Double-rotor variable speed and frequency conversion wind power generation exciting method and control system thereof

An excitation method and excitation control technology, applied in the control of wind turbines, control systems, wind power generation, etc., can solve problems such as frequent gearbox failures, low unit efficiency, and poor working conditions of wind turbine units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

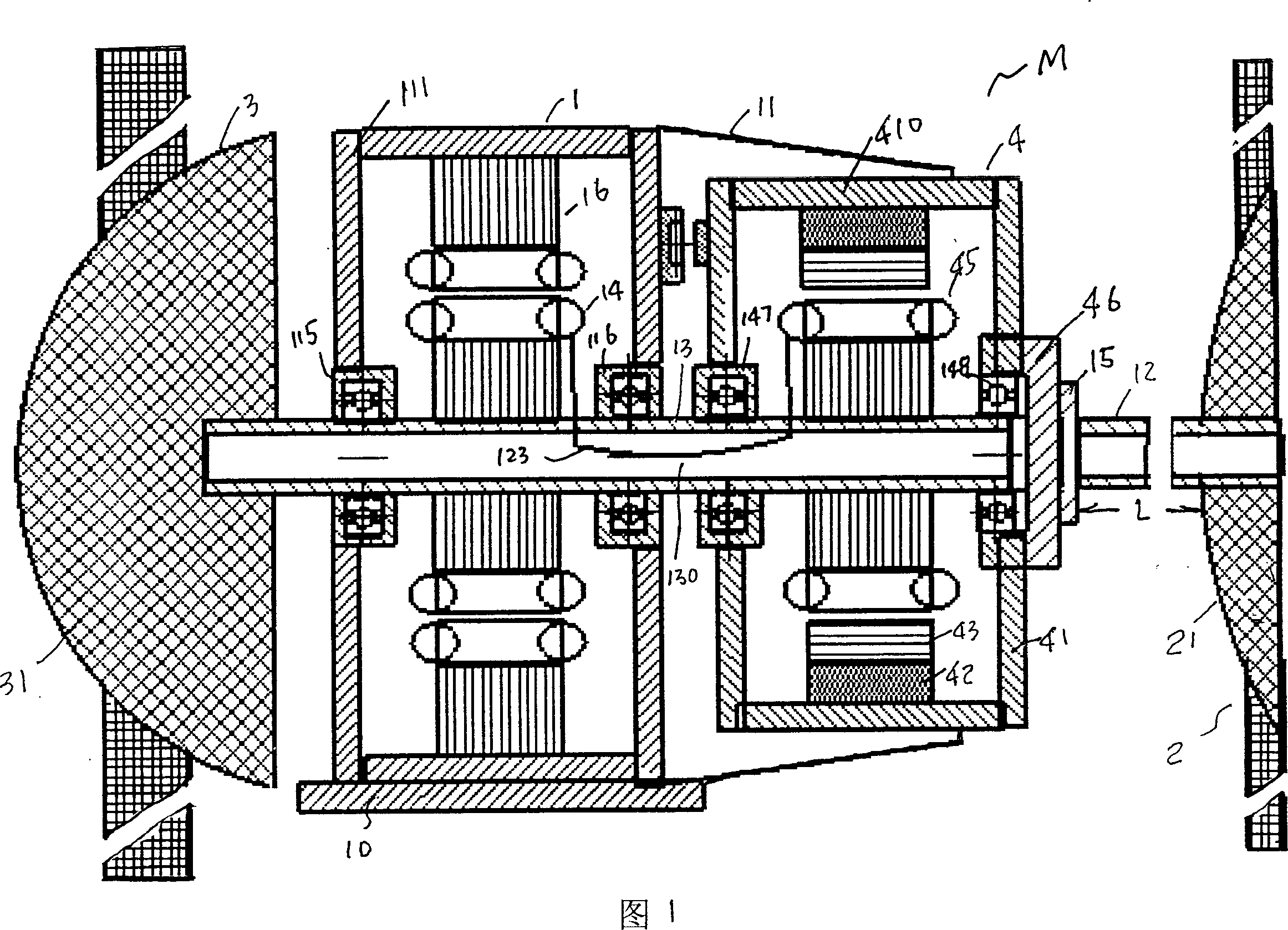

