Filling mold and its building operation method

A technology for building construction and filling molds, which is applied in the direction of buildings, building components, and building structures. performance, shorten the construction period, and improve the feasibility of secondary design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

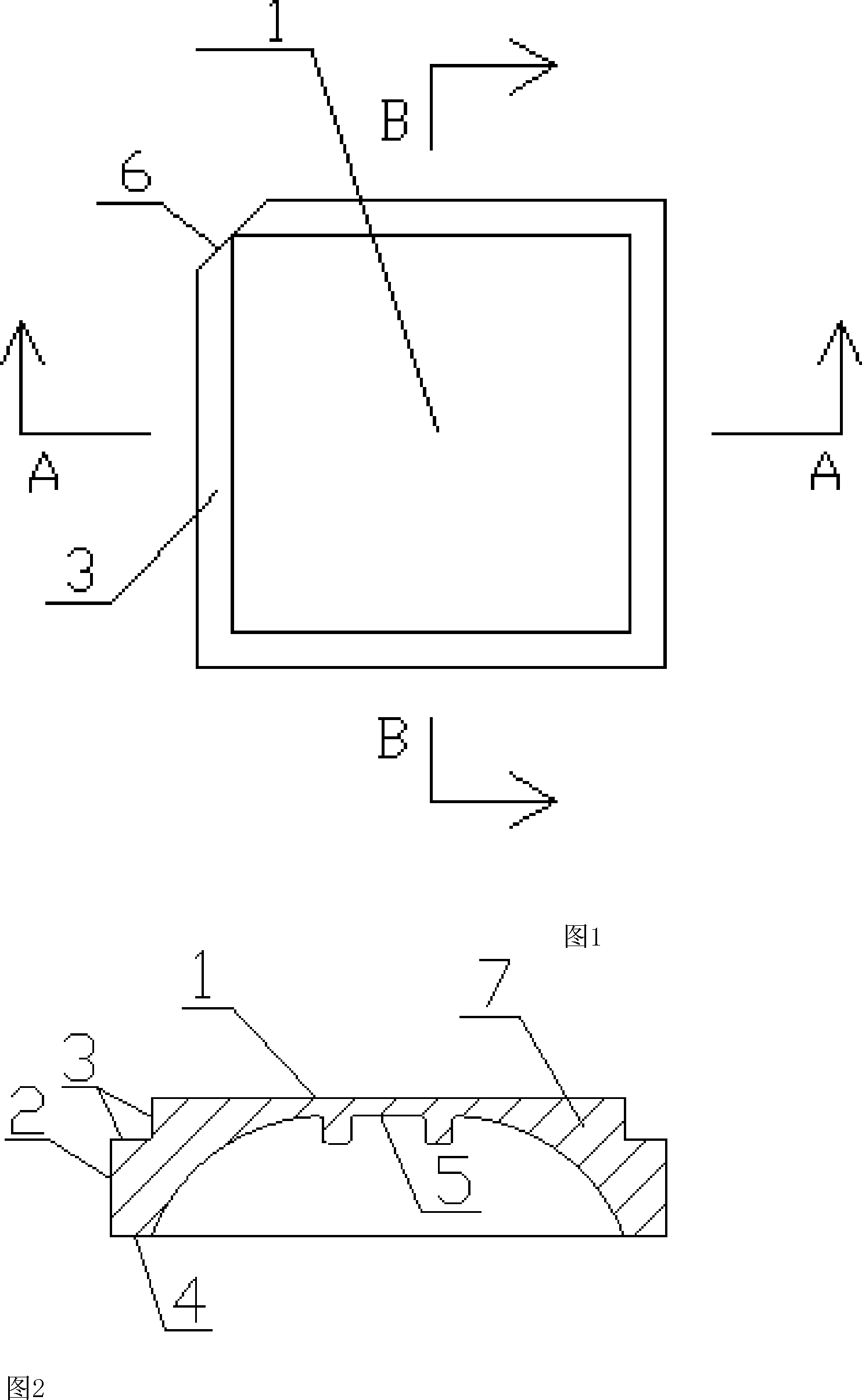

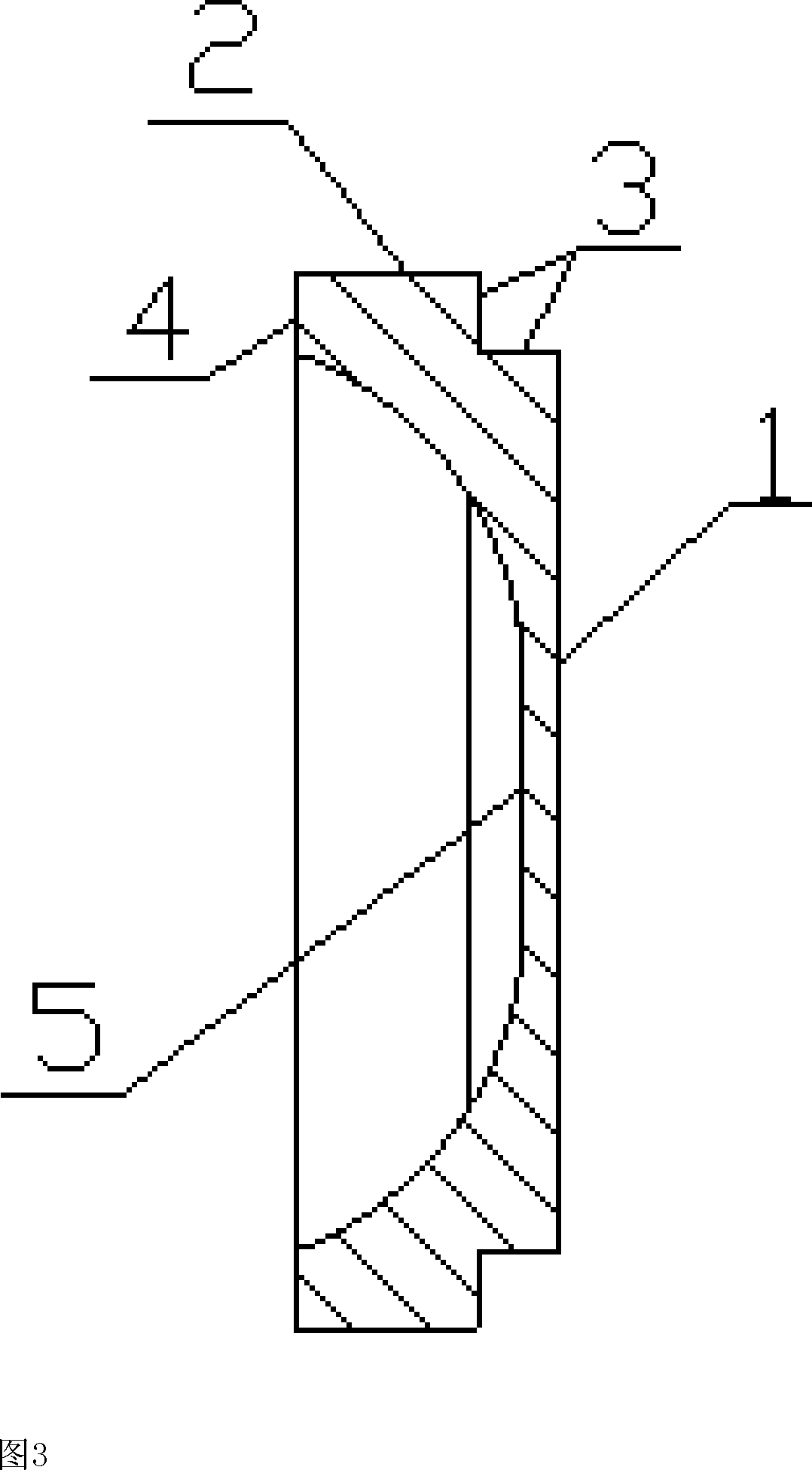

[0034] Embodiment 1: the structure of filling mold is shown in Fig. 1, Fig. 2 and Fig. 3, and the top surface of mold box 7 is die face 1, and die face 1 is the rectangular plane of long 50cm, wide 50cm, the edge of die face 1 and The upper edge of the mold side 2 has a concave platform 3, the plane of the concave platform 3 is a rectangle with a length of 60 cm and a width of 60 cm, and the height of the mold box 7 is 15 cm; The included angles of the planes of the platform 3 are right angles, and the inner cavity of the bottom surface of the mold box 7 is the mold inner surface 5, which is a concave curved surface as shown in Fig. 1 . There is a chamfer 6 on the concave table 3 (all 4 corners can be processed into a chamfer, and in this example, one corner is selected as a chamfer), and the material used for filling the mold is industrial waste phosphogypsum or desulfurization in this example plaster.

