Lower beam detecting method of vehicular head light detector and detecting mechanism thereof

The technology of a headlamp and a detector is applied in the field of low beam detection of a vehicle headlamp detector and its detection mechanism, which can solve the problems of a large amount of processing data, a complex control system, a long processing time, and the like, and achieves less data processing. , the effect of low hardware requirements and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

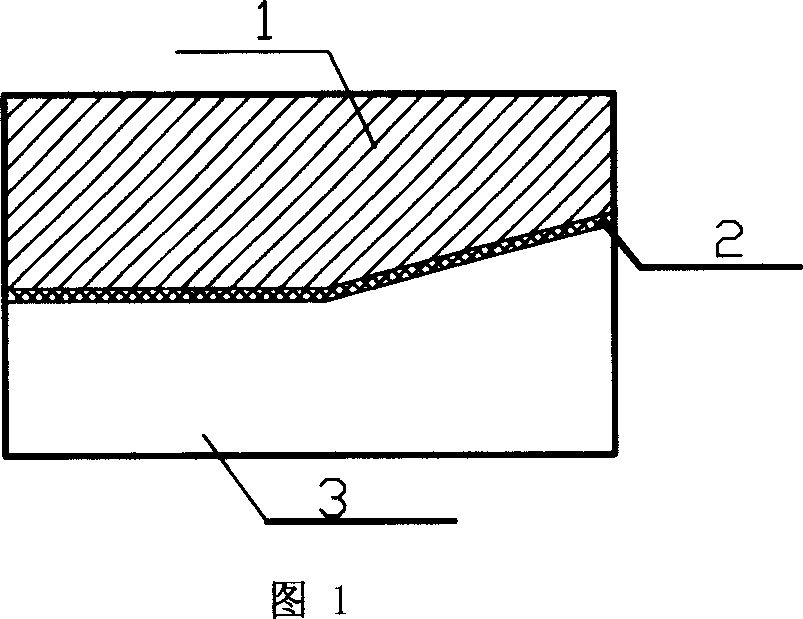

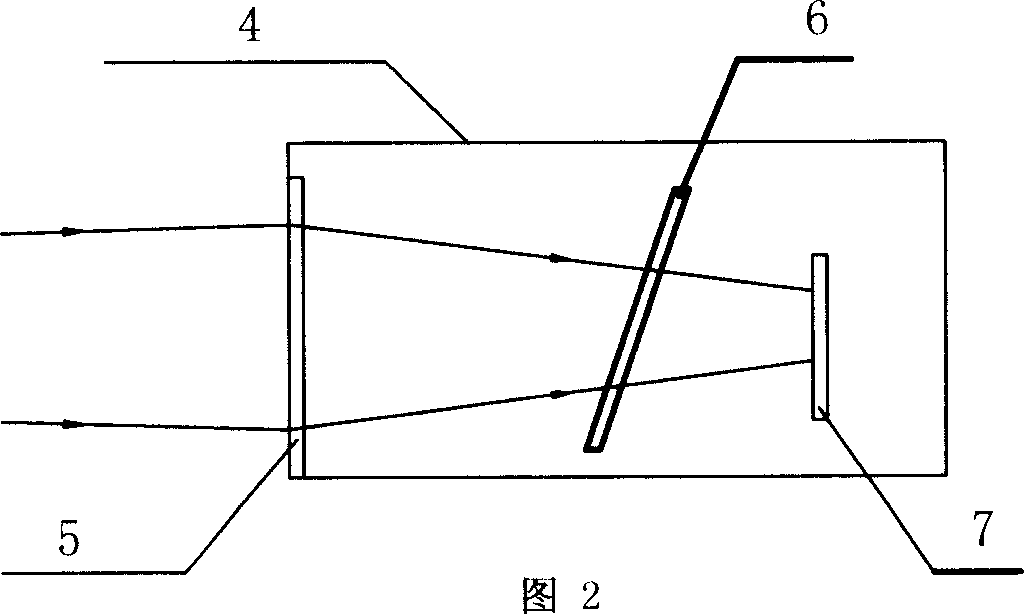

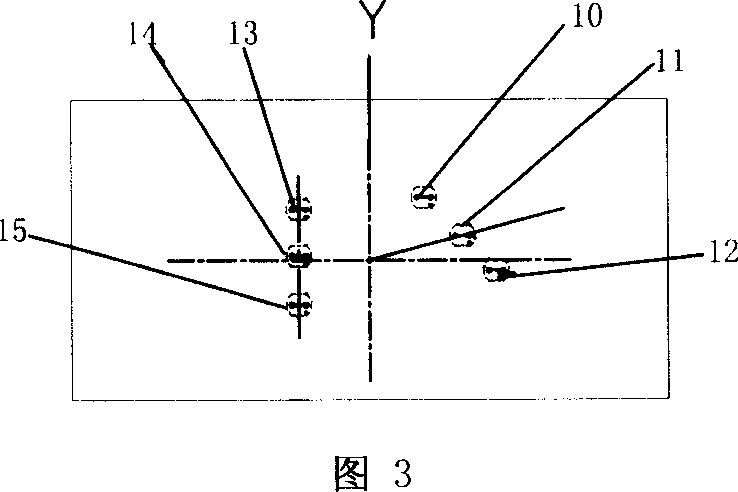

[0016] Referring to FIG. 3 and FIG. 4 , the low-beam light pattern of the measurement screen 7 in this embodiment is divided into a dark area 1 , a light-dark transition area 2 , and a bright area 3 by the low-beam and dark cut-off line 16 . The photoelectric conversion elements on the measurement screen 7 are arranged around the characteristic boundary of the low light and dark cut-off line. On the measurement screen 7, the photoelectric conversion elements are arranged obliquely to the right side of the Y axis and parallel to the Y axis to detect the horizontal irradiation direction of the low beam. The photoelectric conversion element group 9 and the photoelectric conversion element group 8 for detecting the vertical irradiation direction of the low beam arranged on the left side of the Y axis and parallel to the Y axis, and the photoelectric conversion element group 9 for detecting the horizontal irradiation direction of the low beam are converted by the upper horizontal lig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap