Atomic-force microscope needle-tip washing method and apparatus

An atomic force microscope and cleaning device technology, applied in cleaning methods and utensils, cleaning methods using liquids, measuring devices, etc., can solve the problems of complicated and time-consuming operation procedures, and achieve low scanning costs, high decontamination efficiency and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

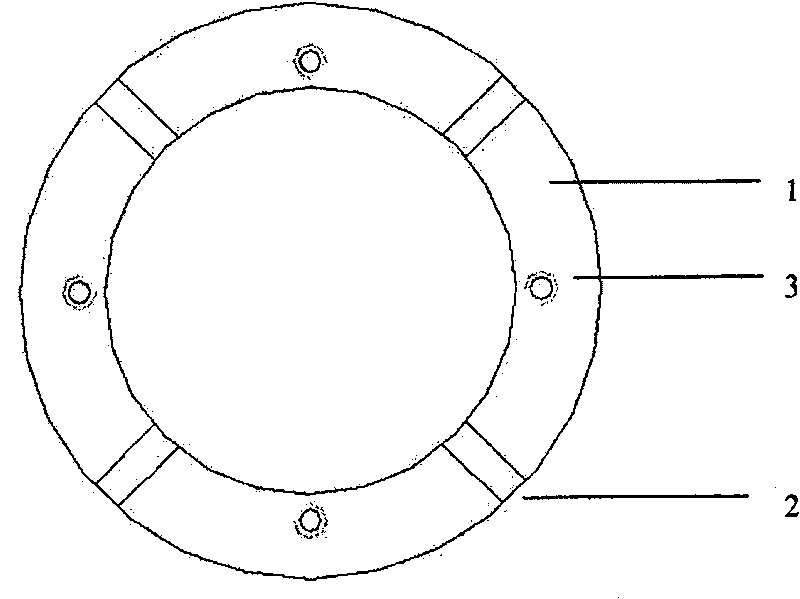

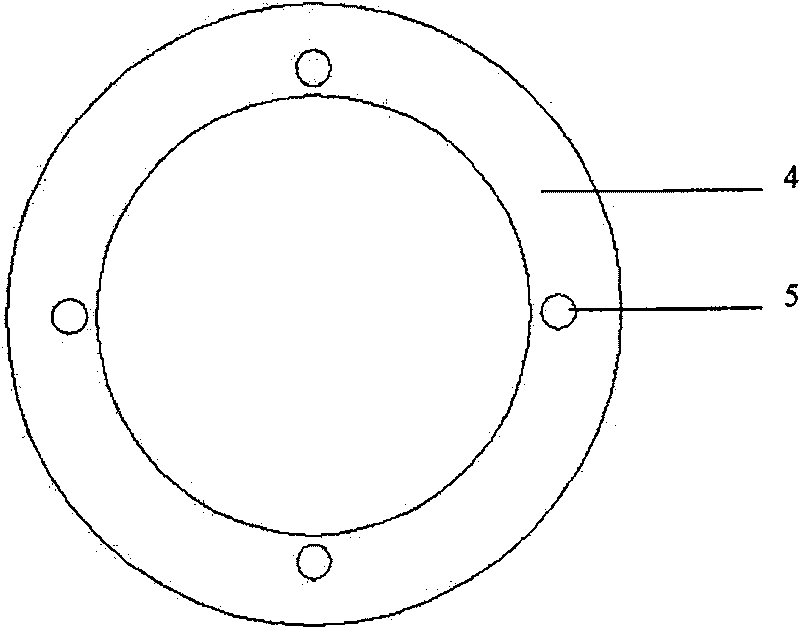

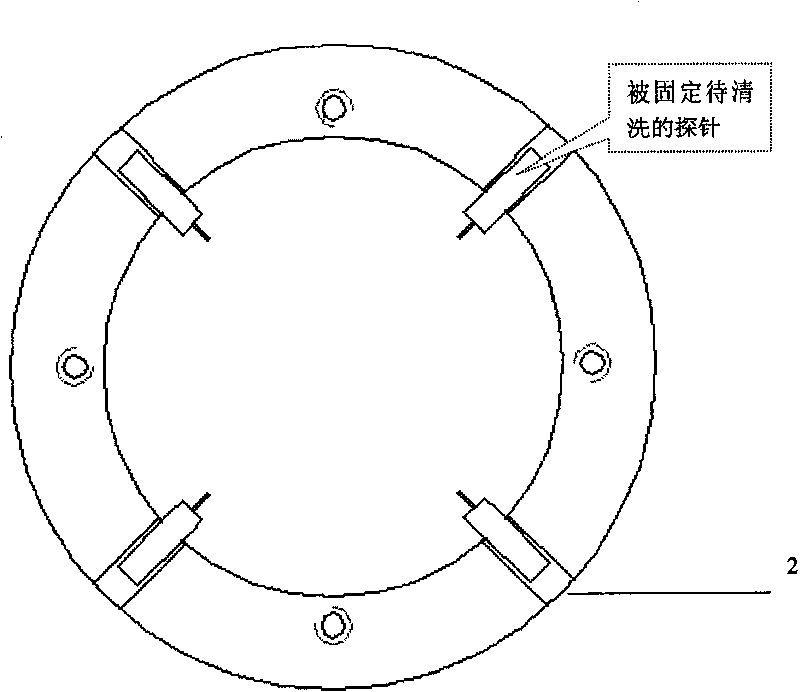

[0021] Such as figure 1 , figure 2 As shown, the cleaning device of the present invention includes two parts, an annular base [1] and an annular cover [4]. The base [1] and the cover [4] have the same inner and outer diameters, and there are multiple Groove [2], the groove [2] is slightly wider than the base of the probe, the depth is equivalent to the thickness of the probe, and is used to hold the probe. The screws go through the through holes [5] and screw holes [3] to fix the cover [4] and the base [1].

[0022] Before cleaning, first dissolve 1ml of detergent into 50ml of deionized water to prepare a cleaning solution; apply a small amount of nail polish on the back of the lower part of the probe without the needle tip, and adhere to the ring-shaped base of the cleaning device [1] In the groove [2], point one end of the probe tip towar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com