Manufacturing method of plasma display panel

A technology of a display panel and a manufacturing method, which is applied in the manufacture of discharge tubes/lamps, cold cathodes, tubes/lamp screens, etc., can solve the problems such as the reduction of the light transmittance and internal pressure characteristics of the display panel, and improve the transmittance. and internal pressure characteristics, the effect of preventing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

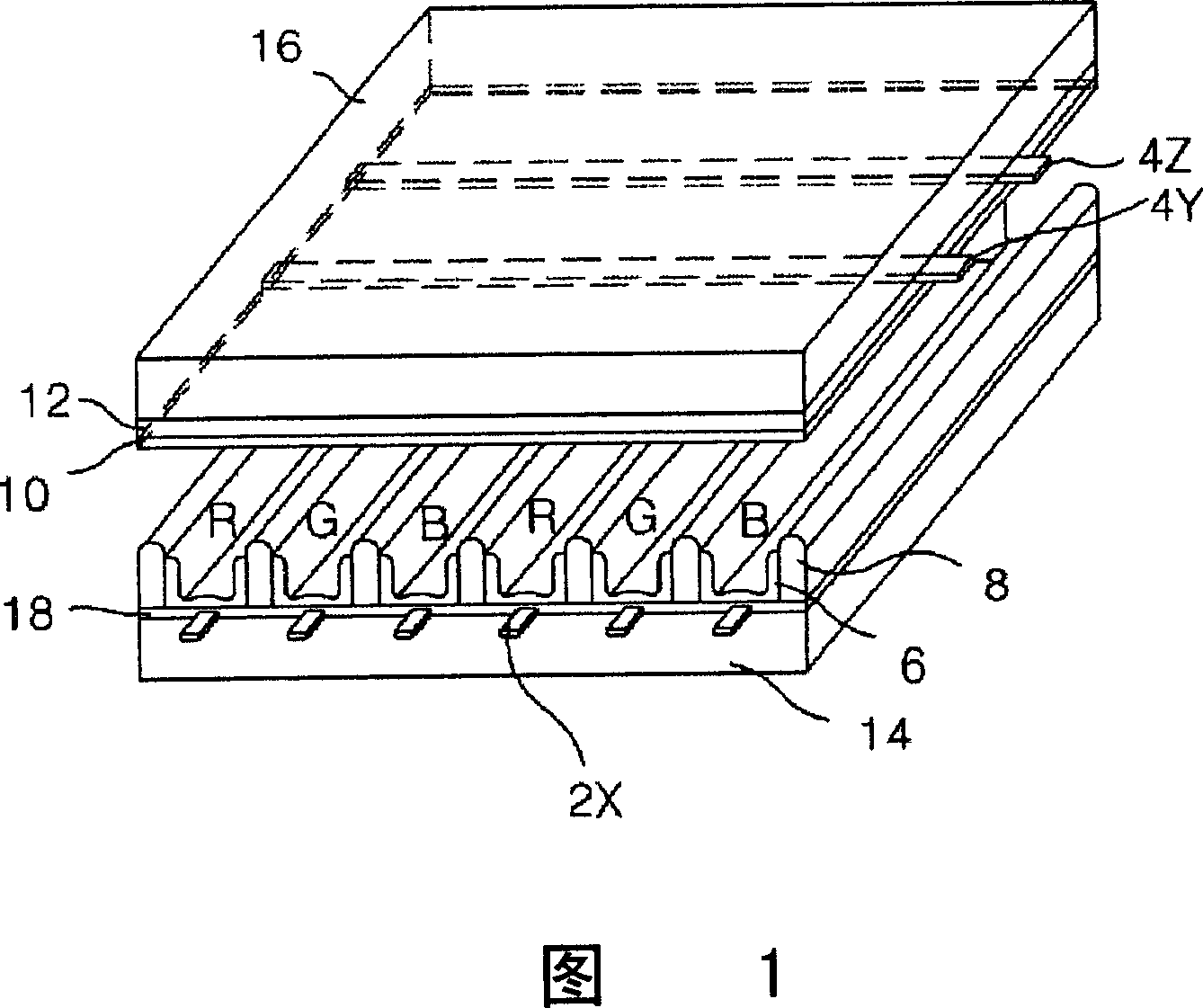

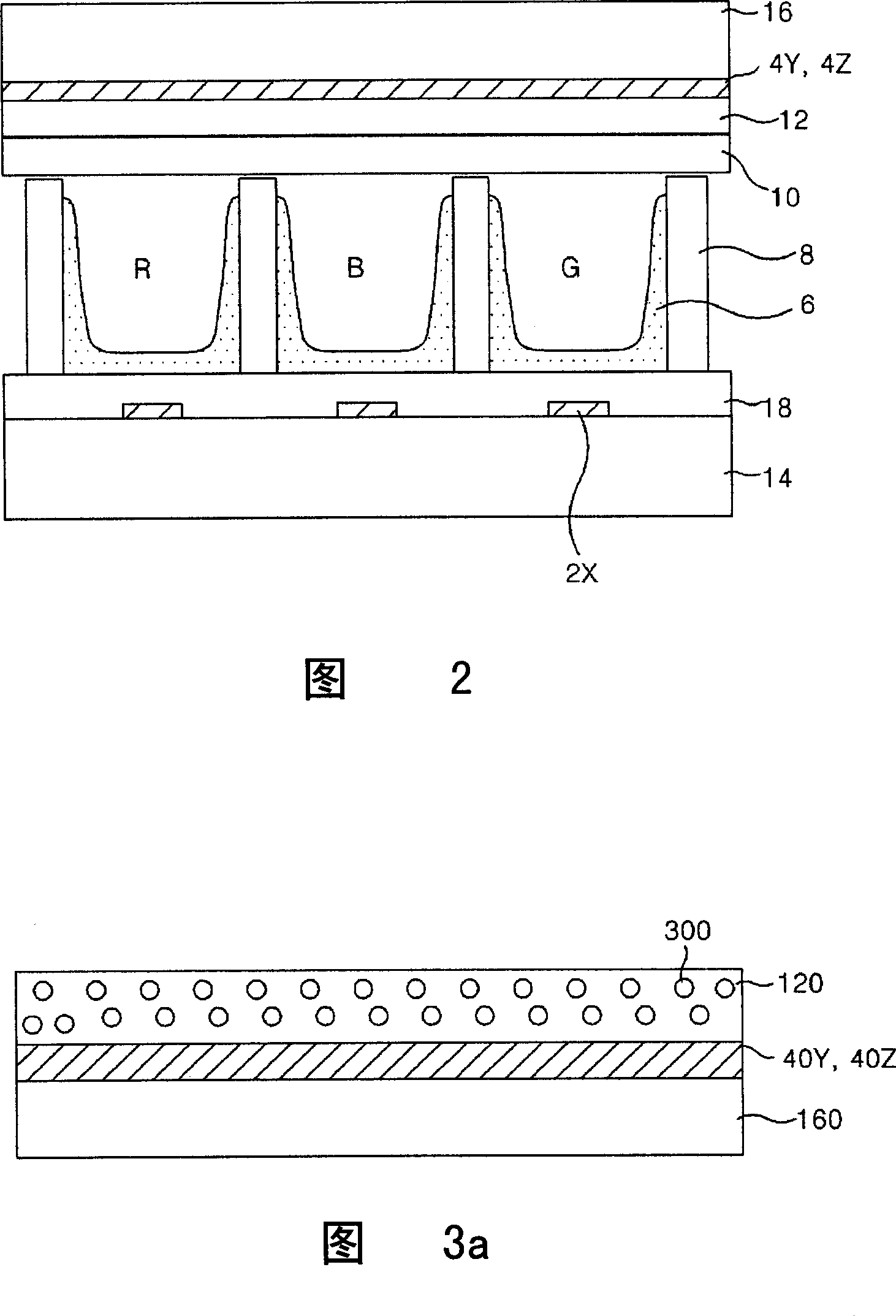

[0031] Hereinafter, an embodiment of a method of manufacturing a plasma display panel of the present invention will be described in detail with reference to the drawings.

