Laser diode control circuit loop

一种激光二极管、控制回路的技术,应用在激光器、激光器零部件、半导体激光器等方向,能够解决无法符合需求、激光二极管无法正常工作等问题,达到成品率高、消耗功率少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

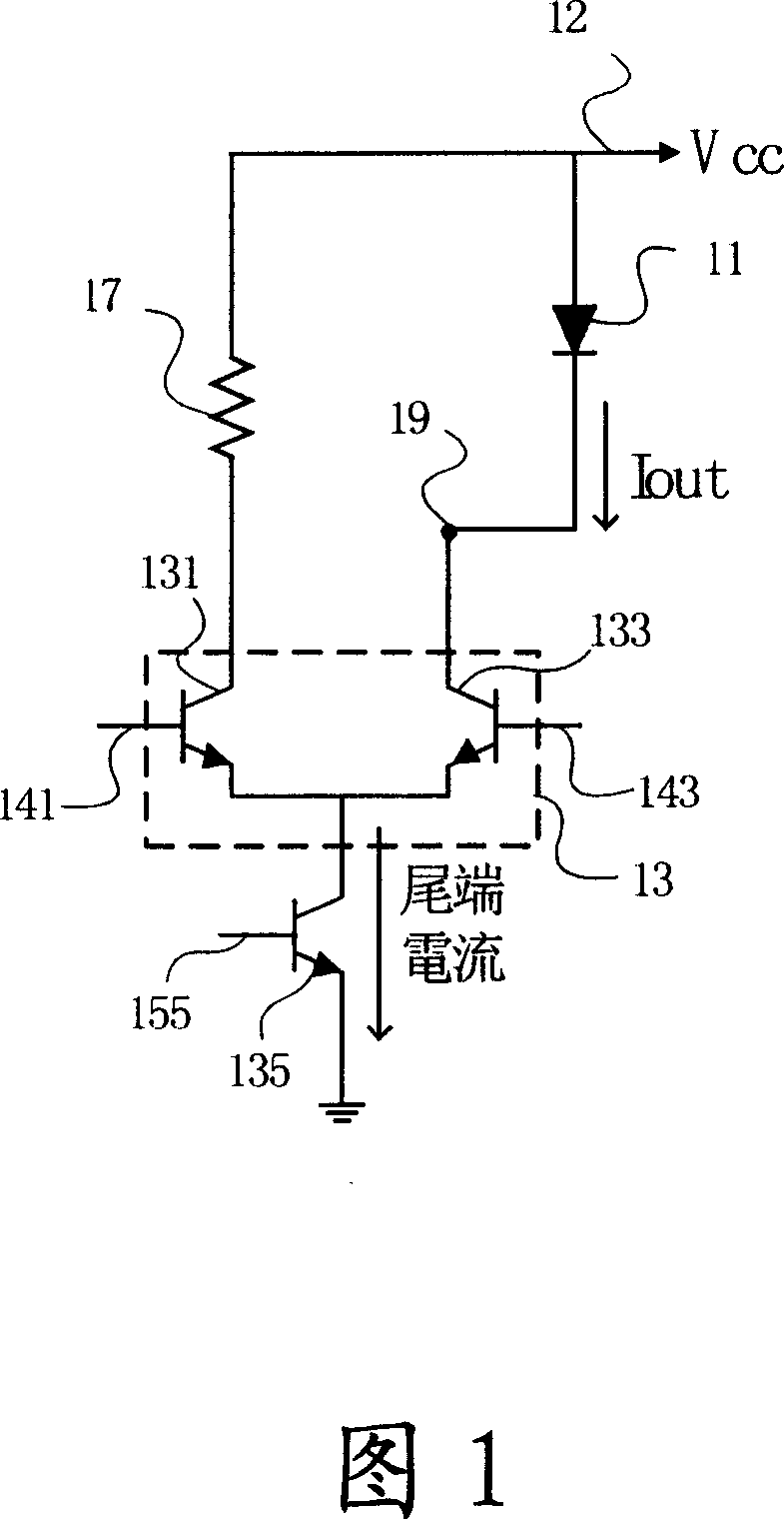

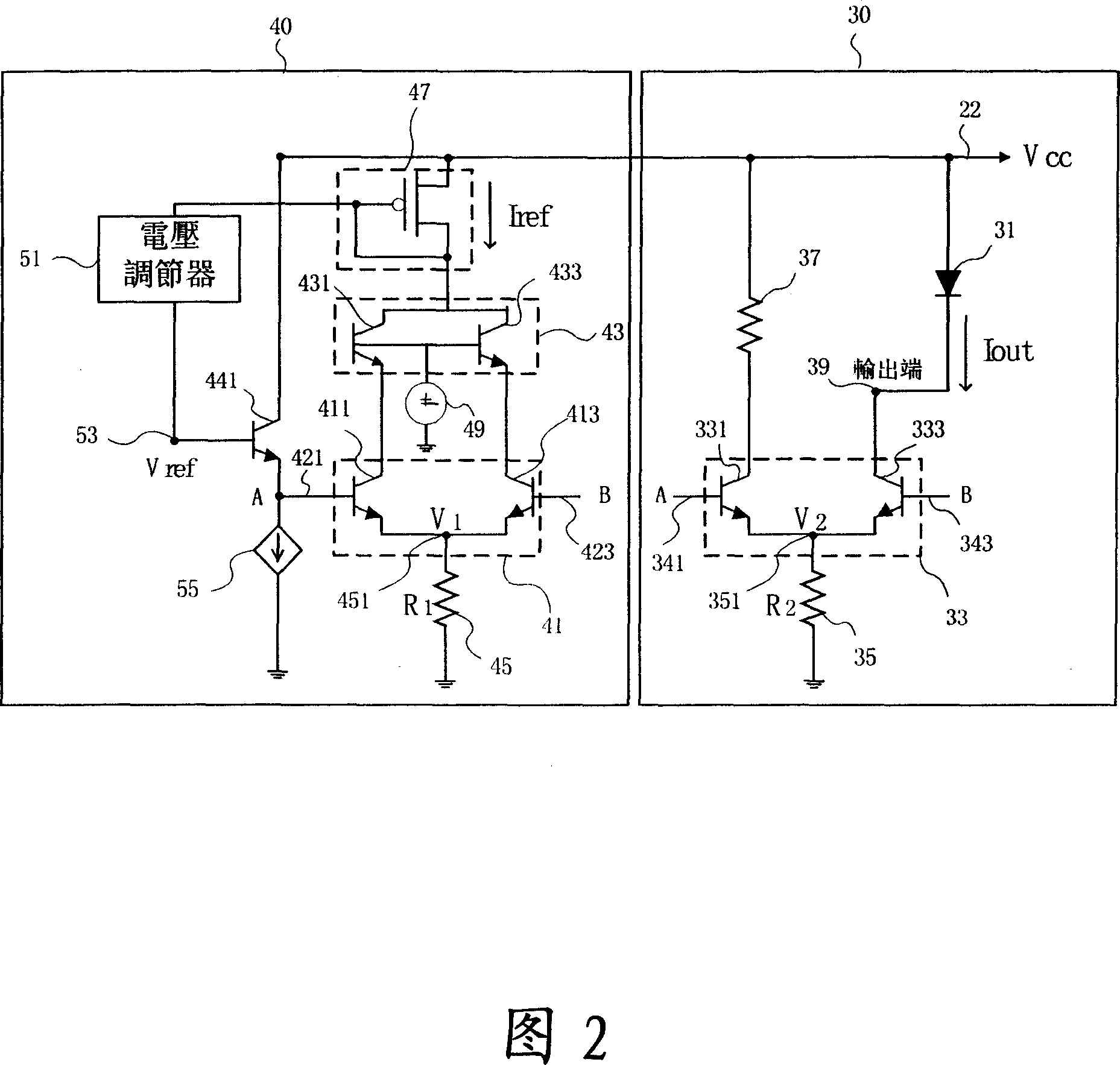

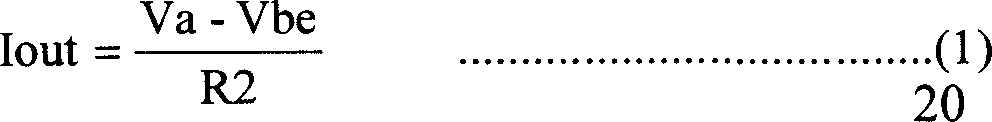

[0019] First, please refer to FIG. 2, which is a circuit diagram of a preferred embodiment of the present invention. As shown in the figure, the control loop 20 of the laser diode of the present invention mainly includes a reference circuit 40 and a driving circuit 30.

[0020] The reference circuit 40 has a programmable reference current Iref, and the reference current Iref is generated by a current source switch unit 47. The current source switch unit 47 can be a P-type MOSFET. The gate terminal and the drain terminal are connected together, and the source terminal is connected with a supply voltage 22.

[0021] In addition to the current source switch unit 47, the reference circuit 40 further includes: a first high-speed switch unit 43, a second high-speed switch unit 41, an emitter follower 441, and a voltage regulator 51.

[0022] Among them, the second high-speed switch unit 41 includes a third transistor 411 and a fourth transistor 413. The third transistor 411 and the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com