Led spotlight having funnel-shaped lens

A LED spotlight, transparent technology, applied in the direction of light source, lighting and heating equipment, electric solid-state devices, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

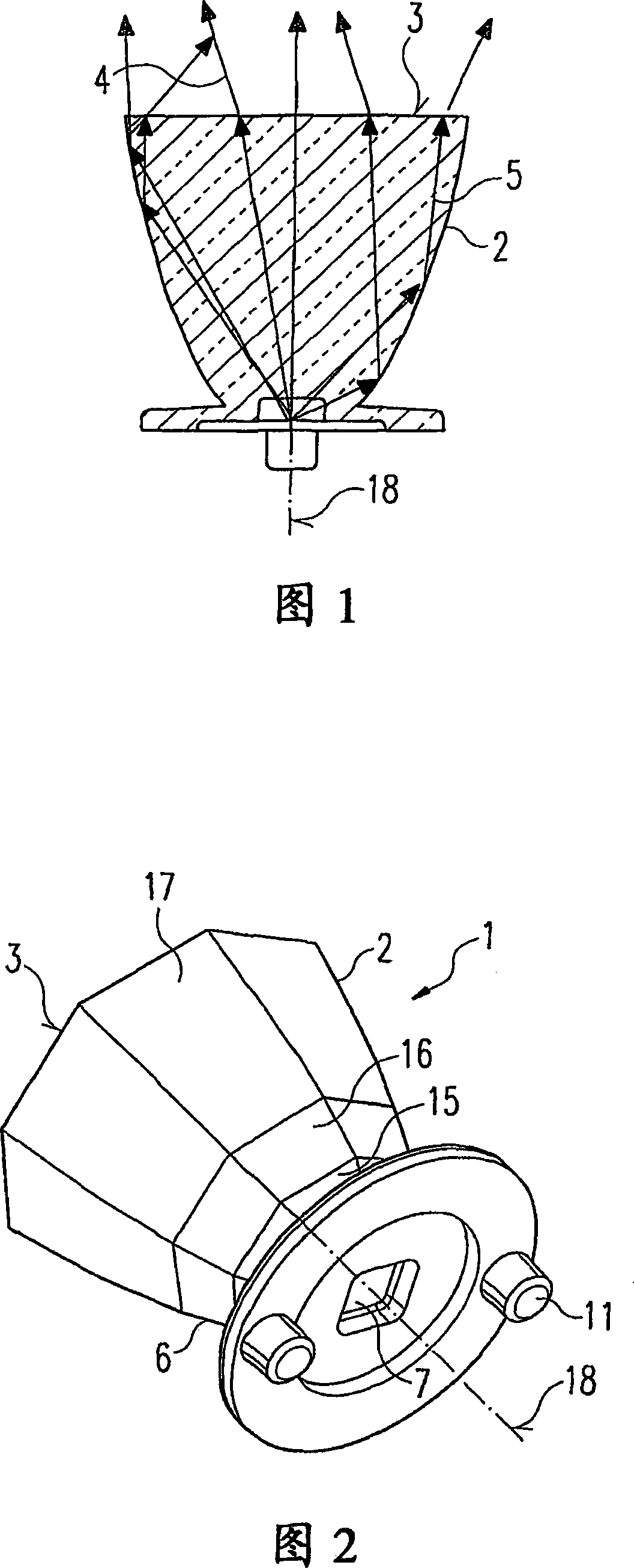

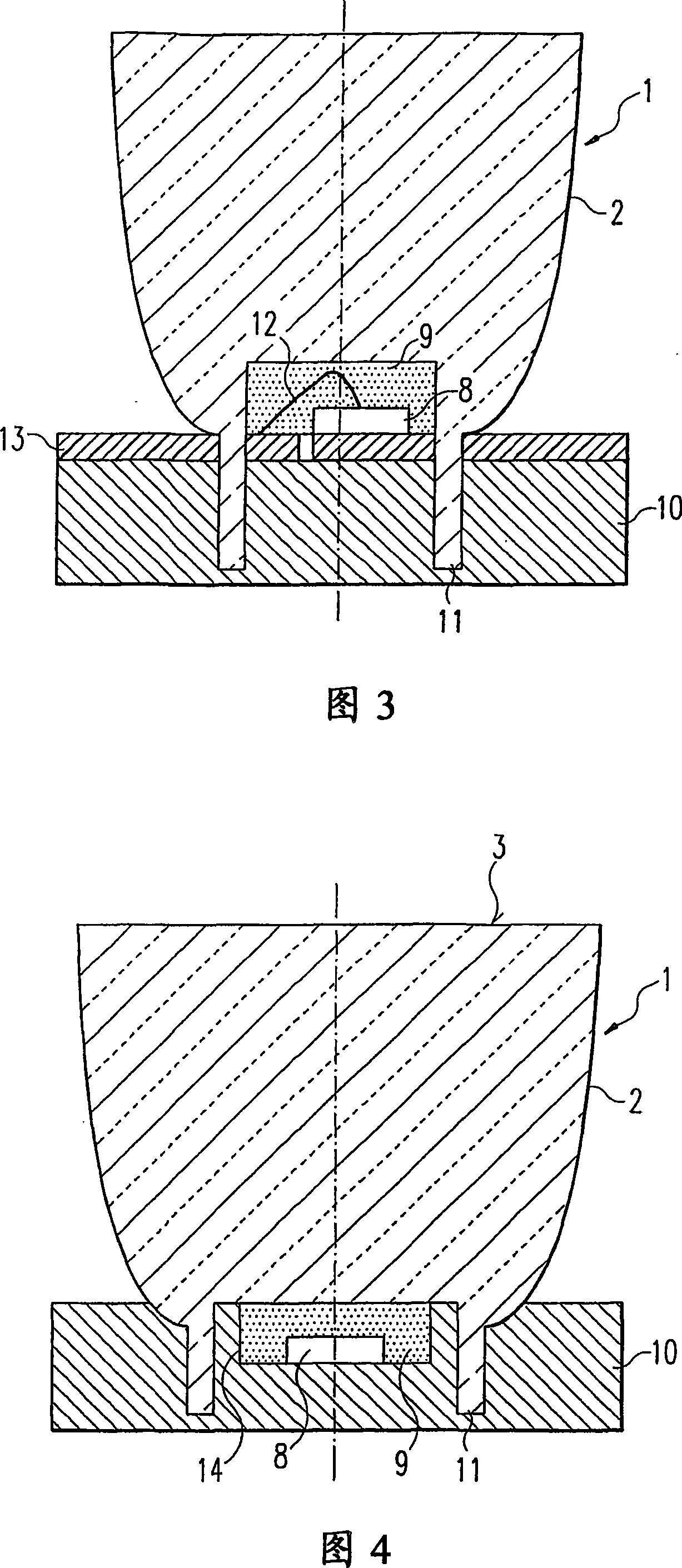

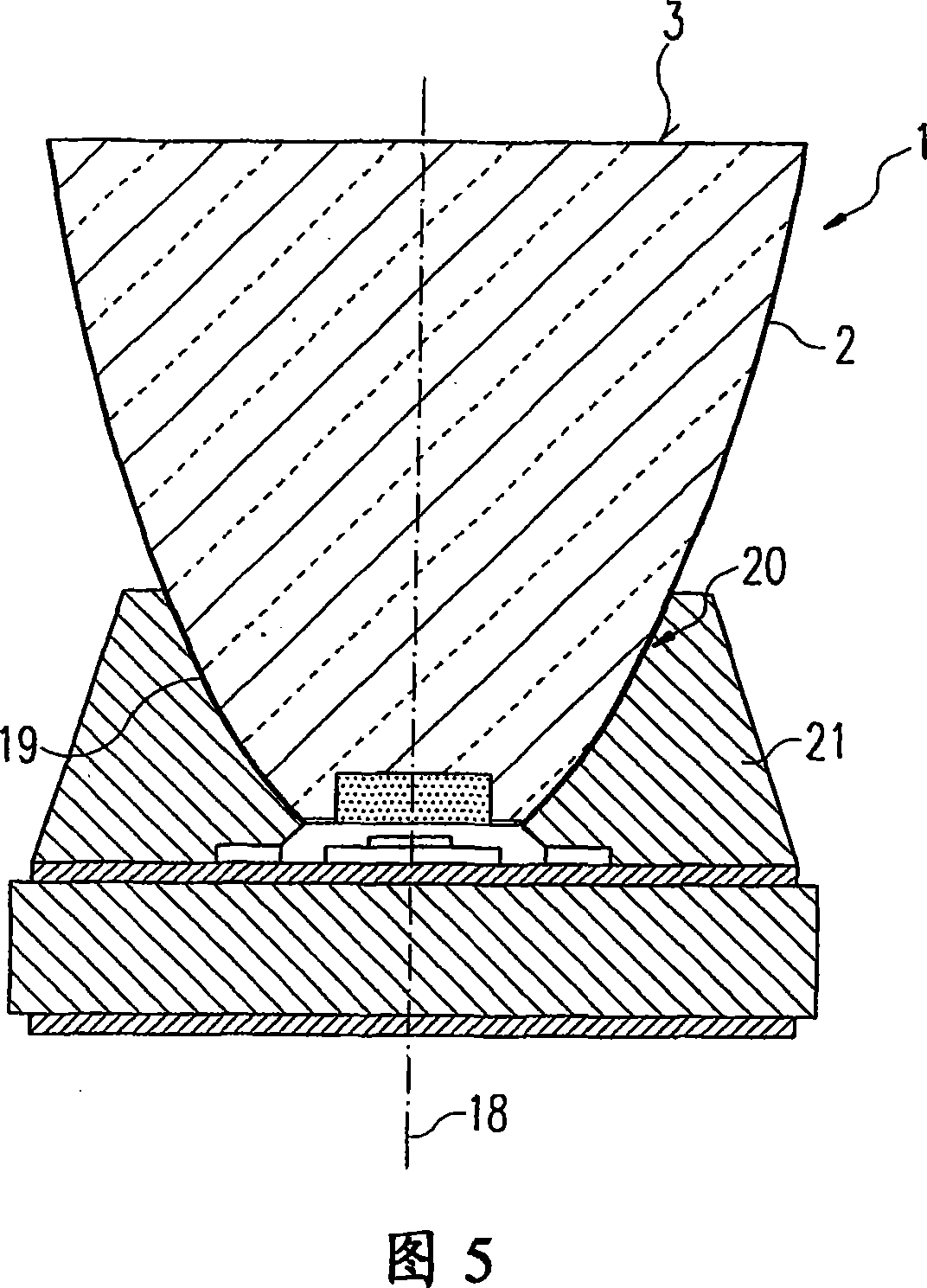

[0040] As shown in Figure 1, according to the present invention there is provided an LED spotlight having a funnel-shaped lens in the form of a conical optical system 1 of substantially transparent solid material having side walls 2 and the exit surface 3 perpendicular to the axis of symmetry of the conical optical system 1. The material of the conical optical system may have a refractive index of, for example, 1.4-1.6, especially 1.5-1.55.

[0041] In the boundary layer from the conical optics to the surrounding air, incident light from the inside is totally reflected so that light does not exit on the side walls of the conical optics. And since the light is actually incident on the exit surface of the conical optical system at a more oblique angle, the light is not reflected but merely refracted away from the normal to the exit surface.

[0042] Through the acute angle of the outer surface of the conical optical system with respect to its axis of symmetry, it is ensured tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com