Method for fabricating lead frame of triode

A technology of lead frame and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of waste of electroplating energy costs, unstable quality control, and high production costs, so as to improve production efficiency and benefit quality The effect of controlling, reducing production costs and energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

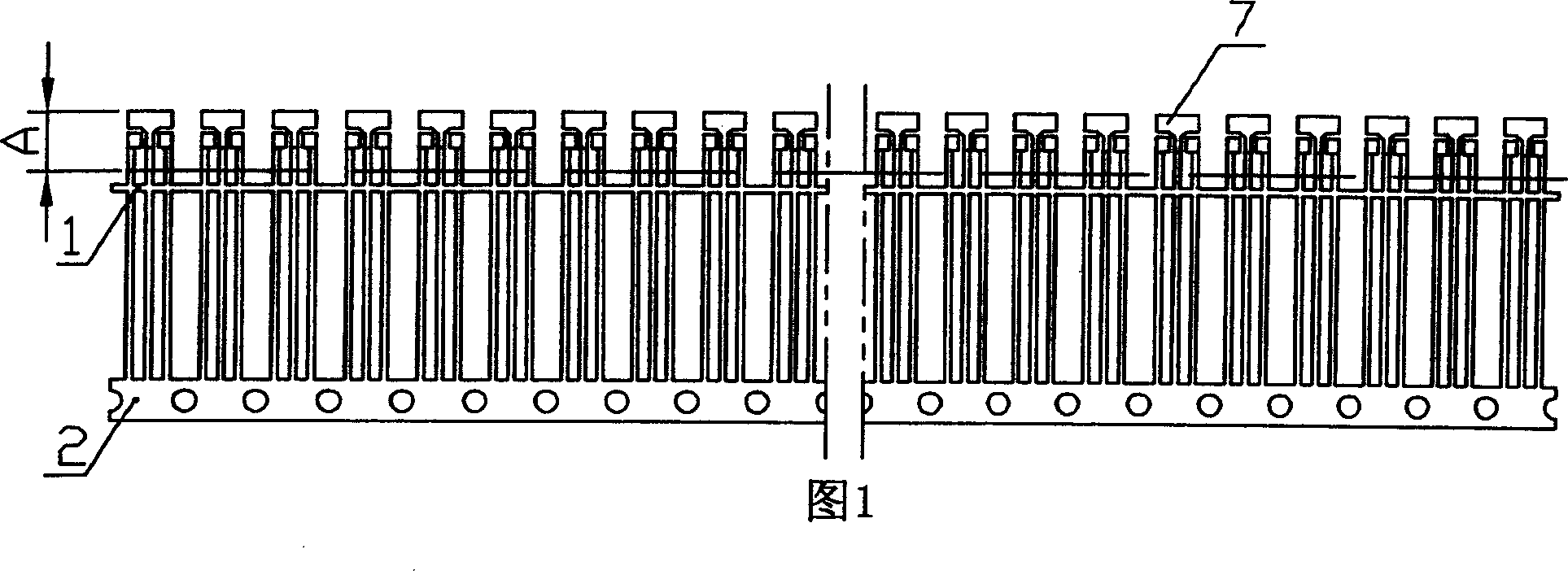

[0017] As shown in Figure 1, the (TO-92) single-row lead frame tape punched out in the prior art has the connecting parts of the side tape 1 and the middle rib 2, and the area that needs to be electroplated is the head area of the lead frame tape. This is area A in the figure. Then separate the lead frame tape: cut the side tape 1 and the middle rib 2 horizontally (that is, along the vertical direction in FIG. 1 ), and then obtain a plurality of lead frame sheets, each lead frame sheet includes a plurality of lead frames.