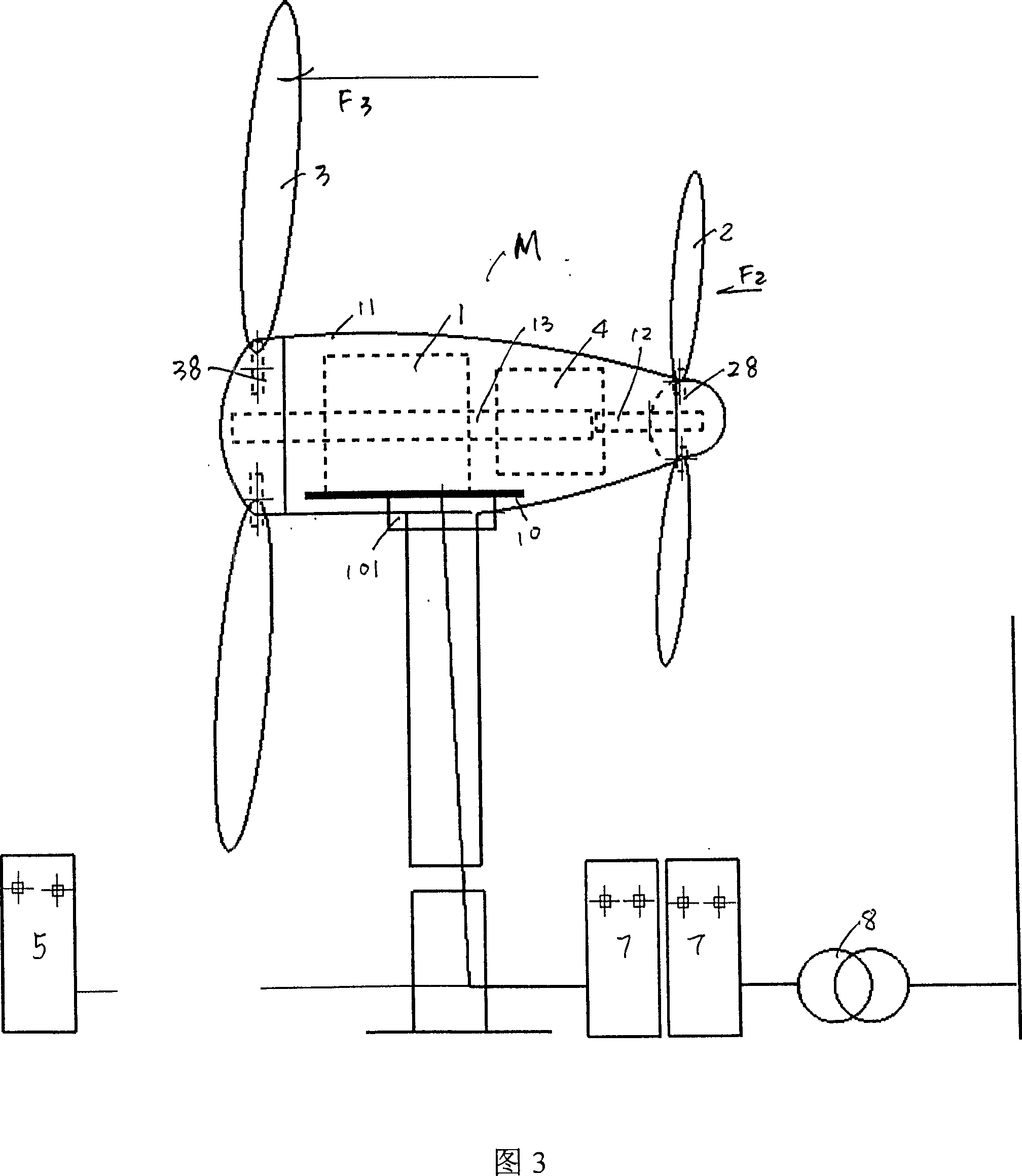

[0044] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

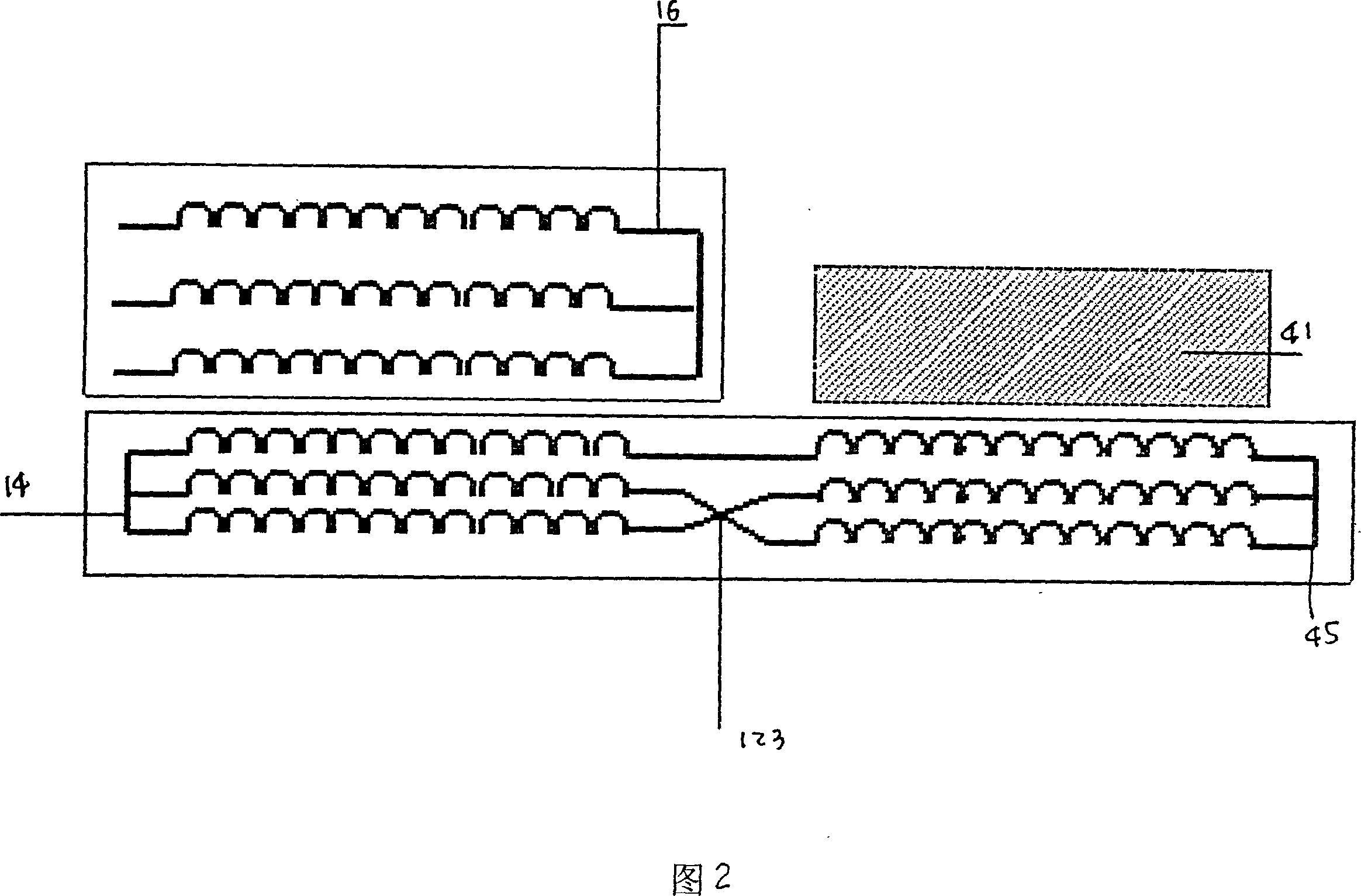

[0045] As shown in Figures 1-4, a dual-rotor variable-speed variable-frequency wind motor M includes a generator main body 1 fixed on a base 10, a generator stator 16 fixed in a motor casing 111, and a generator rotor 14 passing through the main body. The drive shaft 13 is configured to rotate relative to the stator 16, wherein,

[0046] The exciter 4 is coaxially installed in the casing through the main transmission shaft and the main body of the generator; the permanent magnet 43 is installed on the yoke 42 in the permanent magnet outer rotor housing 410 to form the permanent magnet outer rotor 41 of the exciter. The permanent magnet outer rotor is set in a structure that is relatively rotating with the exciter inner rotor 45 through the connecting piece 46; the perma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com