Wafer fuse and its making method

A fuse and chip technology, which is applied in the manufacture of fuses, semiconductor/solid-state devices, emergency protection devices, etc., can solve the problems of increasing production costs, easy to pollute the environment, and cumbersome manufacturing processes, and achieve the effect of increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Regarding the screw of the present invention, the technical means adopted and the effect of achieving the above-mentioned purpose are easy to understand. Hereby, a detailed description is made with the best embodiment in conjunction with the simple description of the drawings and the symbols of each component as follows:

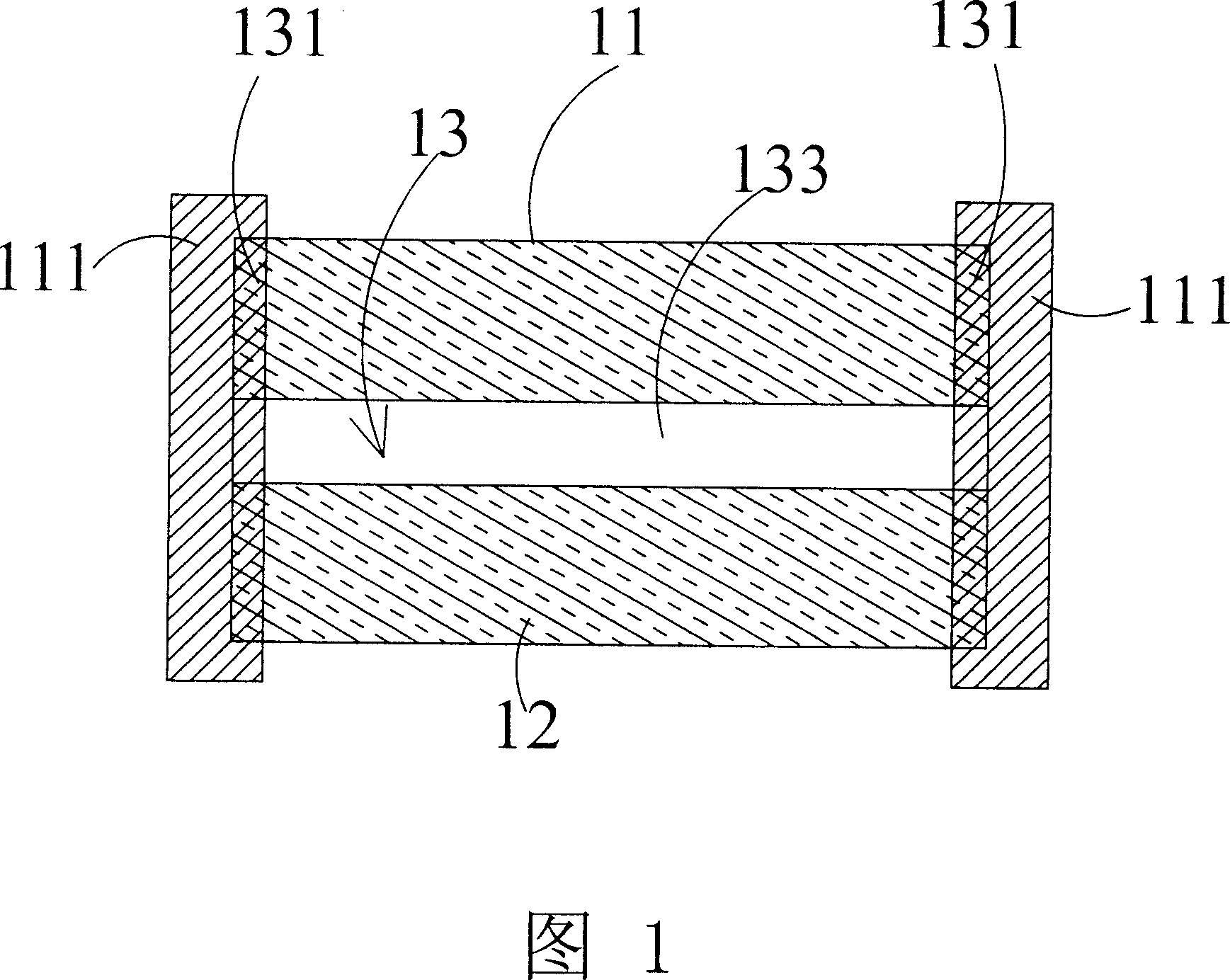

