Refractory steel of anti intercrystalline corrosion, and preparation method

A technology for intergranular corrosion and heat-resistant steel, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems such as inspection and failure to pass intergranular corrosion, achieve simple preparation process, eliminate intergranular corrosion, and design components reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

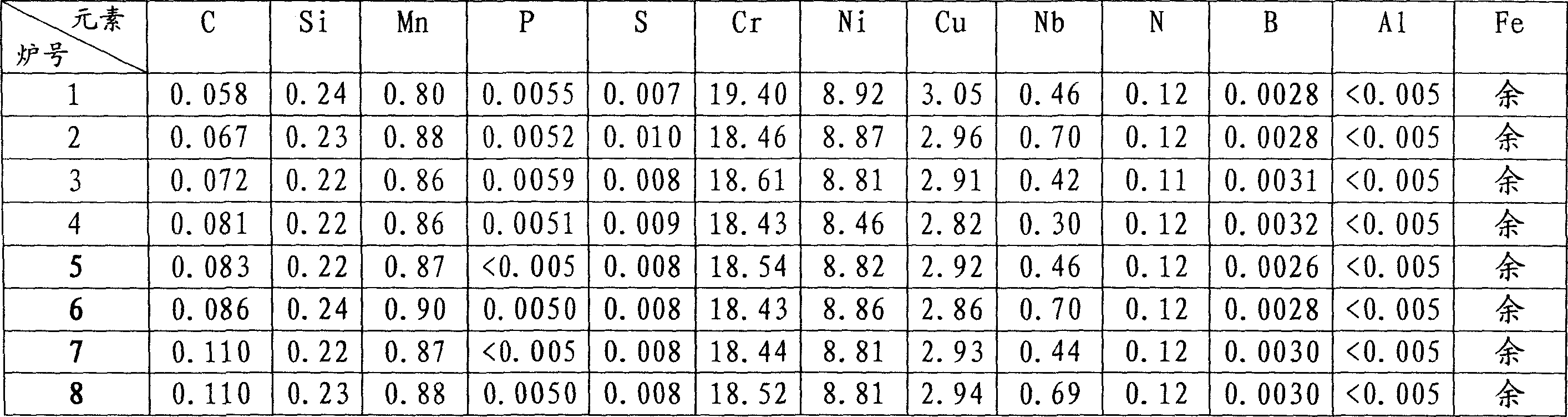

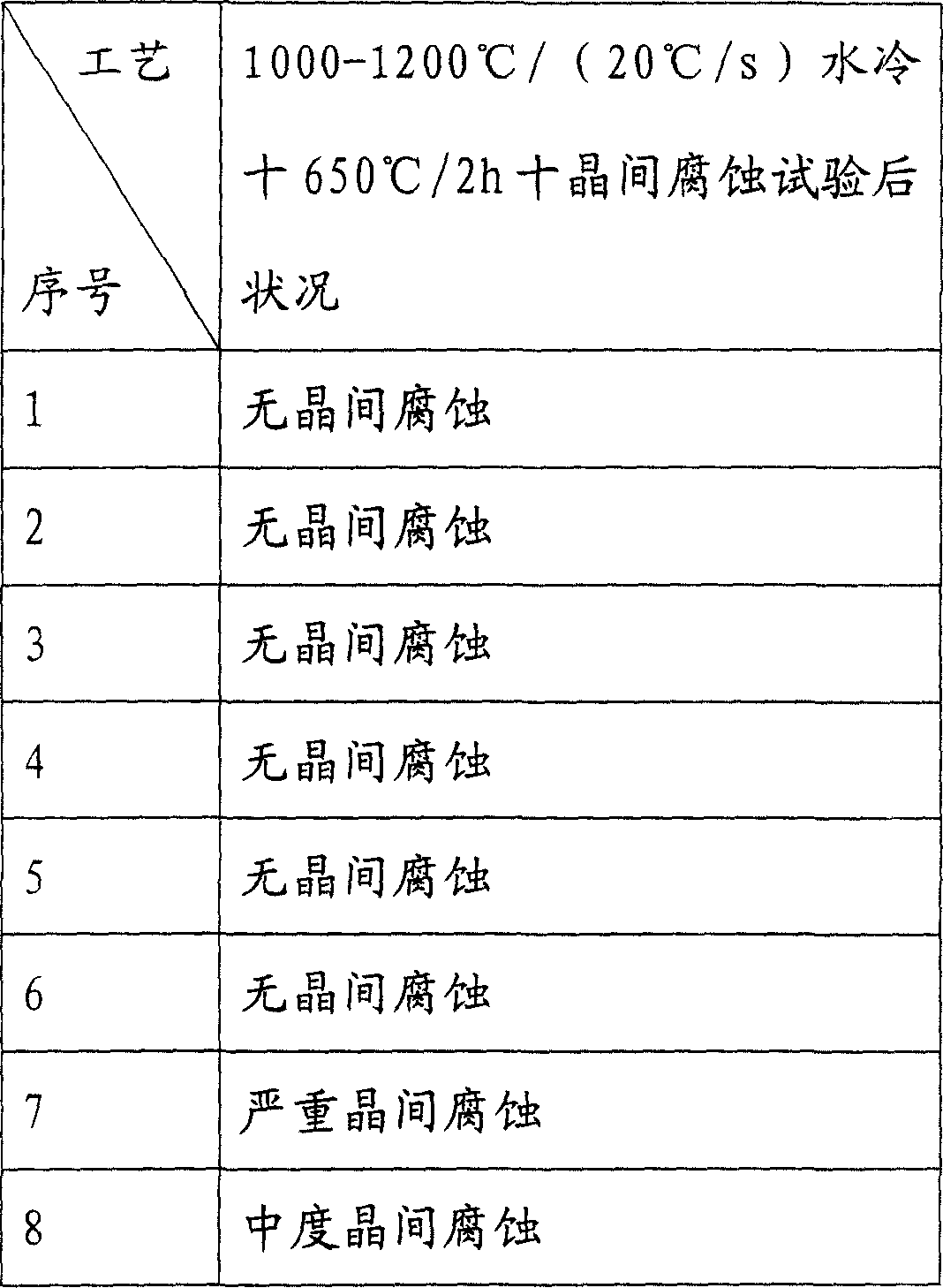

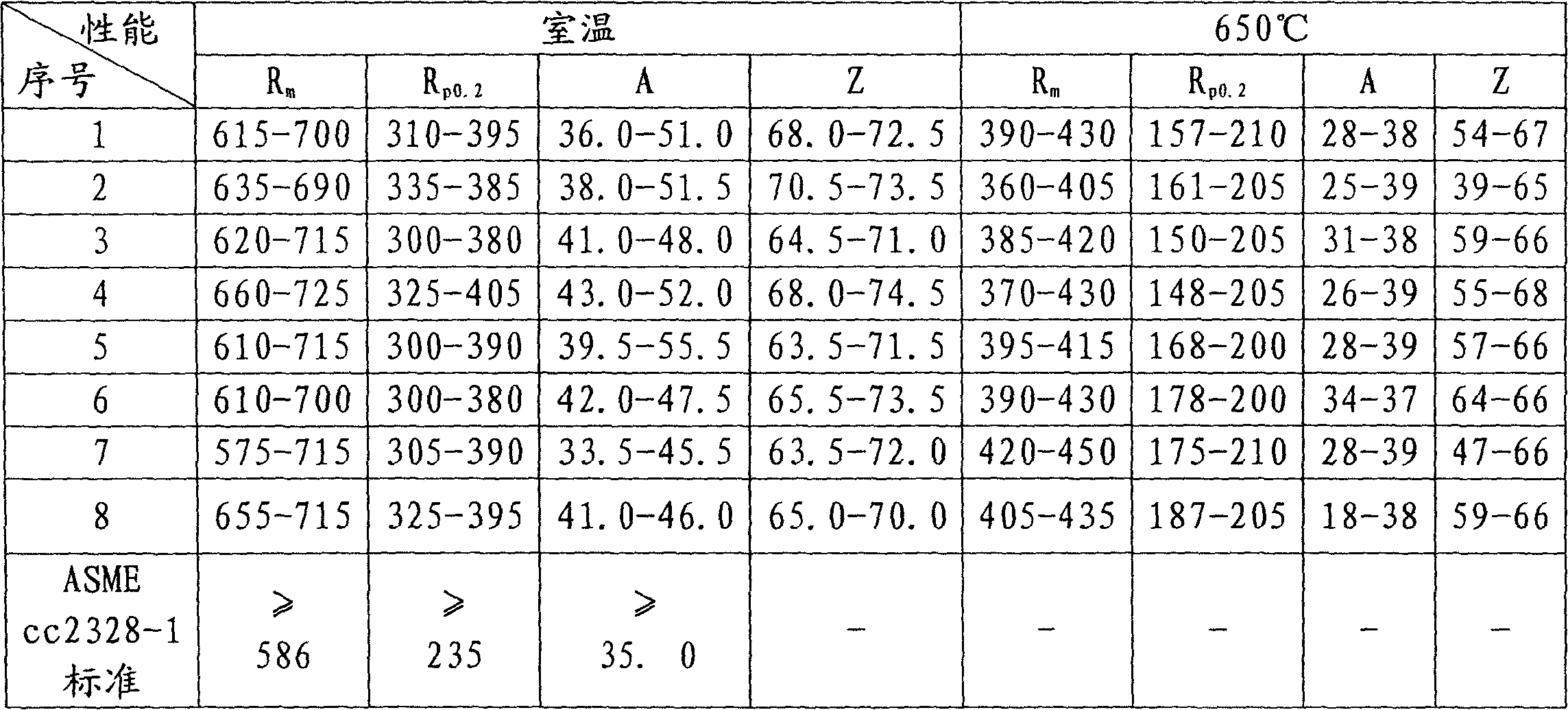

[0011] According to the anti-intergranular corrosion heat-resistant steel and its preparation method proposed by the present invention, we have done six sets of tests and two sets of comparative tests according to the composition range of the heat-resistant steel of the present invention. EXAMPLES Tests The production of heat-resistant steel is smelted by electric furnace, and then the steel ingot is forged at 1100°C, and the final forging temperature is higher than 900°C. Embodiment of the present invention compares result with prior art and all lists the following table. Table 1 is the comparison of the composition of the anti-intergranular corrosion heat-resistant steel of the embodiment of the present invention and the comparison steel S30432; Table 2 is the solid solution treatment process and intergranular corrosion test results of the anti-intergranular corrosion heat-resistant steel of the embodiment of the present invention; Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com