Workpiece standard operation program file management system and method

A standard operation and program file technology, applied in the field of workpiece standard operation program file management system, can solve problems such as inability to realize resource sharing, achieve the effect of reducing human misoperation and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

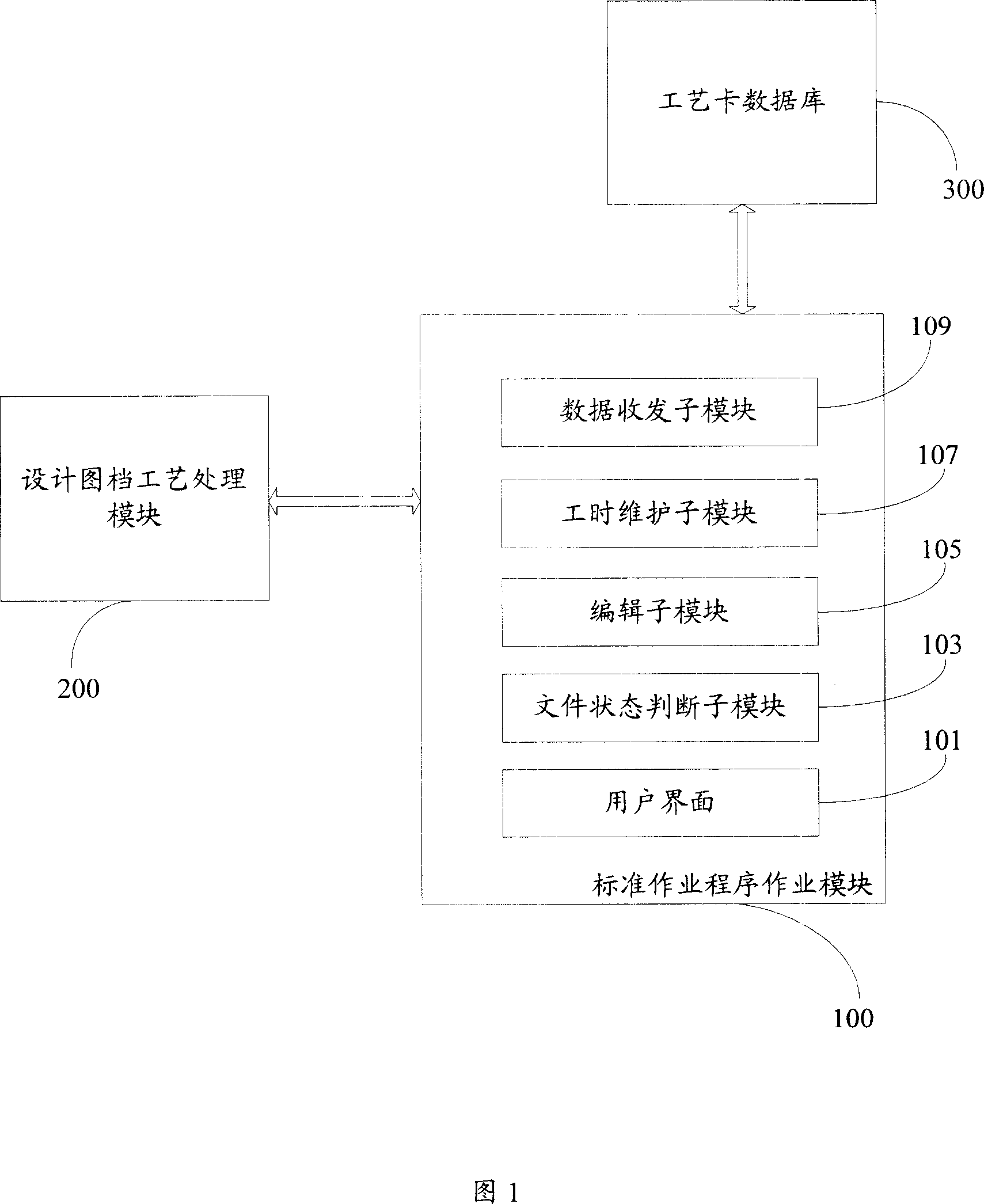

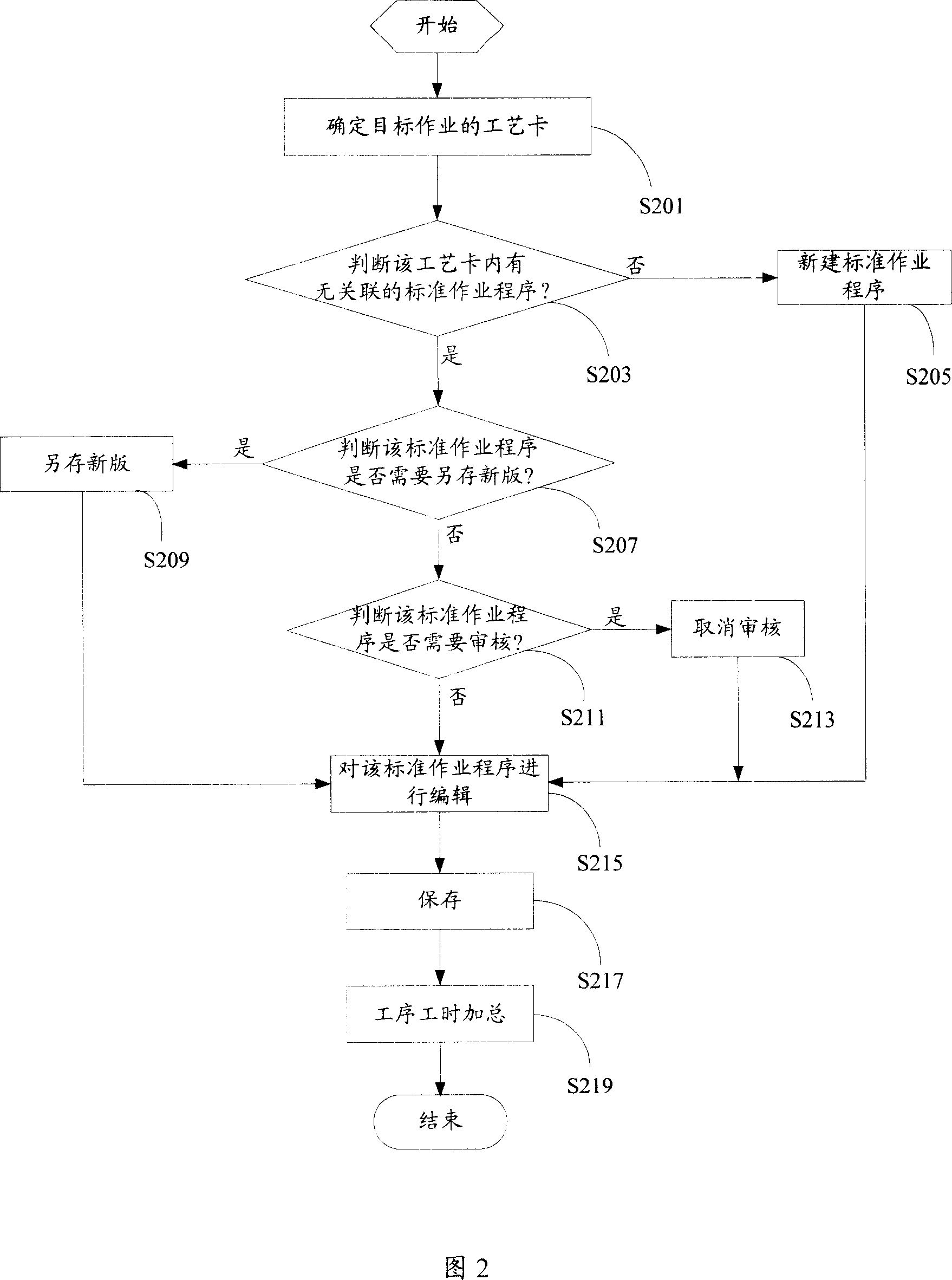

[0012] Referring to FIG. 1 , it is a block diagram of the workpiece standard operating procedure file management system in the embodiment of the present invention. The panel standard operating procedure file management system includes a standard operating procedure (Standard Operating Procedure, SOP) operation module 100 , a design drawing process processing module 200 and a process card database 300 . Both the process card database 300 and the design drawing file process processing module 200 are communicatively connected with the standard operating procedure operation module 100 .

[0013] The process card database 300 is used to save the process card data of various products.

[0014] The design drawing process processing module 200 is used to expand the workpiece design drawing to generate a process drawing, and generate a processing station drawing according to the process drawing, then generate a standard operating procedure file for workpiece processing from the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com