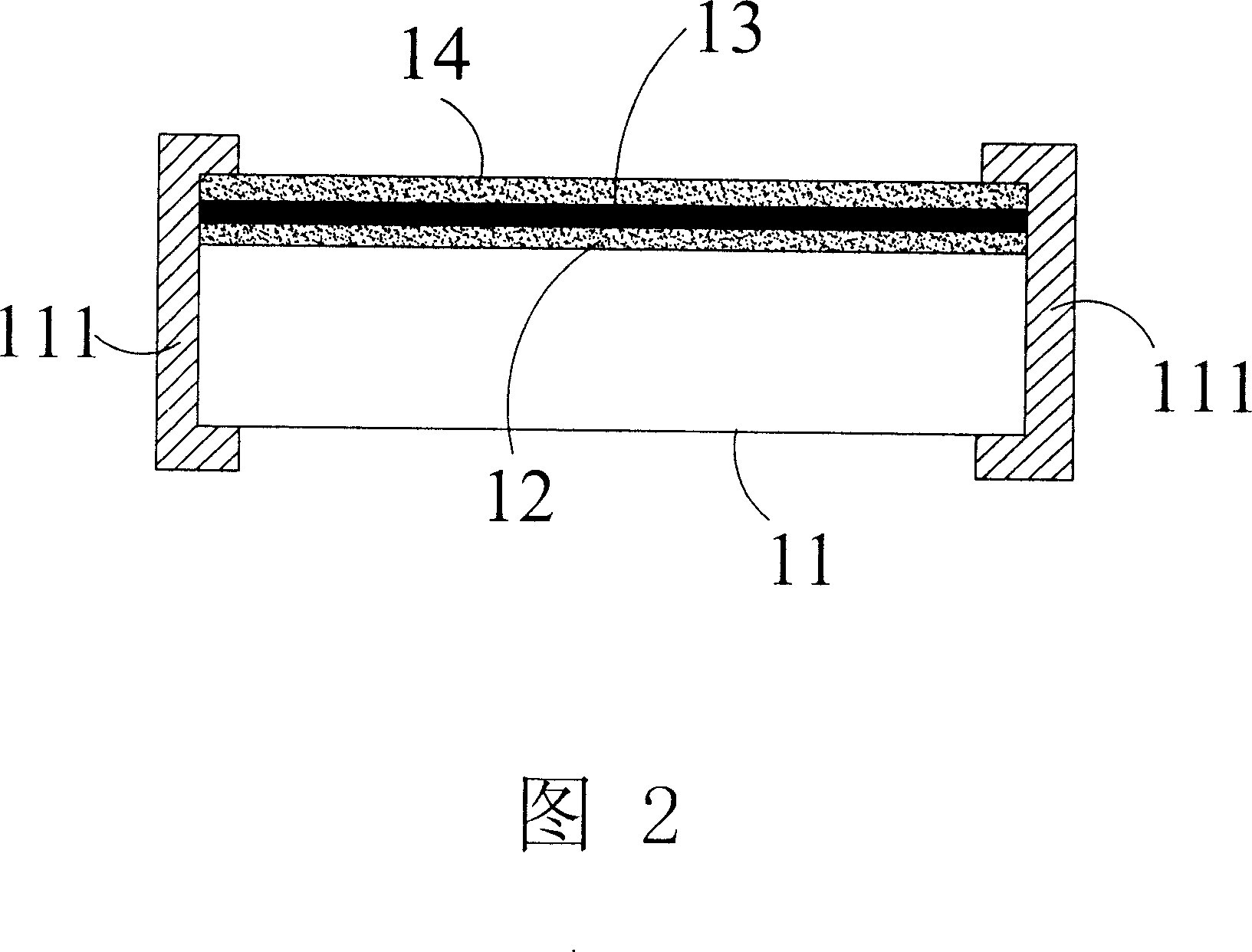

[0016] The present invention relates to a chip fuse and its manufacturing method, please refer to Figures 1 and 2, wherein the chip fuse includes:

[0017] Wafer substrate 11, forming terminal electrodes 111 on its two end faces;

[0018] The first matrix 12 is made by coating a layer of heat insulating material between the two terminal electrodes 111;

[0019] The second substrate 13 is made by printing an organic metal material on the surface of the first substrate 12 by a thick film printing method, and has two end parts 131 and a middle part 133, so that the two end parts 131 and the two ends The electrodes 111 are electrically connected;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com