Semi-closed observing environment for electronic microscope

An electron microscope, semi-closed technology, used in circuits, discharge tubes, measuring devices, etc., can solve the problems of sample flow, unable to penetrate the sample, and the electron beam cannot be smoothly imaged, and achieve the effect of easy observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to describe the structure and characteristics of the present invention in detail, the following three preferred embodiments are given below and described in conjunction with the accompanying drawings. Among them, the three embodiments describe that the film is arranged in the observation hole, and the film is arranged in the air hole, and the film is arranged in the air hole. It is set in the state of the outer hole, and it is a semi-closed observation environment.

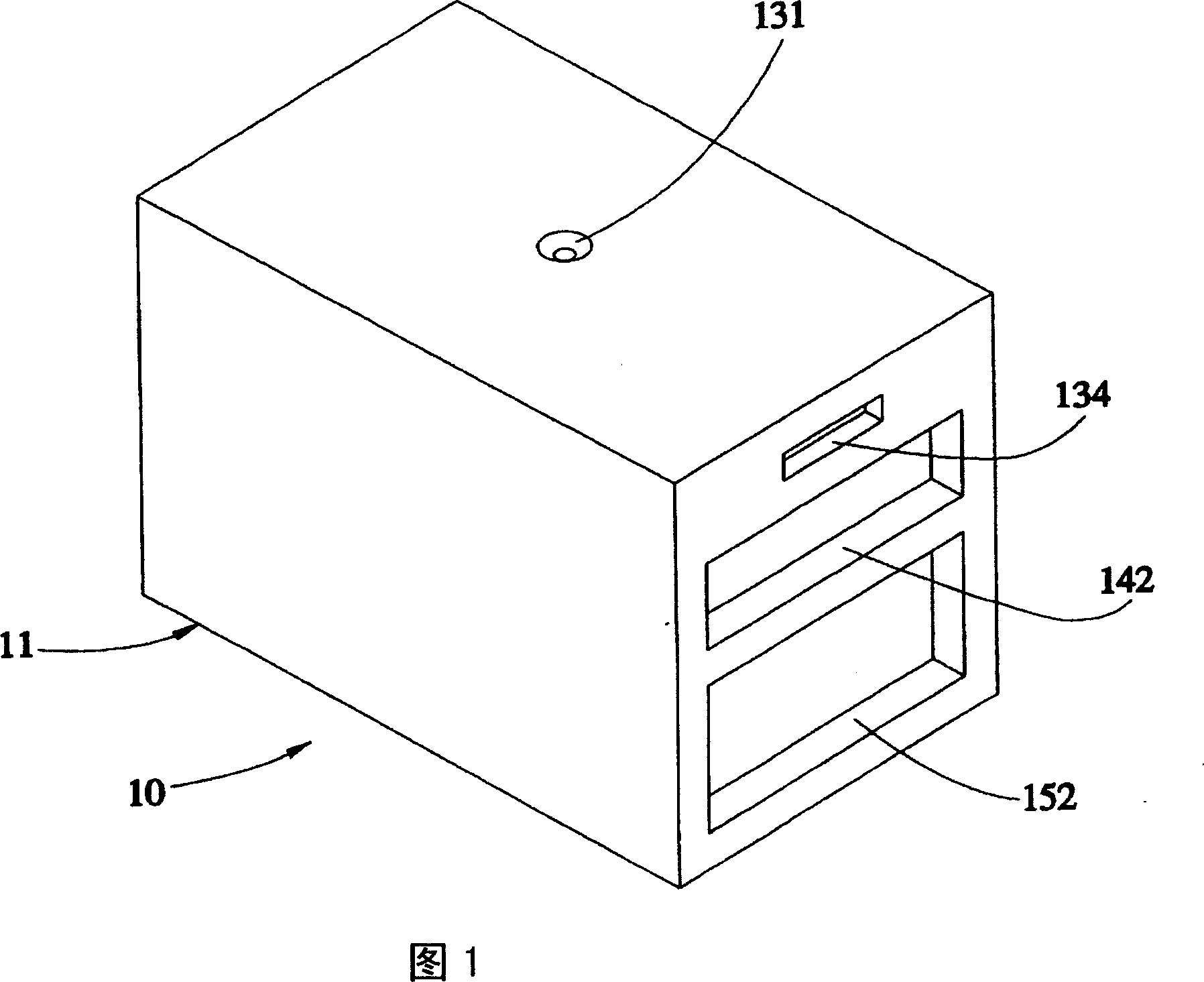

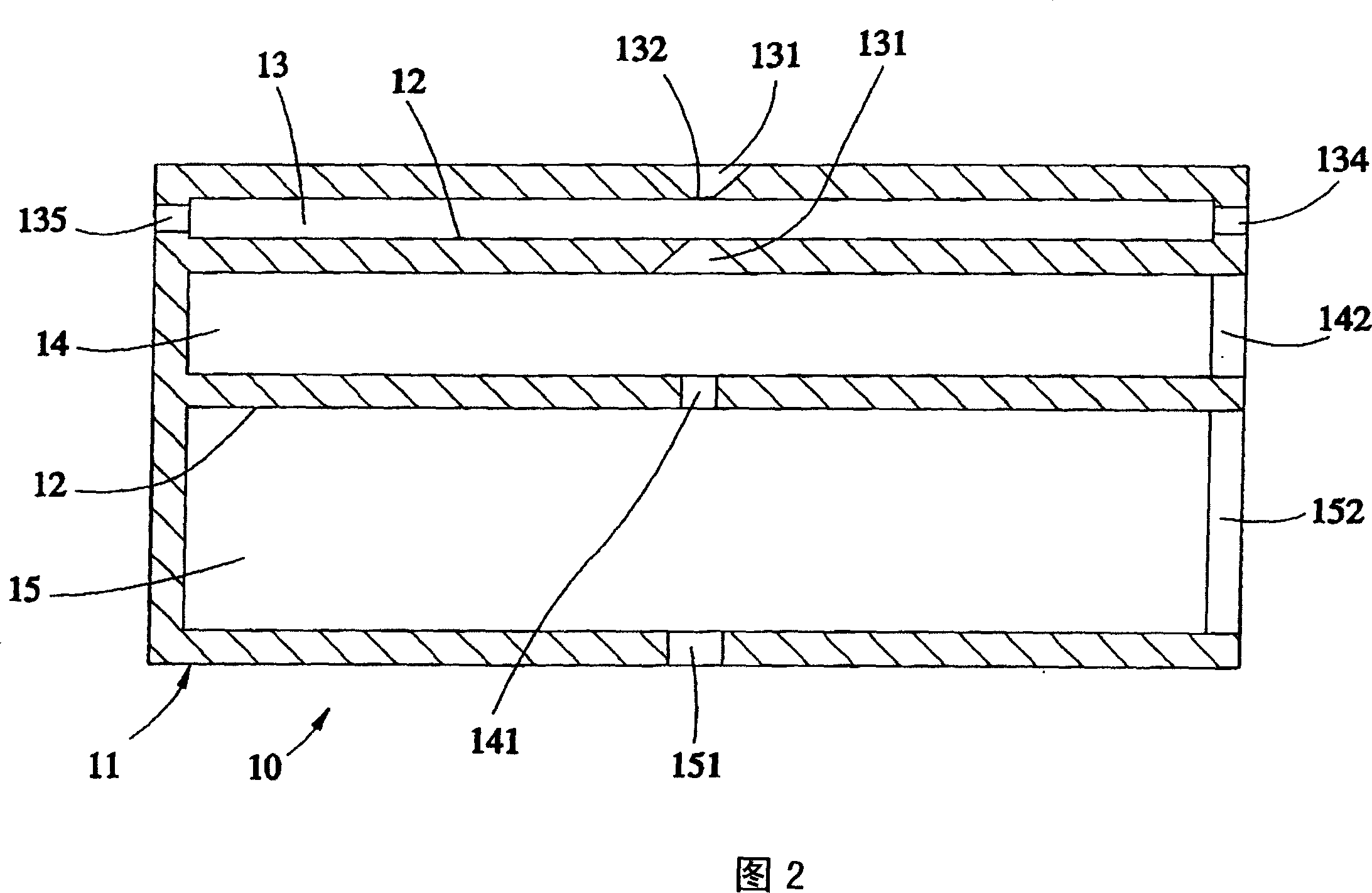

[0040] As shown in Fig. 1 to Fig. 3 (A) figure, the semi-enclosed observation environment 10 that a kind of electron microscope provided by the first preferred embodiment of the present invention mainly has:

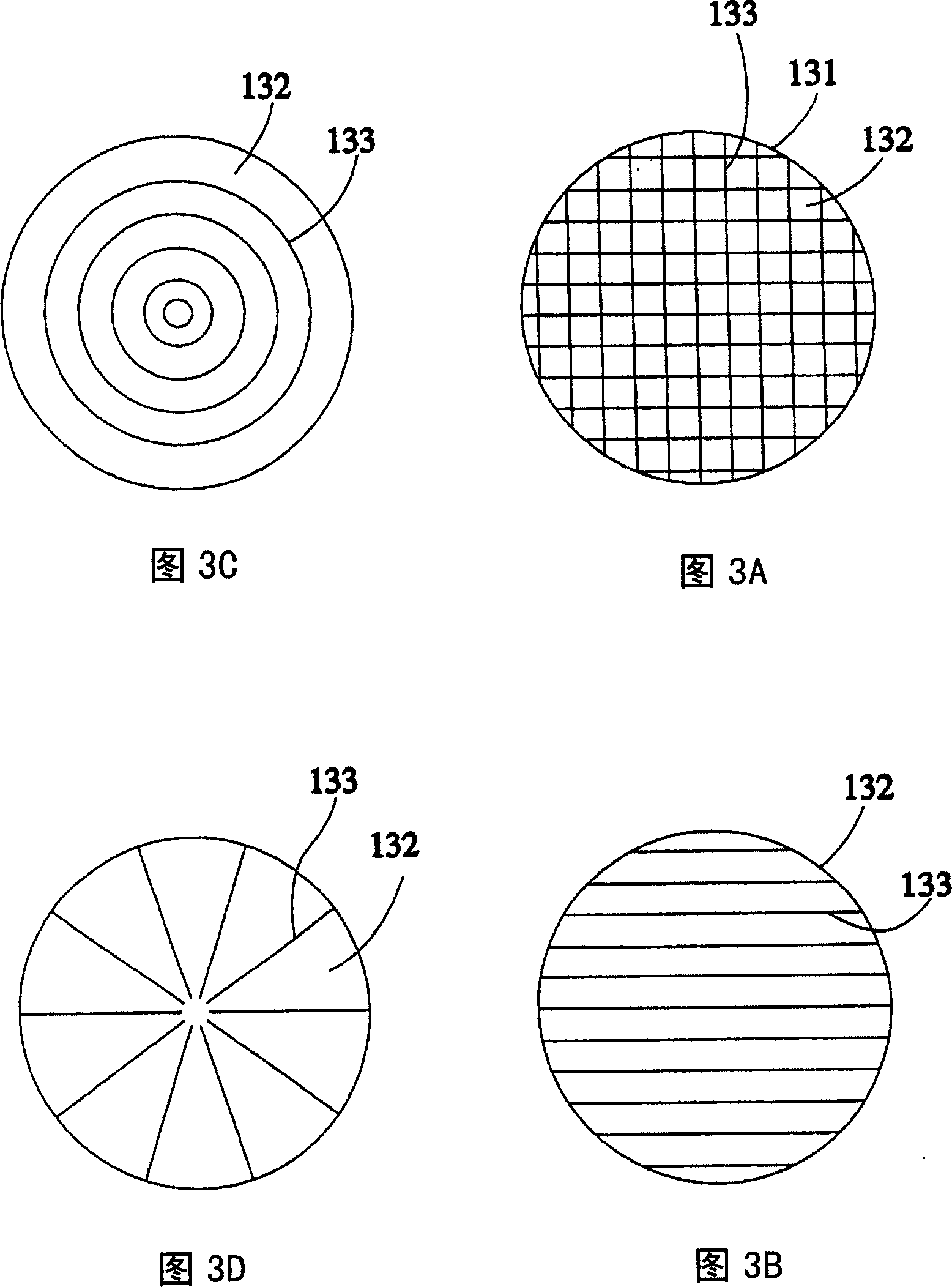

[0041]A housing 11, the interior is separated by at least two partitions 12 to form a chamber 13, and an air chamber 14 below the chamber 13, and a buffer chamber 15 below the air chamber 14, the chamber 13 There is at least one viewing hole 131 on the top surface of the housing 11, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com