Black ink composition for aqueous ballpoint pen and aqueous ballpoint pen

A technology of ballpoint pens and compositions, applied in inks, applications, household appliances, etc., can solve the problems of insufficient black display, insufficient wear suppression of ballpoint pens, etc., and achieve smooth writing, sufficient concentration, and wear-resistant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

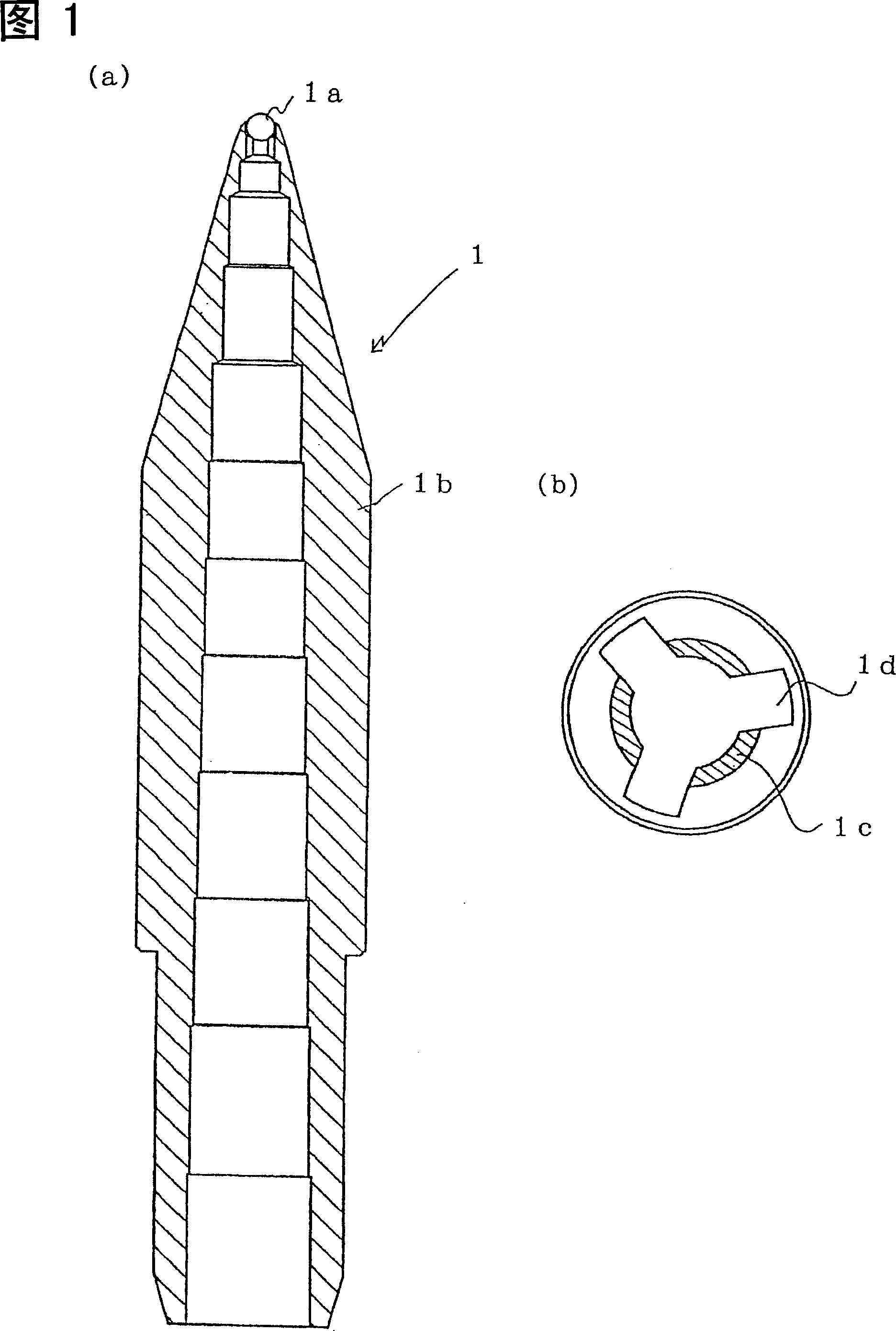

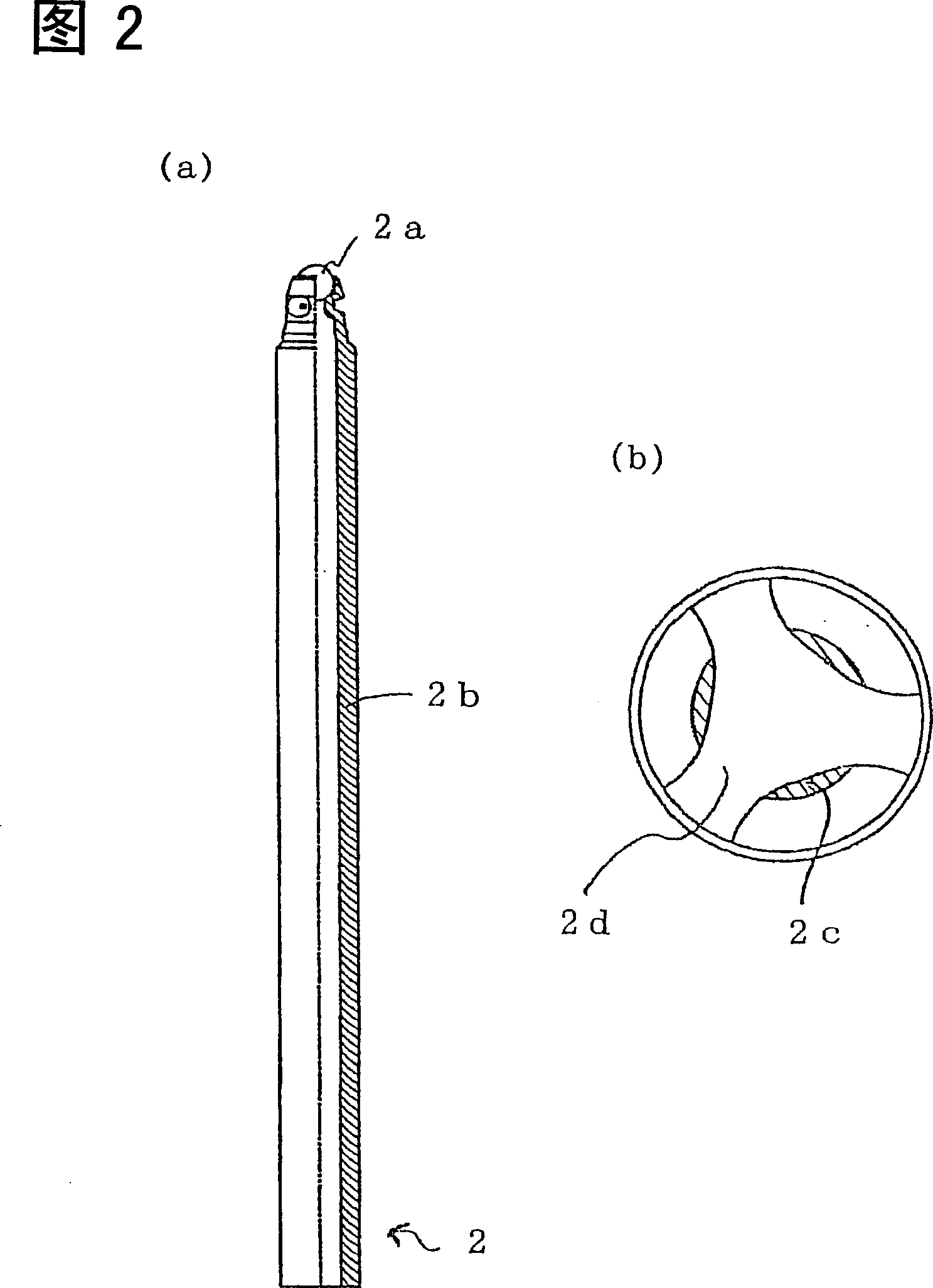

Image

Examples

Embodiment 1~14

[0053] Examples 1-14, Comparative Examples 1-6 and Reference Example 1

[0054] Use a blender to prepare the color materials shown in the following table 1 (by mixing 2 or more pigments with different C.I. names to obtain the color color materials A~E) and each ink component according to the following table 2 The mixed composition of Table 3 (mixing unit: % by weight, total amount: 100% by weight) was uniformly dispersed. Aqueous ink compositions corresponding to Examples 1 to 14, Comparative Examples 1 to 6, and Reference Example 1 were obtained.

[0055] For each of the obtained aqueous ink compositions, the ink pH (25° C.) was measured using a pH meter F-24 manufactured by Horiba Corporation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com