[0032] In the following description, only the case of the charged layer formed on the upper substrate and the lower substrate will be described, but the case of the pressed charged substance on other plasma display panels is also the same as described here.

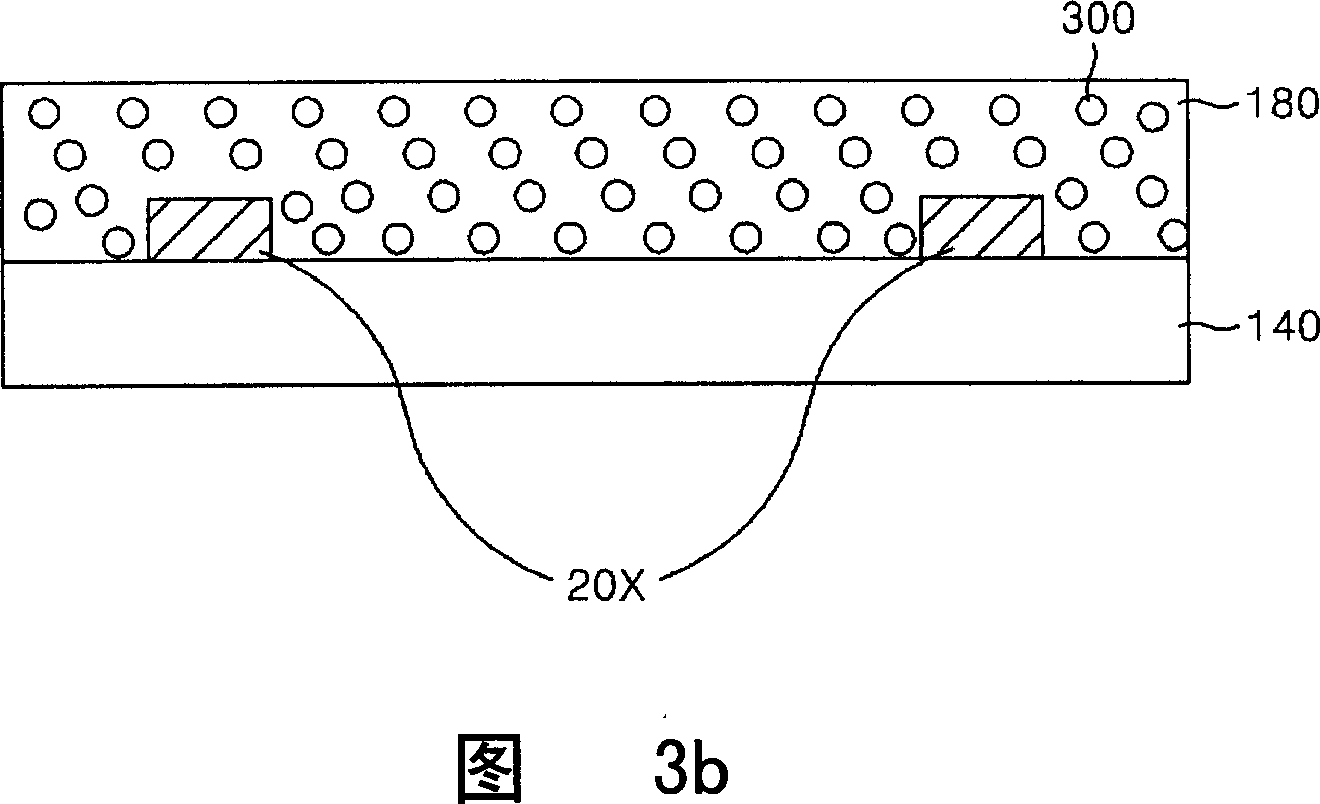

[0033] Shown in FIGS. 3a and 3b are other plasma display panels according to embodiments of the present invention.

[0034] FIG. 3 a illustrates the lower charged layer 180 pressed on the lower substrate 140 of the plasma display panel; FIG. 3 b illustrates the upper charged layer 120 pressed on the upper substrate 160 .

[0035] First, the upper substrate 160 is described: the scan / sustain electrode 40Y and the common sustain electrode 40Z are formed side by side on the upper substrate 160; a mixture of charged substances and oxygen particles (O 2 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com