Embodiment 2

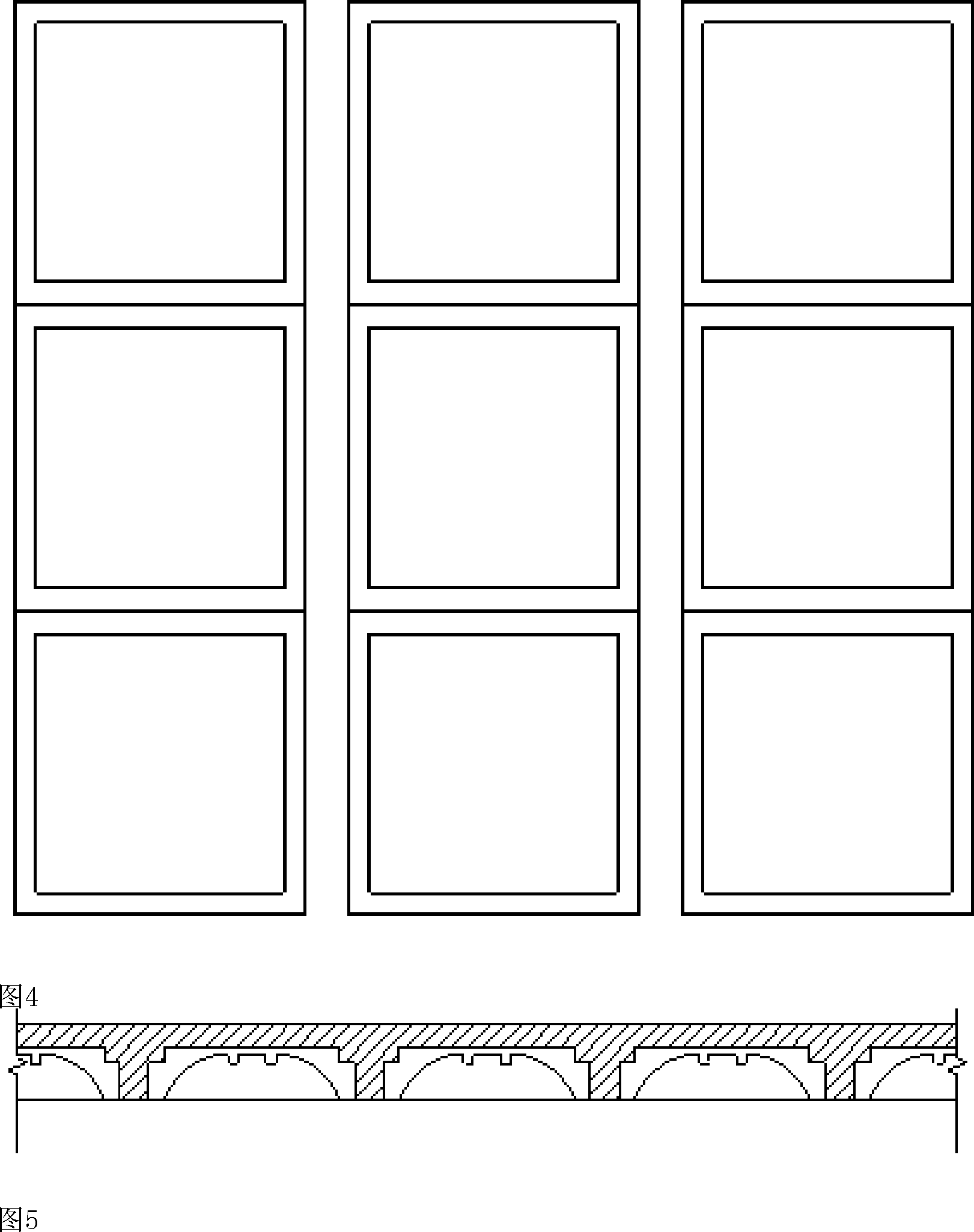

[0035] Embodiment 2: the building structure obtained by the method of filling the mold in the building floor construction as shown in Figure 4, Figure 5 and Figure 6, the bottom surface of the mold 4 is downward, the mold boxes 7 are arranged in a single layer, and the two mold boxes 7 in the horizontal direction are arranged in a single layer. The space between them is arranged with gaps, the gap distance is 7cm, and the two longitudinal mold boxes 7 are closely arranged (there is no gap in the middle); the hollow floor slab formed by injecting reinforced concrete forms a main T-shaped section in the horizontal direction and a secondary T-shaped section in the vertical direction. .

Embodiment 3

[0036] Embodiment 3: The building structure obtained by the method of filling the mold in the construction of the building floor slab is shown in Figure 7 and Figure 8. The mold boxes 7 are arranged in a single layer, and the bottom surface of the mold 4 is upward, and sealed with a thin plate. Between the two mold boxes 7 in the horizontal direction There is a gap arrangement between them, the gap distance is 6cm, and there is a gap arrangement between the two vertical mold boxes 7, the gap distance is 8cm; the hollow floor slab formed by injecting reinforced concrete forms a two-way mouth-shaped section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com