Encapsulation structure of optical sensor with gap wall

A technology of optical sensor and packaging structure, which is applied in the field of optical sensor packaging structure with spacers, and can solve the problems of abnormal light sensing function, difficult colloid control, and contamination of metal balls 14, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

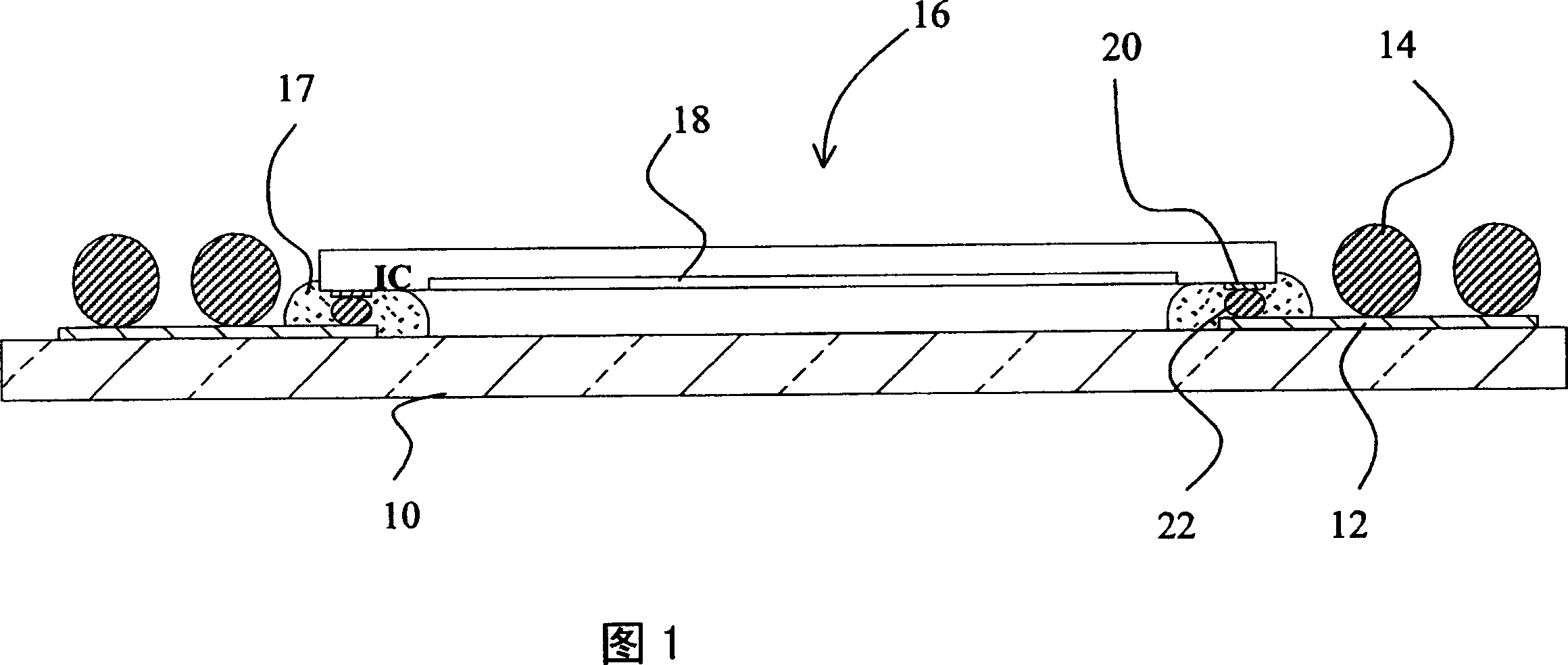

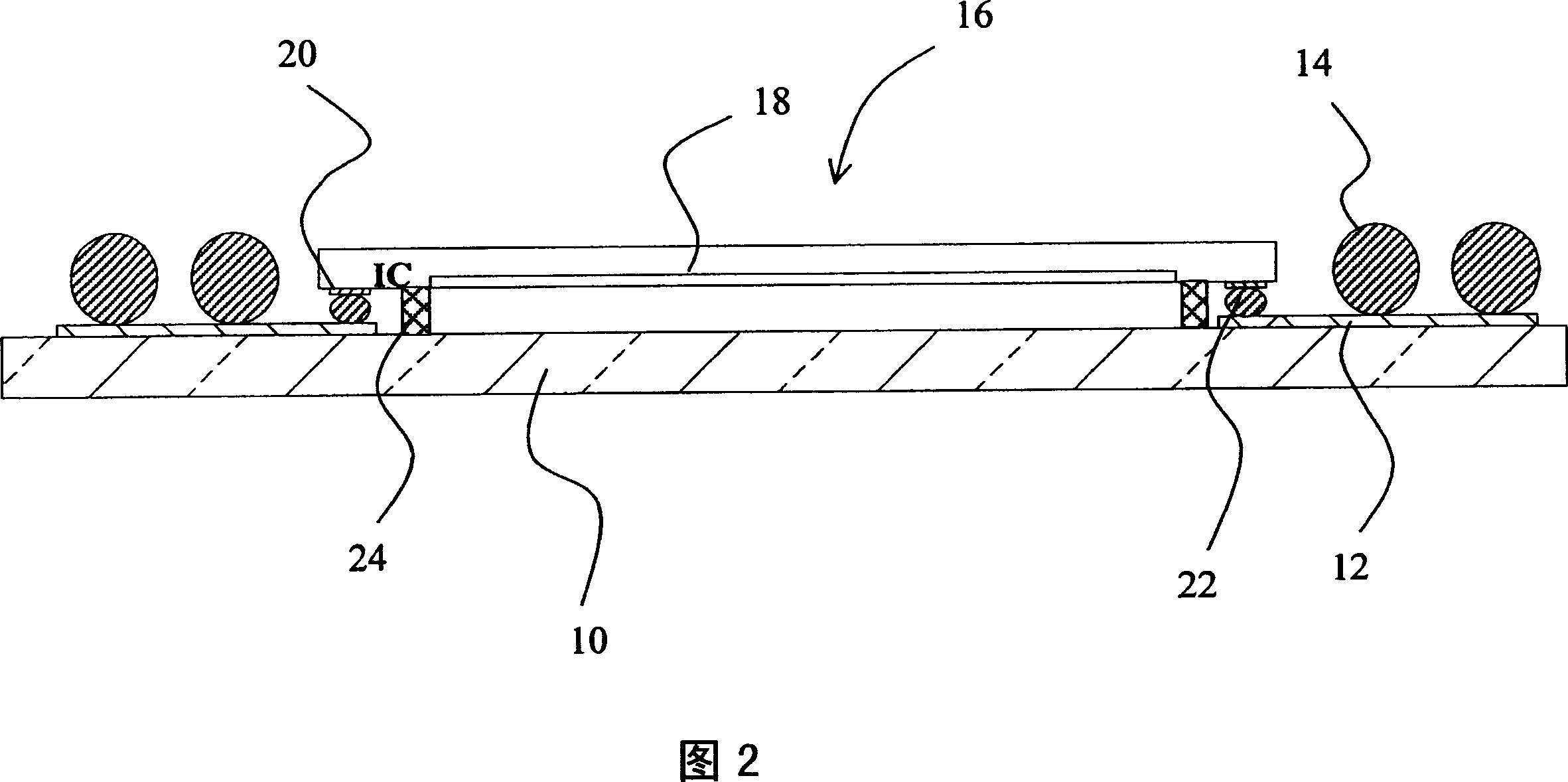

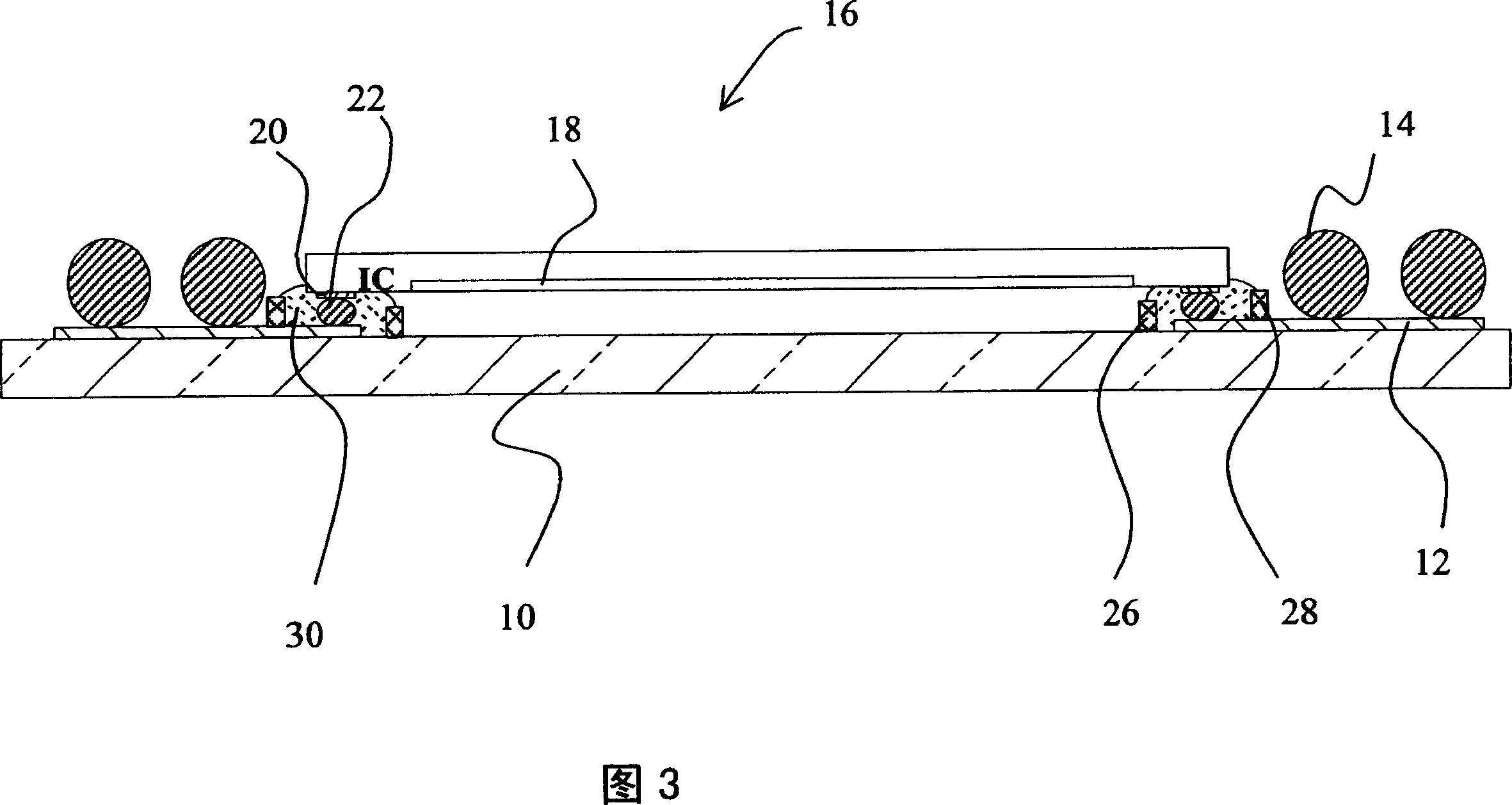

[0032] The invention relates to a photosensor packaging structure that uses a spacer to prevent foreign pollutants from contaminating the light sensing area, and a photosensor package that uses a spacer to prevent colloid from polluting the position where an electrical contact is to be formed.

[0033] Please refer to FIG. 2, which is a schematic diagram of an embodiment of the present invention. The present invention mainly includes a light-transmitting substrate 10, which can be a light-transmitting glass that can filter a certain wavelength. Metal wiring 12 is arranged on the light-transmitting substrate 10. and a plurality of metal balls 14 located on the metal wiring 12; a light-sensing component 16, which includes a light-sensing area 18 and a plurality of welding pads 20, and there are a plurality of welding pads 20 on the welding pad 20 for forming electrical connections with the metal wiring 12. and a spacer 24 between the welding pad 20 and the photosensitive region 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com