Reinforced glass guide brackets and supports, and installation method

A technology of glass fiber reinforced plastics and guide frames, which is applied in the direction of pipeline supports, electrical components, pipes/pipe joints/pipe fittings, etc., which can solve problems such as cable arc discharge, inability to support and protect cables, and loss of ships, so as to improve the stability of welding quality, Guaranteed flatness and consistency, saving welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with specific examples, but the protection scope of the present invention should not be limited thereby.

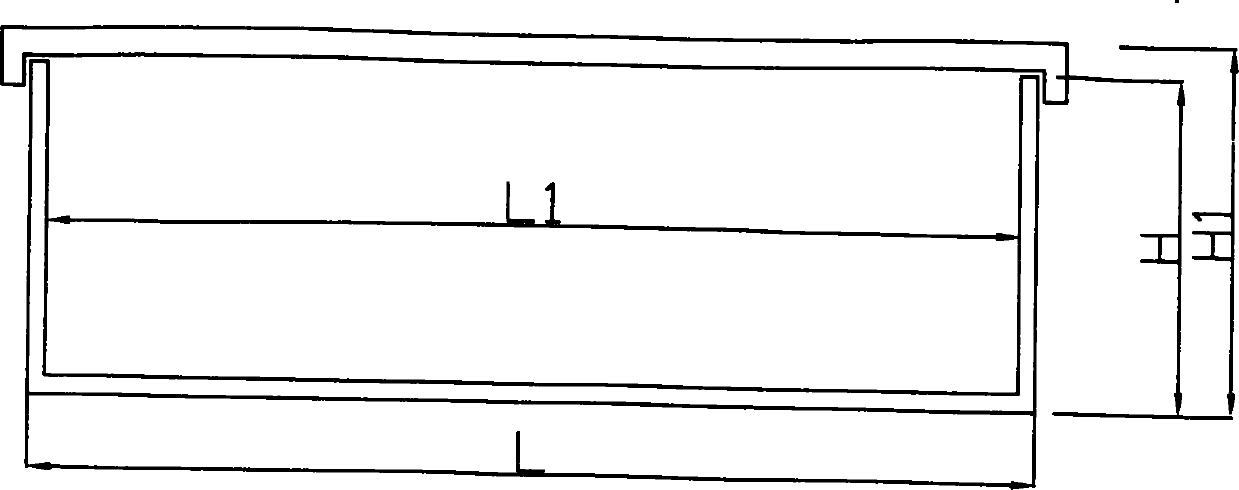

[0048] please see figure 1 , figure 1 It is a schematic cross-sectional view of the FRP guide frame and the bracket and the installation method of the FRP guide frame of the present invention. The fiberglass guide frame shown in the figure is a cross-section of " ” type, or provided with a cross-section of “ "Cover of profile section; FRP guide frame" "Type cross-section with external base width L, internal base width L1, height H, capped" "Type cover height is H1;

