Water cooling device for printing machine cooling roll

A water-cooling device and cooling roller technology, applied in printing presses, rotary printing presses, rotary flattening presses, etc., can solve the problems of slow water circulation of cooling rollers, large resistance of cooling rollers, affecting feeding tension, etc., and achieve fast circulation speed. , flexible rotation, improve the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

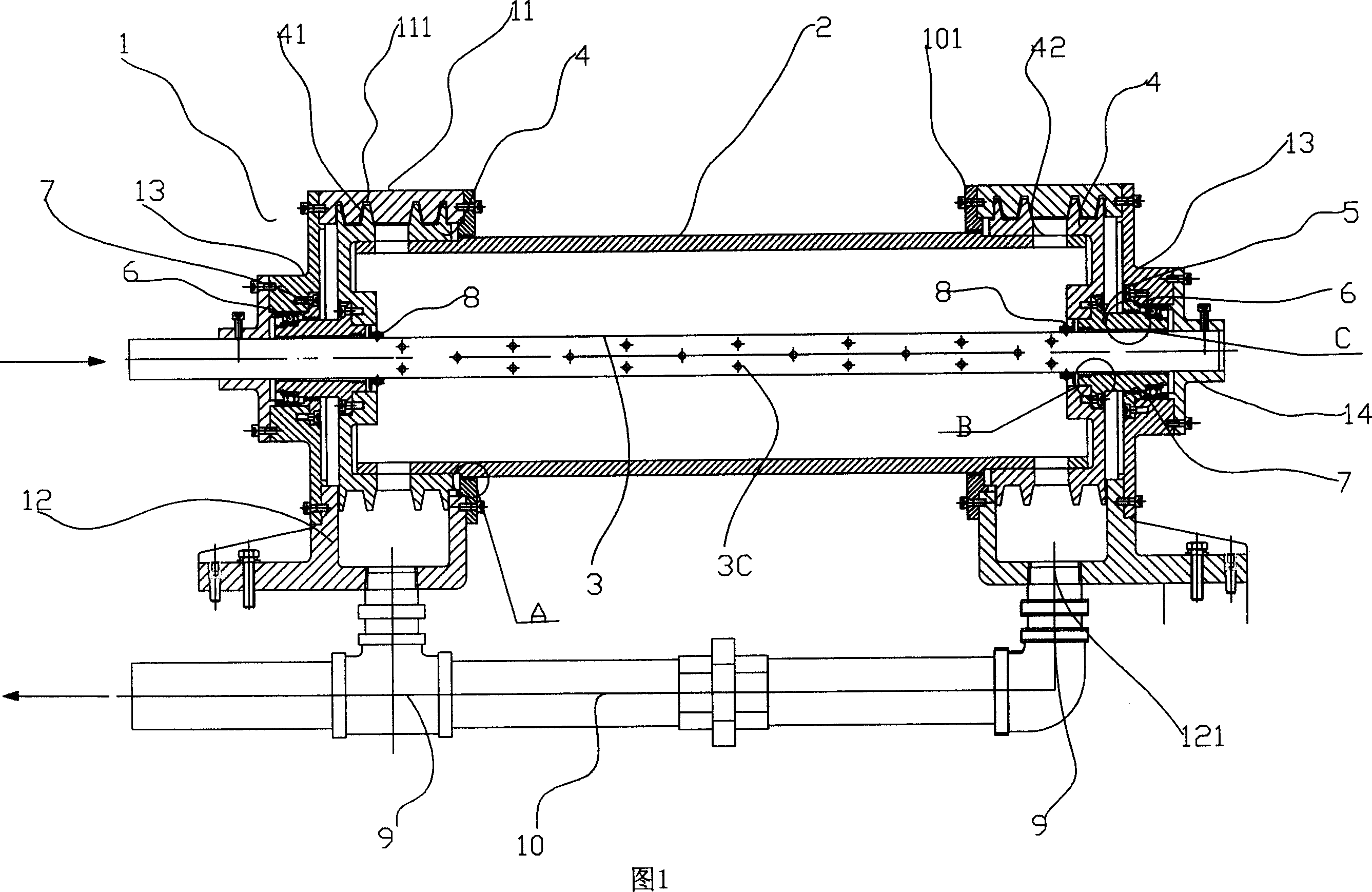

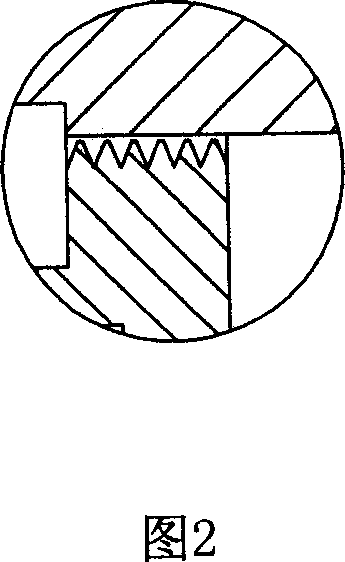

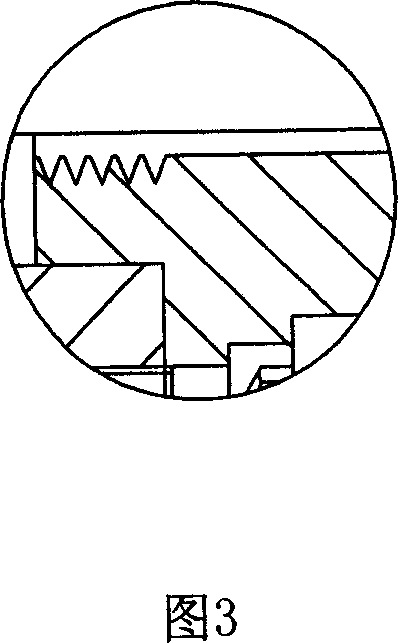

[0019] As shown in Fig. 1-4, the water cooling device of the cooling roller of the printing machine includes a main body frame, a cooling roller 2, a water inlet pipe 3, a water return pipe 10, a water throwing wheel 4, a bearing 6, a bearing seat 5, a sealing ring 8 and other main components. Components, wherein the box body 1 is composed of two sets of upper box body 11 and lower box body 12. After being fixed as a load-bearing body, it is erected on the plane of the printed wall board. The outer end faces of both sides of the box body 1 are connected and fixed with outer end covers 13 by bolts. . There are cooling rollers 2 that can rotate flexibly in the box body 1. The water throwing wheels 4 are set on both ends of the cooling roller 2, one on the left and one on the left. Each water throwing wheel 4 has four convex gear rings 41, two on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com