Pressure oil box for removing gas in hydraulic oil liquid

A pressurized oil tank and hydraulic oil technology, which is applied in the direction of oil supply tank devices, mechanical equipment, etc., can solve the problems of inability to separate air bubbles, low inlet pressure, hydraulic pump suction, etc., and achieve the effect of speeding up the removal speed and preventing suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

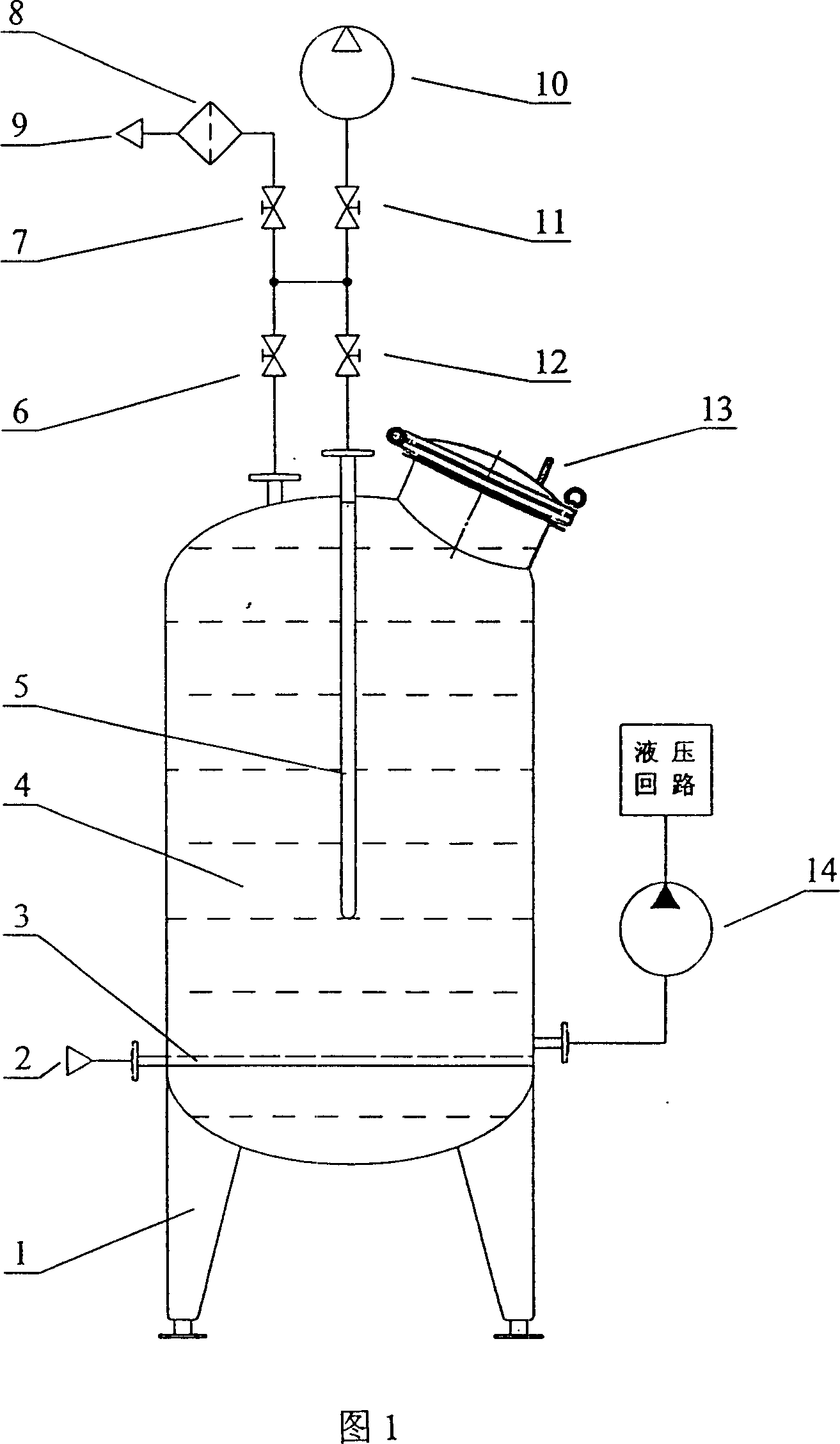

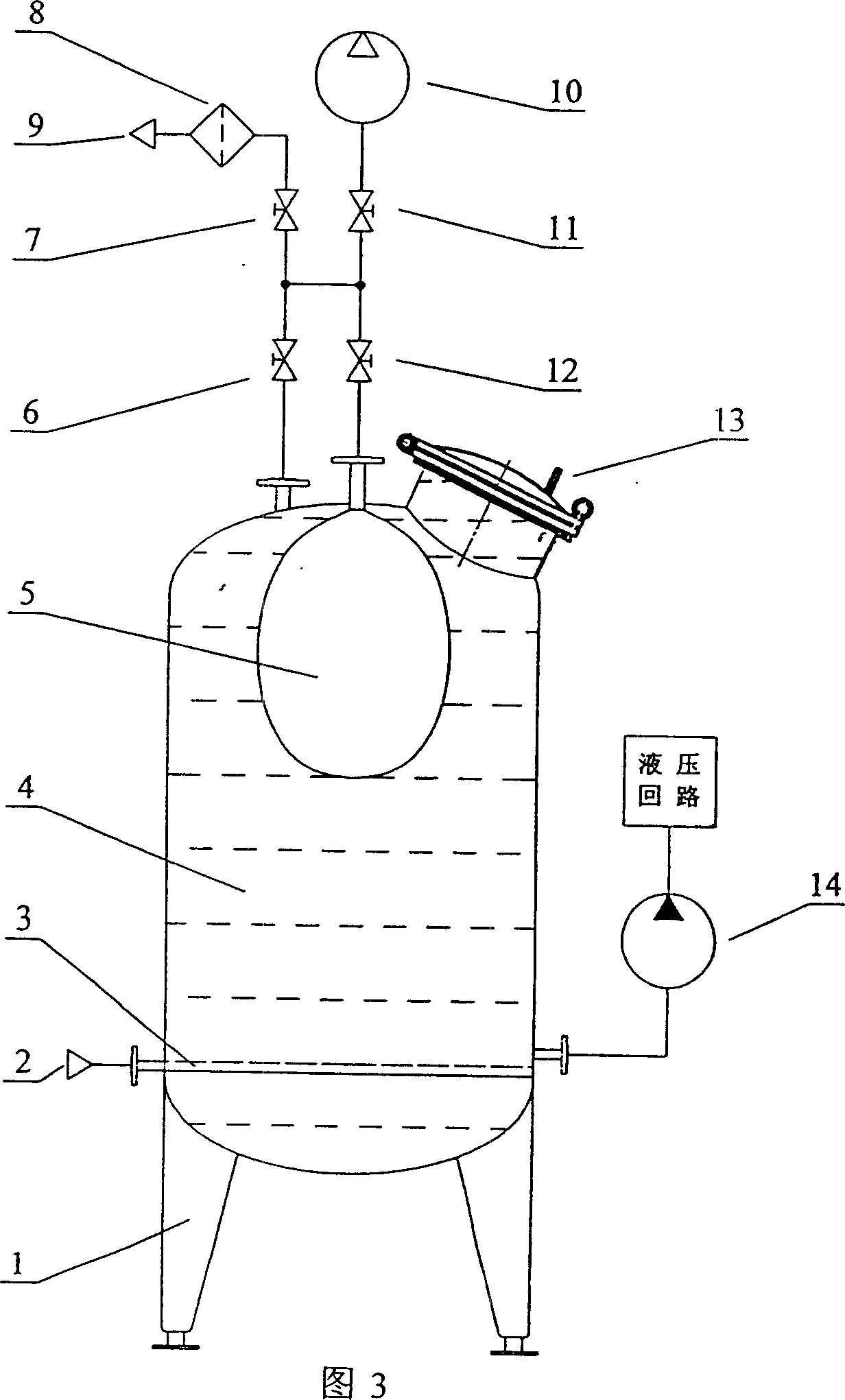

[0020] The present invention will be further illustrated by the accompanying drawings and examples.