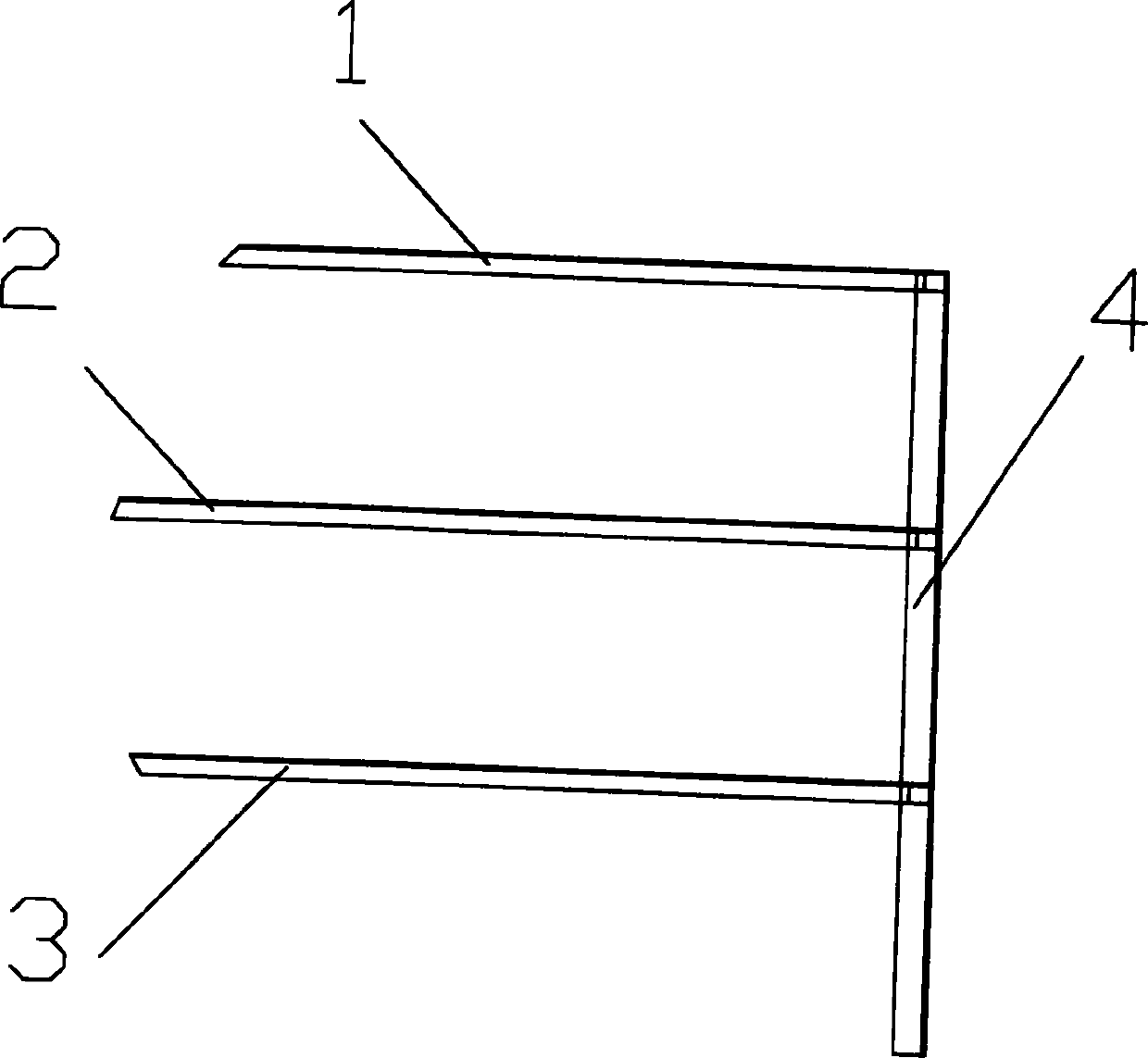

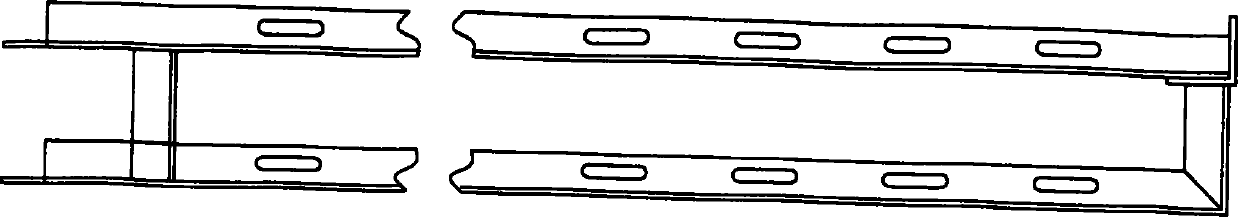

[0049] figure 2 It is the front view of the "E" type combined bracket of the FRP guide frame and bracket and its installation method of the present invention, image 3 It is a top view of the "E" type combined bracket of the FRP guide frame and bracket and its installation method of the present invention. It can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com