Polyamide moulding compositions with improved flowability

A molding composition, thermoplastic polyamide technology, applied in the field of polyamide molding compositions with improved fluidity, capable of solving problems such as increased melt viscosity

Active Publication Date: 2011-04-27

LANXESS DEUTDCHLAND GMBH

View PDF34 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It is highlighted that the use of acrylate-modified polyolefins results in an increase in melt viscosity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

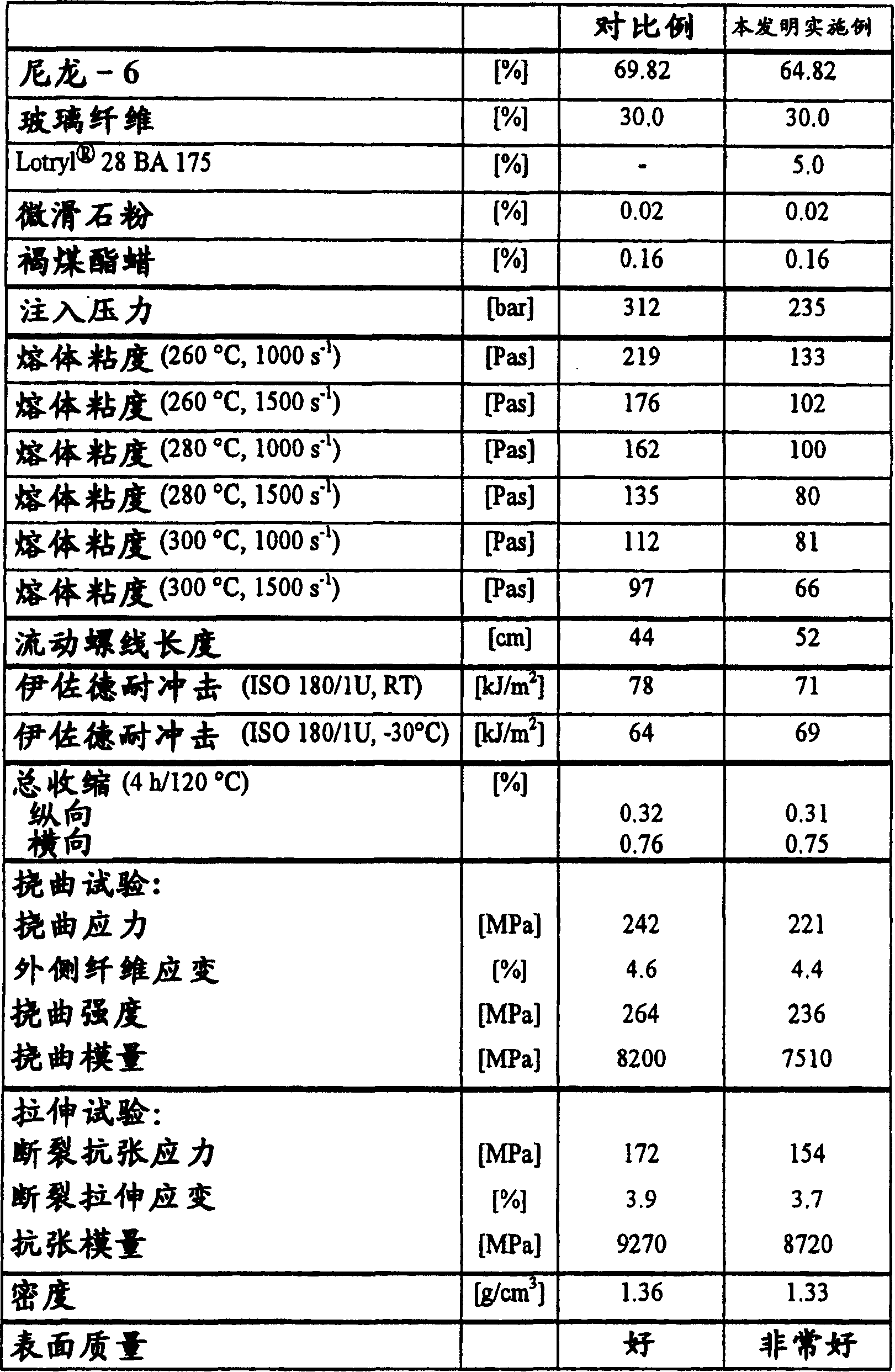

Embodiment

[0135] Use the following:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to a thermoplastic polyester and olefin-alkyl (meth)acrylate copolymer with high melt flow index, in which the thermoplastic polyeste contains a alpha-alkene and at least one of (meth)acrylate(s) with 1-4C aliphatic alcohols showing a melt flow index(MFI) of not less than 50 g / 10 min. The present invention also relates to a method of preparing the thermoplastic polyester and to the use of the thermoplastic moulding material in electric, electrical, telecom, motor or computer industries, and model piece application in gym, domestic appliance, medicine or entertainment industries.

Description

technical field [0001] The present invention relates to molding compositions based on at least one semi-crystalline thermoplastic polyamide and at least one copolymer, wherein the copolymer consists of at least one olefin, preferably an alpha-olefin, and at least one Atomic aliphatic alcohol methacrylate or acrylate composition, the MFI (melt flow index) of the copolymer is not less than 50g / 10min, also relates to the preparation method of such molding composition, and the use of such molding composition Applications for the production of molded parts or semi-finished products by injection molding or extrusion. Background technique [0002] High flow thermoplastic compositions are of interest in various fields of injection molding. For example, thin-walled parts in the electrical, electronics and automotive industries require thermoplastic compositions with low viscosity to allow the material to be injected into the mold of a suitable injection molding machine with minimal ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L77/00B29C45/26C08L33/06

CPCC08L77/06C08L33/08C08L33/10C08L77/02C08L77/00C08L2666/06C08L2666/04C08L79/02

Inventor D·乔奇米M·比恩穆勒J·恩德特纳R·乌尔里奇P·帕斯格哈尔S·克林根霍弗

Owner LANXESS DEUTDCHLAND GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com