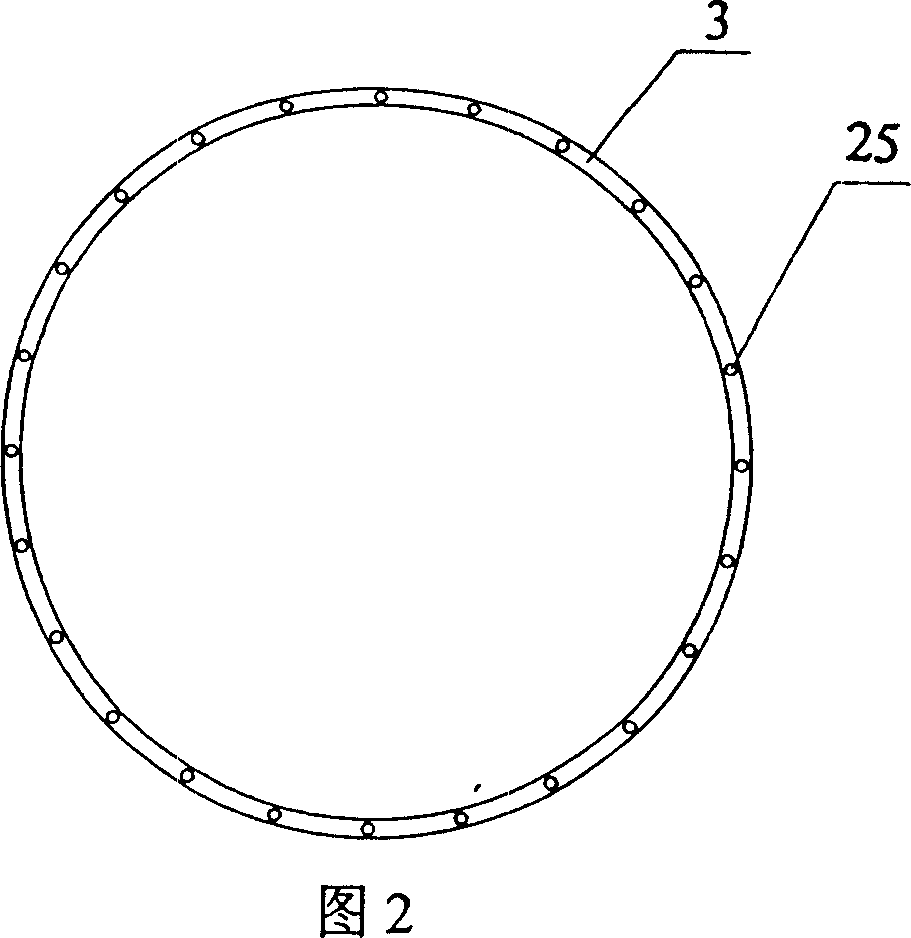

[0021] The first embodiment of the present invention is shown in Fig. 1, Fig. 2, Fig. 3, and the present invention comprises pressure oil tank 4, vacuum device, alternating pressure applying device and the inert gas filling ring that is evenly distributed with exhaust holes 3. The inert gas filling ring 3 is installed at the lower part of the pressure oil tank 4 and connected to the inert gas source 2; the vacuum pump 10 is connected to the top of the pressure oil tank 4 through the first stop valve 11 and the second stop valve 6; alternating The pressure applying device is made up of air bag 5, vacuum pump 10, first shut-off valve 11, the third shut-off valve 12, the fourth shut-off valve 7 and air filter 8, and vacuum pump 10 is connected with the first shut-off valve 11 and the third shut-off valve 12. The air bag 5 installed on the upper part of the pressure oil tank 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com