Coal-seam high-pressure pulsating water hammer water-infusion method and apparatus thereof

A technology of water hammer and high pressure, which is applied in safety devices, earthwork drilling, mining equipment, etc. It can solve the problems that it is difficult to achieve the ideal effect, the static water pressure is limited, and the air permeability is not applicable, so as to prevent coal mine safety problems and improve Effects of productivity, safety, and wide availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

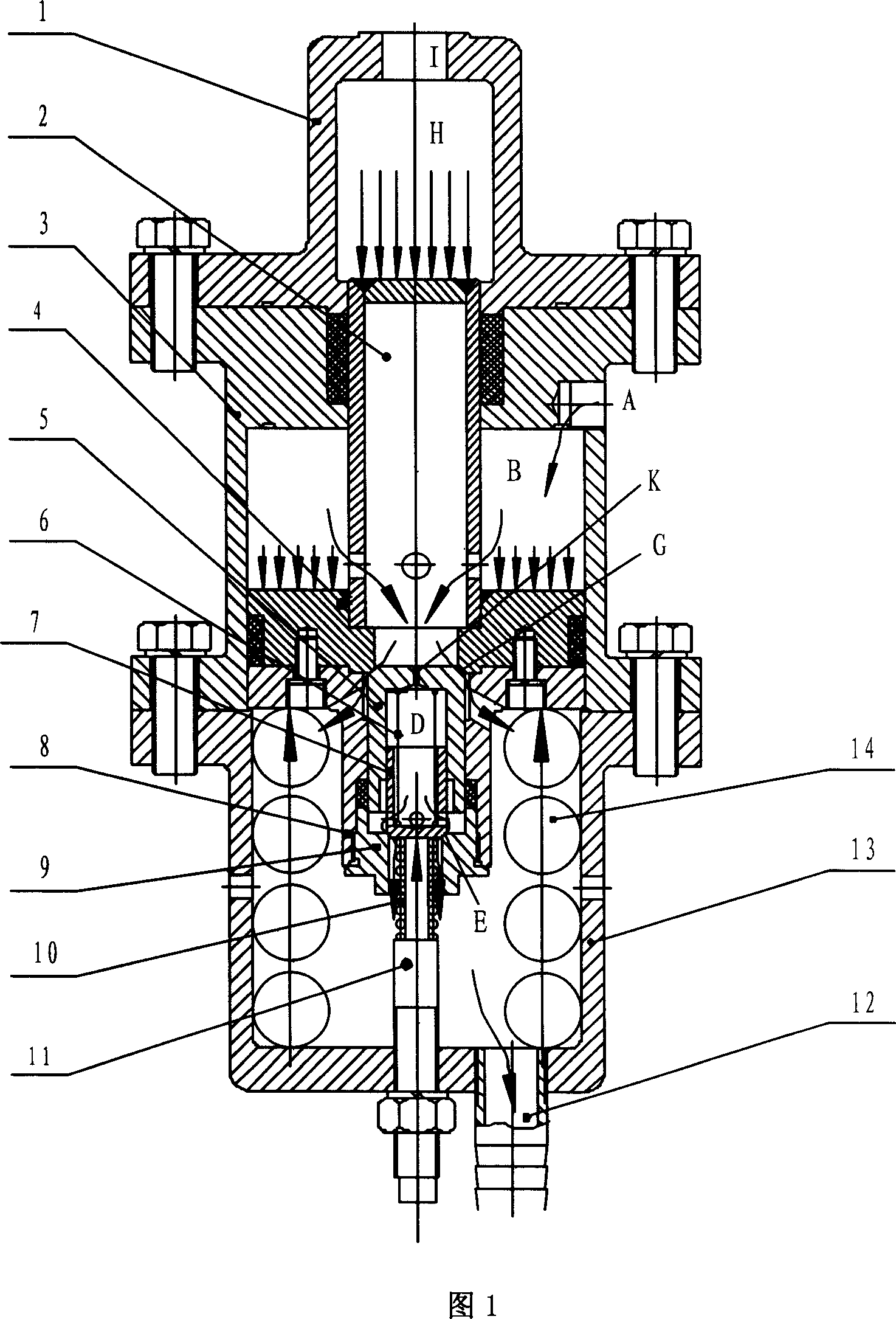

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0013] As shown in the figure, the coal seam high-pressure pulsating water hammer water injection device consists of a high-pressure cylinder 1, a hollow pipe plunger 2, a low-pressure cylinder 3, a piston 4, a main valve core 5, a return spring 6, a trigger valve core 7, and a valve core jacket 8 , Seat nut 9, trigger spring 10, trigger push rod 11, water outlet joint 12, main spring 13 and main spring seat 14. The high pressure cylinder 1 is fixed on the top of the low pressure cylinder 3, and the main spring seat 13 is fixed on the bottom of the low pressure cylinder 3, and the high pressure cylinder 1, the low pressure cylinder 3 and the main spring seat 13 are connected as a whole with screws. The cavity of the low-pressure cylinder 3 and the main spring seat 13 is provided with a piston assembly that can move up and down as a whole. The piston assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com