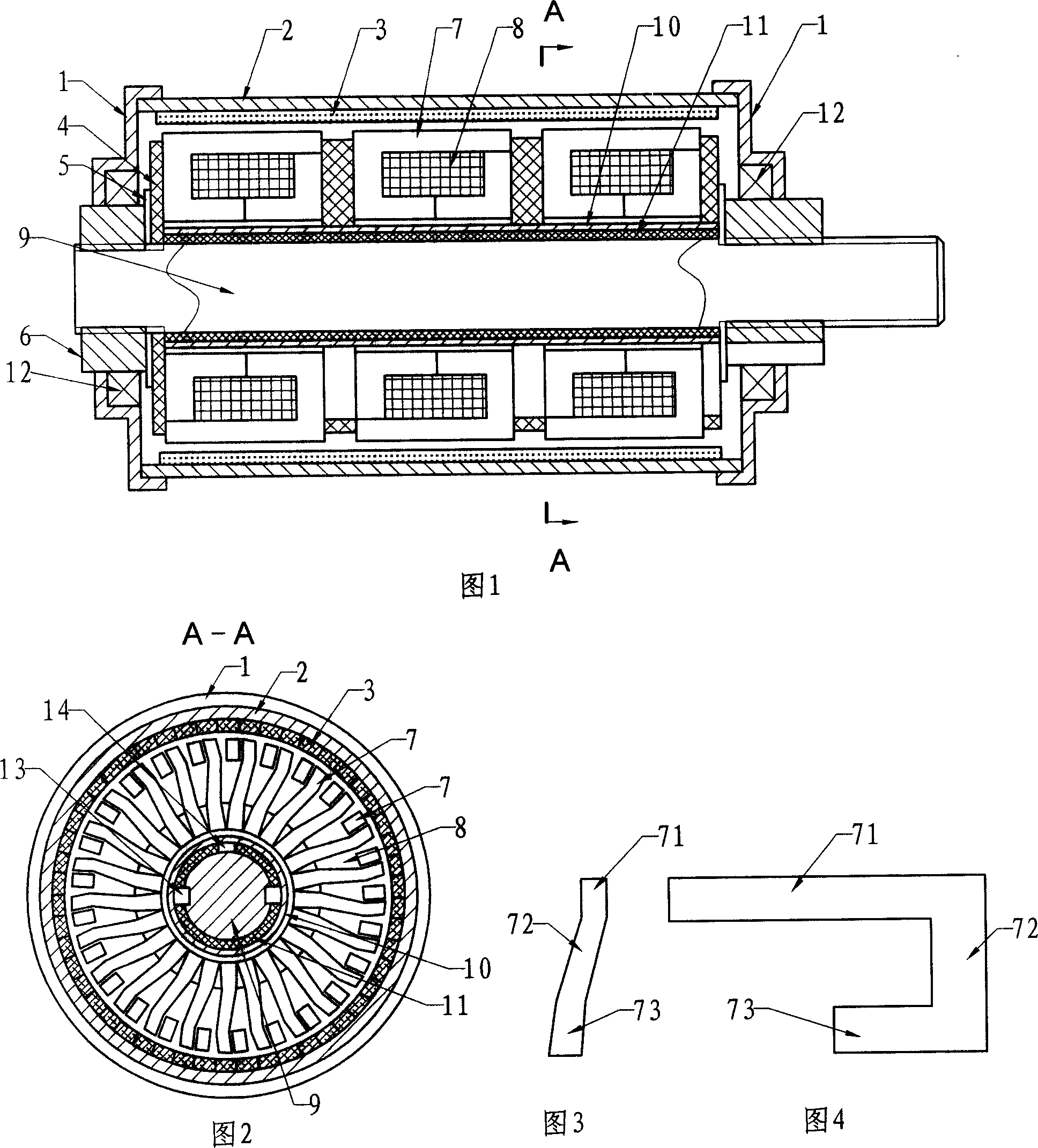

[0022] As shown in Figure 1 and Figure 2.

[0023] The slotless building block breeze wind generator includes two main parts, the stator and the rotor.

[0024] In the middle of the stator is a central shaft 9 fixed on the machine base, and three groups of iron cores and coil windings are nested on the central shaft 9 in sequence, and each iron core and coil windings are provided at both ends. The insulating positioning partition 4, the coil 8 is radially wound in the I-shaped groove of the hollow I-shaped coil frame (not shown in the figure), and the two end faces of the coil frame are provided with radial radial grooves, which are stuck in the coil frame The iron core 7 in the radial radial groove is composed of two J-shaped silicon steel sheets. As Fig. 3, Fig. 4, described silicon steel sheet is J type, by silicon steel sheet outer side 71, silicon steel sheet middle part 72 and silicon steel sheet inner side 73, silicon steel sheet outer side 71 and silicon steel sheet i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com