[0018] The manufacturing method embodiment of lead frame of the present invention:

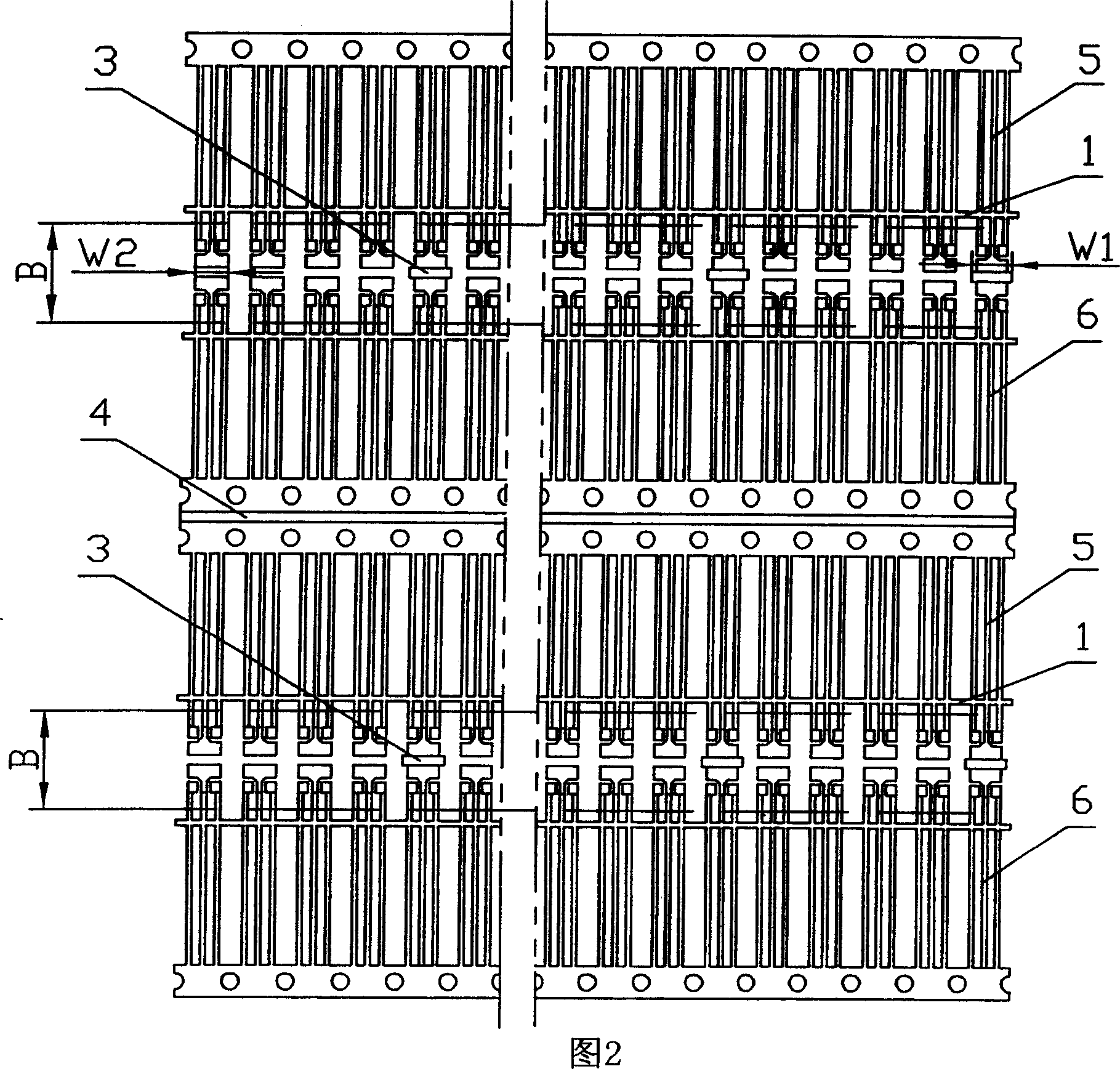

[0019] a. Stamping process: first stamping and manufacturing (TO-92) lead frame tapes, as shown in Figure 2, stamping and manufacturing two lead frame tapes connected by connecting ribs 4 from the same workpiece, and then removing connecting ribs 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com