Polynary control system for adding drugs automatically

An automatic dosing and control system technology, which is applied to mixers, mixer accessories, sedimentation and separation, etc., can solve the problems of insufficient accuracy, waste of medicines, and low work efficiency, so as to achieve accurate dosing of medicines and save the cost of medicines Increase and save running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

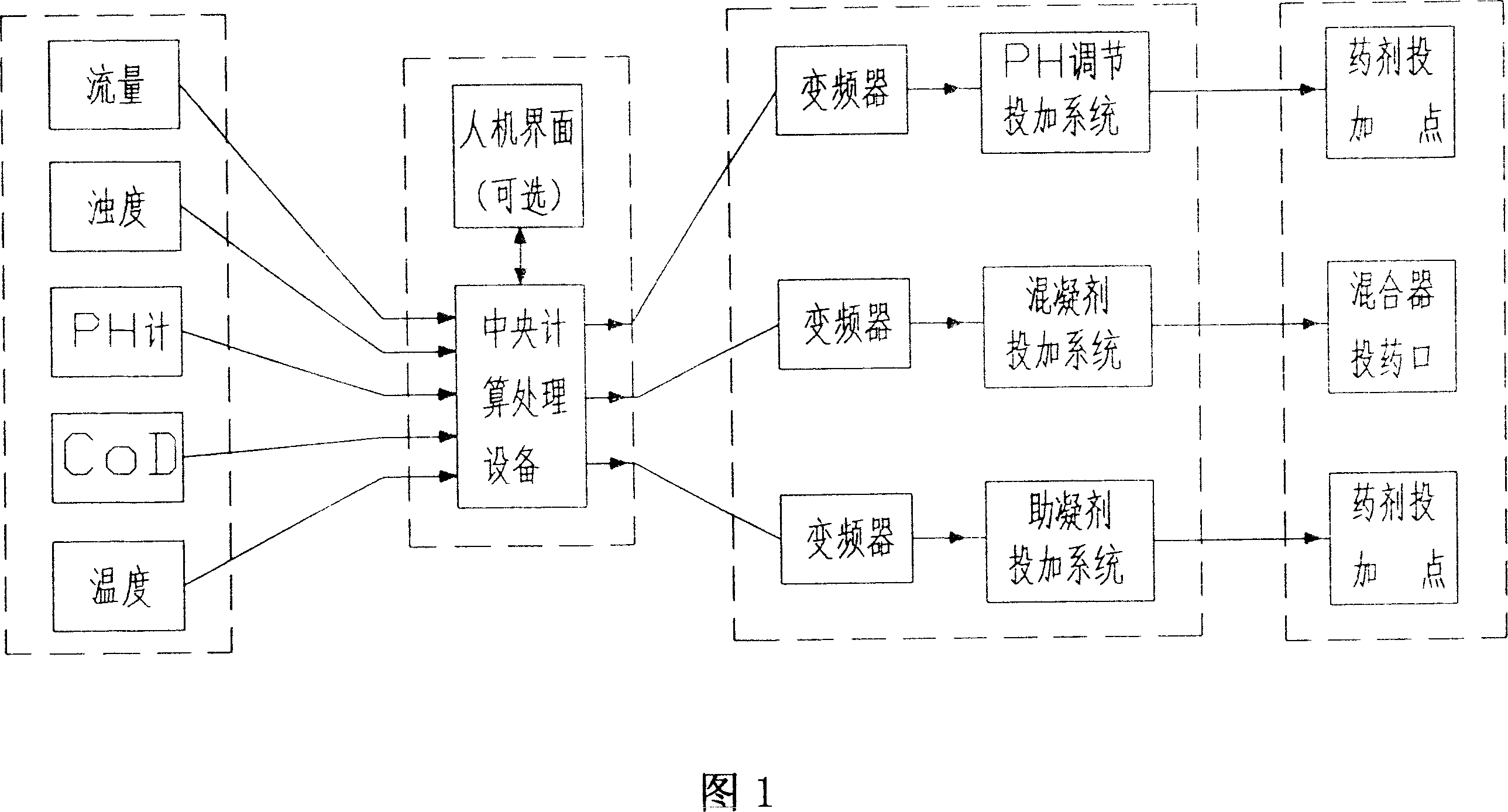

[0053] Establish a mathematical control model according to the role of water quality parameters in the control system:

[0054] 1. The standard 4-20mA current signal output by the online PH meter is sent to the central processing equipment. If the water treatment process has a conditioning function, the central processing equipment outputs a 0-10V or 4-20mA signal to control the frequency conversion dosage of the conditioning agent add. If the process equipment has no conditioning function, the 4-20mA signal of the pH meter will participate in the dosage control of the coagulant.

[0055] 2. According to the parameters collected by the raw water turbidity meter, COD, PH meter, temperature and other online instruments and the standard 4-20mA signal input to the central processing equipment, through the mathematical model calculation of the central processing equipment (using neural network, fitting, self-adaptive ) Determine the unit consumption of the dosing amount, collect a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com